Power node/acm certifi cation – Alpha Technologies APU Control Module (ACM) User Manual

Page 27

27

018-340-B0-001 Rev. A

5.0

System Self-Test and Maintenance, continued

5.2

System Maintenance, continued

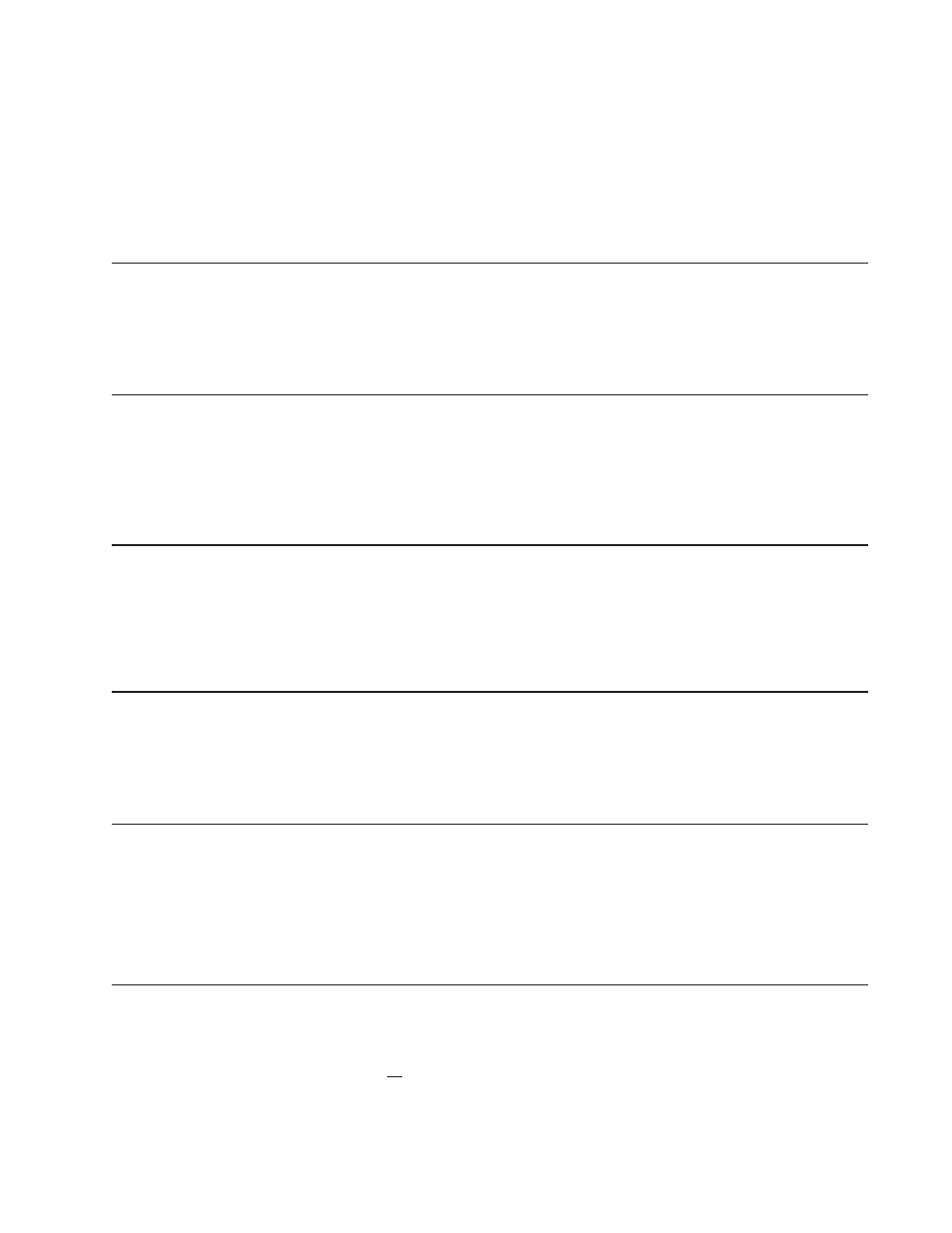

Power Node/ACM Certifi cation

Power Node Location___________Node____________

Model#____________

Technician______________Date ____________

Serial #___________

Ignition Battery Check (Record

Results)

Verify correct Ignition Battery and Charger cables attachment ........................................................... Pass / Fail

Verify Battery Terminal surfaces clean, tight, and covered with

approved corrosion inhibitor (NCP-2)

.................................................................................... Pass / Fail

Battery Voltage Range 12.5-14.1Vdc.

.................................................................................... Actual= _____

Verify Enclosure Fan Running? *See note 1 .................................................................................... Pass / Fail

ACM Interface Checks

Line sense Voltage. *See note 2

........................................................................................ Actual = ________

Line sense Frequency Range 60Hz +/- 1Hz. *See note 2 .................................................................. Actual = ________

Verify all connectors correctly installed and locked into place. ............................................................ Pass / Fail

Run-Auto-Stop (RAS) rocker switch set to Auto. *See note 3 ............................................................ Pass / Fail

Verify Pad Shear Magnet is correctly installed. ................................................................................... Pass / Fail

Verify Gas Detector is correctly installed. Pass / Fail

Verify Water Intrusion sensor is correctly installed. ............................................................................. Pass / Fail

ACM Alarm Verifi cation

Verify no Major alarms are reported.

.................................................................................... Pass / Fail

Verify the only Minor alarm reported is “Tamper” (Enclosure Door Open).......................................... Pass / Fail

Water Intrusion Sensor (Hold fl oat up to activate major alarm). .......................................................... Pass / Fail

Pad Shear Sensor (Place metal object between sensors to activate major alarm). .................................... Pass / Fail

Gas Detector (Disconnect to activate alarm).

.................................................................................... Pass / Fail

Verify Line Failure Notifi cation by disconnecting Line Sense. *See Note 4 ...................................... Pass / Fail

Verify DC Bus Fault alarm by disconnecting Battery Sense. *See Note 5 ........................................ Pass / Fail

Generator Functional Verifi cation

Verify oil clean and fi lled to capacity.

.................................................................................... Pass / Fail

Verify air fi lter clean and installed.

.................................................................................... Pass / Fail

Verify no oil leakage from oil fi lter, drain plug, and oil fi ll tube. ............................................................ Pass / Fail

Perform one minute self-test. *See note 3

.................................................................................... Pass / Fail

Engine does not “hunt” excessively during idle/no load conditions. .................................................... Pass / Fail

Enclosure properly grounding.

.................................................................................... Pass / Fail

Power Supply Verifi cation

XMS2 Power Supply checked per section 5 of the operator’s manual ................................................ Pass / Fail

Battery pack voltage (no load, generator off) range.

*See note 6, note 7

.................................................................................... Actual =________

Battery Terminals clean, tight, and covered with approved

corrosion inhibitor (NCP-2).

.................................................................................... Pass / Fail

Service Entrance, Enclosure, and Power Supply grounded properly. ................................................. Pass / Fail

Successful completion of 10 minute Self-test. .................................................................................... Pass / Fail

No Major or Minor alarms reported on XMS2 Smart Display. .............................................................. Pass / Fail

NOTES:

.

1. During initial installation, the fan will completely discharge the ignition battery if utility power is not available.

2. Verify via status monitoring.

3. Each time the RAS switch is placed in Auto, a one minute self-test is performed.

4. The generator will not start unless a line failure is greater then 10 minutes.

5. The generator will start immediately and run for a minimum of 30 minutes (Use RAS to stop Gen).

6. The difference between any battery in the string should not exceed 0.3 Vdc under load (XMS2 self-test).

7. Typical battery pack voltage ranges are 39.6-42.3Vdc, 52.8-56.4Vdc, and 105.6-112.8Vdc for 36/48/96 volt systems, respectively.