Bolt switch contact, Assembly on side of lock bolt blank, Strike plate contact, closing detector) – ABUS RS1000 Bar switching contact User Manual

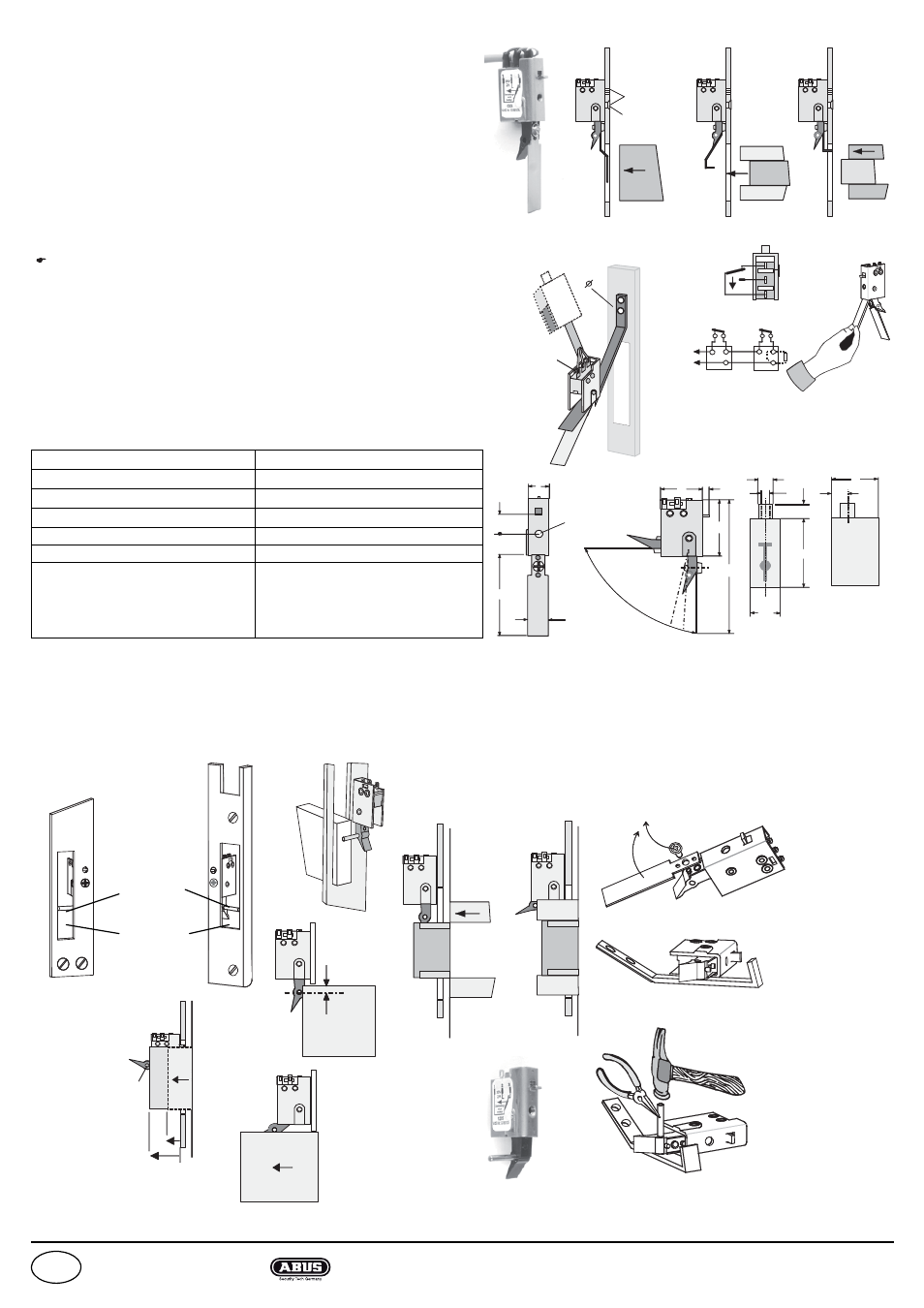

Page 2: Inserting straight pin

ca 4 mm

1

2

3

2 x 3,2mm

1

2

3

Bolt switch contact

(Strike plate contact, closing detector)

Assembly instructions

•

Determine fastening position for the bolt switch contact.

New feature: Possibility of assembling on side of bolt blank! (Patent!)

•

Adjust lever arm as required as shown in the examples in Figure 1, 2 or

Figure 3, or insert straight pin for assembling on side of bolt blank re-

spectively.

•

Glue drilling jig to the fastening site and drill 3.2 mm hole (2x). Figure 4.

In the case that a cable is soldered leave drilling jig for this step.

•

Depending on the application, route the connecting cable through the

cover.

•

If the version without connection cable is built, place bolt switch contact

on the angled part of the drilling jig. Figure 4. Manufacture soldered joint

in accordance with the circuit diagram. Fig. 5.

Micro switch housing is waterproof! IP 67! Connections IP 50 Seal soldered

connection if necessary or protect against moisture with a heat-shrinkable tube.

•

Remove bolt switch contact and drilling jig.

•

Create countersinking for countersunk fastening screw (M3).

•

Remove adhesive strip from drilling jig.

•

Place housing on jig (assembly aid). Figure 6

•

Put bolt switch contact in the fastening position.

•

Fasten with M3 countersunk screw provided.

NOTE! The correct screw length is calculated from the depth of the thread of the

bolt switch contact = 2 mm plus the material thickness of the strike plate!

A screw with excess length will cause a malfunction!

Technical data

VdS - Nr. G 186 105 Class C

Figure 1

Figure 2

Figure 3

NEW!

Assembly on side of lock bolt blank

Use of cover (outer doors)

Route cable through the opening in the cover before or

after soldering according to cable routing!

If there is no cover, fasten cable to housing using cable

ties.

Protection against moisture and dirt is only ensured if

the cable outlet is at the top!

Distributors

Assembly aid /

drilling jig

Switching point

10° - 15°

"Straight pin"

as additional

actuator

Bolt opening

on "striking

plate / door

frame"

Straight pin

If the initial actuation

is approximately

4 mm from the edge

of the bolt, the bolt

alignment distance

is unlimited!

Inserting straight pin

Remove fastening screw

and

remove sheet metal plate

Place bolt switch

contact on a flat

surface and insert the

drilling jig underneath

the switch actuator to

protect the surface of

the substrate!

Insert straight pin

until it is flush with the

underside of the switch

actuator.

Further example of an

application

Drilling jig

Subject to changes! Date: January 2008

Figure 4

Figure 5

Figure 6

Latch

Bolt

Control

unit

Housing, spring and lever arm

X12CrNi177 1.4310 (stainless steel)

Micro switch (changeover contact)

Gold contact 1 mA – 2 A / 30 V

Temperature range

-40 °C to +65 °C (VdS Class III)

Air humidity

Max. 95 % relative

IP rating: micro switch / connection

IP 67 / IP 50 sealed connection IP67

with cover

IP 64

Scope of delivery

(Version with LIYY 3x0,14 mm

2

connecting cable, grey Ø3,4mm

length 2m tin-coated, suitable for

LSA-Pus IDC termination technology.)

Bolt switch contact; cover; drilling; jig;

1 DIN 965 countersunk screw and A2

recessed head screw (stainless steel)

in each of the following sizes M3x5,

M3x6, M3x8, M3x10

Figure

w

ith conne

cting cable

LIYY cable

3 = white

2 = green

1 = brown

Bolt

Bolt

Bolt

Bolt

Ø 3,2mm

Screw length

= material thickness

of strike plate + 2 mm

Bolt

Bolt

Version with

connecting cable

LIYY 3x 0,14mm

2

white = 3

green = 2

brown = 1

Possible strain

relief

with cable ties

R

E

1

1

2

2

Bolt switch contacts

1

2

3

Representation in

non-actuated state

8

3

4

5

8

,7

7

,5

M3

16

3

5

7

2

3

11,5

5,5

3,3

2

8

6

18

7

Cover!

Protection against

moisture and dirt

only ensured if the cable

outlet is at the top!

90° countersinking

screw head

Ø 5,5mm

Switching

point after

approx. 8mm

Max. bolt alignment distance

in bolt opening 19 mm

RS1000

Security-Center GmbH & Co. KG www.security-center.org

GB