Emission control information – Alpha Technologies AlphaGen DCX2000 - Operator's Manual User Manual

Page 19

19

041-135-B0-001 Rev. A (07/2013)

3.0

Servicing, continued

3.1 Emission Control System, continued

Replacement Parts and Accessories

The parts making up the emission control system have been specifically approved and certified by

the regulatory agencies. Replacement parts supplied by Alpha have been manufactured to the same

production standard as the original parts. The use of replacement parts or accessories which are not

designed by Alpha may affect the engine emission performance. The manufacturers of replacement parts

and accessories have the responsibility to guarantee that their replacement products will not adversely

affect emission performance.

Maintenance

Maintain the generator according to the maintenance schedule in

Section 4.2, Maintenance Schedule.

Service items more frequently when used in dusty areas, or under conditions of high load, temperature,

and humidity.

Air Quality Index

CARB requires that an air quality index label be attached to every certified engine showing the engine

emission information for the emission duration period. The label is provided for the user to compare

the emission performance of different engines. The lower the air index, the better the engine emission

performance. The description of durability is helpful for the user to learn the engine emission duration

period and the service life of emission control system. Refer to the warranty section of this Owner’s Manual

for more information.

The air quality index label is designed to be permanently affixed to the generator and removal should not

be attempted.

The generator has an engine that has been approved by the California Air Resources Board. Other than

the tune up procedures specified in the maintenance section, no additional maintenance is required.

The emission control system has the following components:

1. Fuel System: The fuel tank, cap, indicator and hoses are specially designed and constructed to not

allow fuel vapors to permeate and be released to the atmosphere.

2. A carbon activated canister collects gasoline vapors from the fuel tank and returns them to the

combustion chamber for burning.

3. A catalyst is built into the muffler to further treat the engine exhaust.

4. A secondary air injection valve adds combustion air to ignite unburned fuel in the exhaust.

Contact Alpha to obtain the correct replacement parts and service on this system.

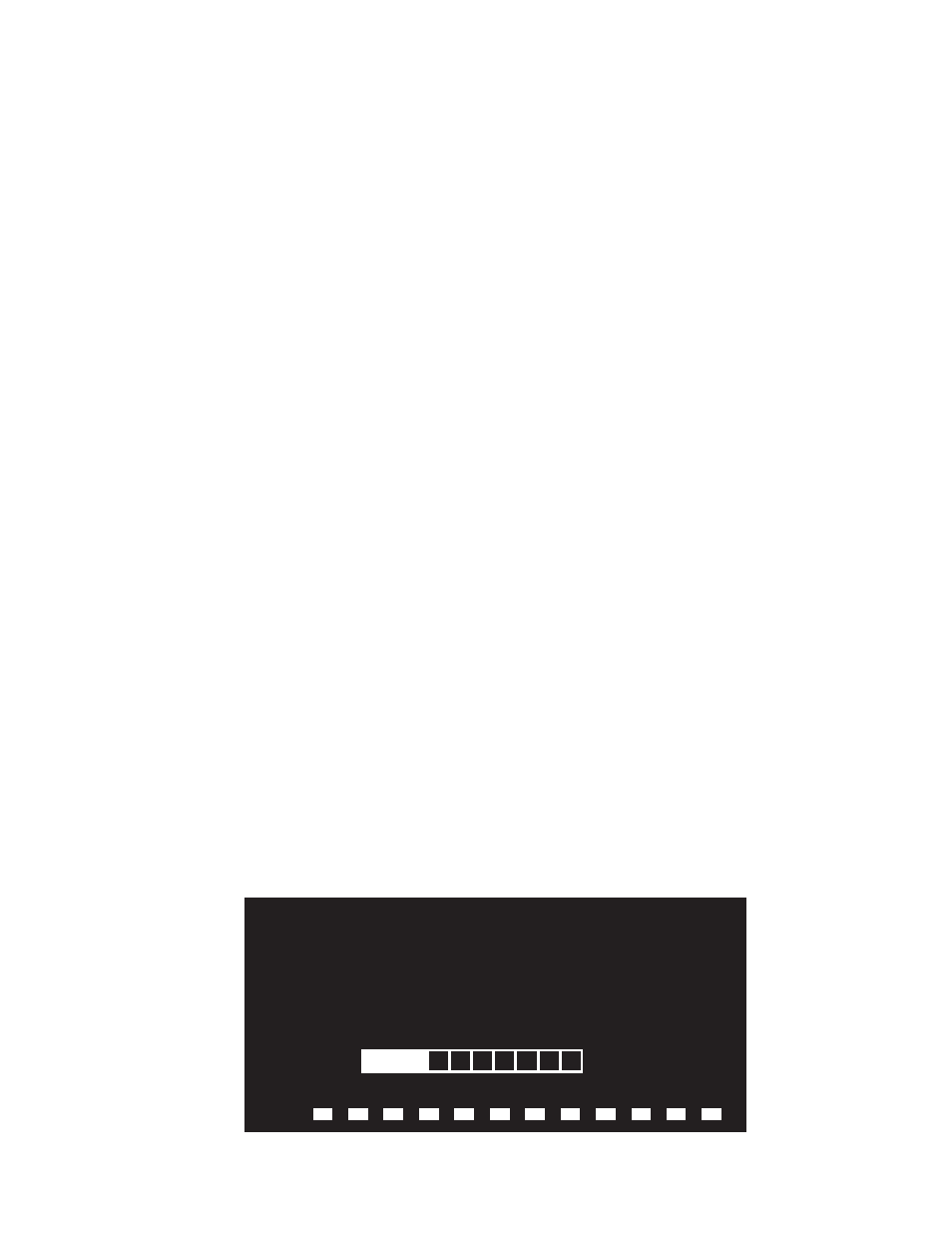

Fig. 3-1, Air Quality Index Label

EMISSION CONTROL INFORMATION

YONGKANG XINGGUANG ELECTRICAL MANUFACTURE CO., LTD.

THIS ENGINE IS CERTIFIED TO OPERATE ON UNEADED GASOLINE. THIS ENGINE MEETS U.S.

EPA CALIFORNIA AND EVP EMISSION. REGULATIONS FOR SMALL OFF-ROAD ENGINES

FOR 2012 MODEL YEAR. ENGINE FAMILY: CYKXS.1251XG DISPLACEMENT: 125 CC EVAP

ECS CM CARB EVAP FAMILY: CM EPA EVAP FAMILY: CXKXPNHEQOO1 LUBRICANT

REQUIREMENTS: SF15W-40 EXH ECS: TWC+PAIR EMISSIONS COMPLIANCE PERIOD: 125 HOURS

THE AIR INDEX OF THIS ENGINE IS 3

MOST CLEAN

LEAST CLEAN

0

2

4

6

8

10

DATE OF MANUFACTURE:

2012 01

02

03

04

05

06

07

08

09

10

11

12