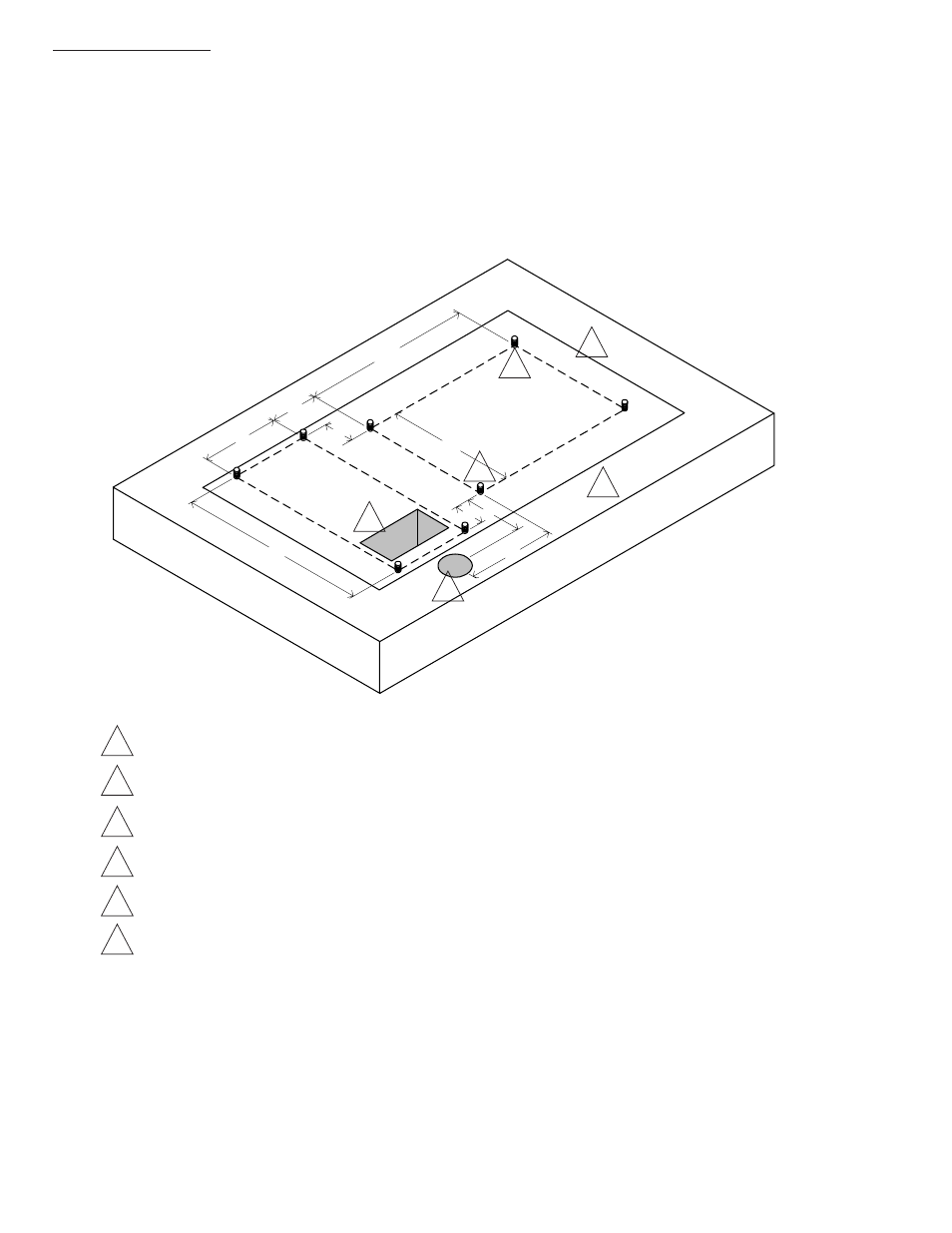

Installation fig. 2 pad layout – Alpha Technologies CESC User Manual

Page 10

5.5

9.2

3.5

3.5

22.0

CESC

Generator

or PN3/4

10.25

6.8

All Measurments

in Inches

19.5

14.7

Pads can either be poured on site, or precast by Alpha Technologies. The mounting holes on

the bottom of the high security PN-3 will fit both a standard PN-3 pad, and a CE3X pad.

Precast pad model number PCC-SC-3X, Alpha P/N 641-061-10 or PCD-SC-3X, Alpha P/N

641-064-10 (east coast) are available for this system.

All measurements are indexed to the front left generator mounting stud.

Indicates outline of enclosure.

Alpha standard; recommended distance (6" minimum) between edge of pad and cabinet.

Four inch diameter hole for AC power IN (non-metered installation).

All mounting hardware must be stainless, galvanized, or better to prevent corrosion.

5" x 8" rectangular cutout for all internal connections including: generator power and/or coax

cable conduit sweeps. Position between mounting studs not critical.

A 25+ year continuous vapor barrier must be used between the enclosure and the pad to

prevent moisture ingress and possible corrosion caused by metal to concrete contact.

The vapor barrier material (such as 30 lb felt, neoprene pond liner, or heavy grade tar

paper) must be initially extended at least 6" in all directions around the perimeter of the

enclosure. After the enclosure is secured to the pad, the material can be cut closer to

the enclosure, using the appropriate knife or cutting tool.

5

6

1

2

3

4

2.1

Concrete Pad Preparation

1

2

3

4

5

6

10

031-106-C1-001 Rev. A

2. Installation

Fig. 2 Pad Layout