Elmo Rietschle L-BV5 Operating instructions User Manual

Page 28

Maintenance

610.44440.40.000

28 / 32

© Gardner Denver Deutschland GmbH

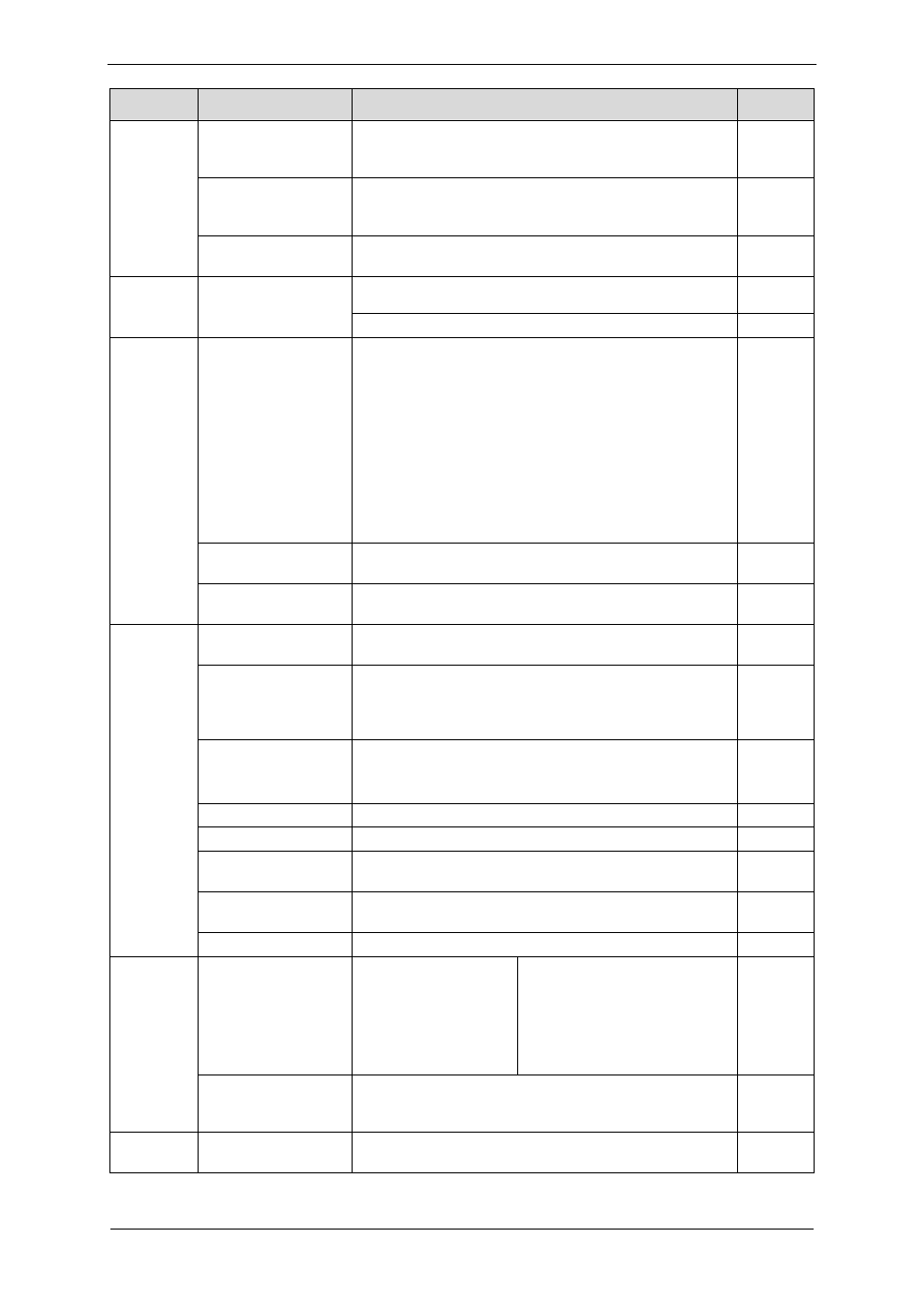

Fault

Cause

Correction

Remedy

Excessive backpres-

sure in the discharge

connection

Reduce the backpressure.

Operator

Proportion of liquid

entrained in the main

flow is too high

Reduce the proportion of liquid.

Operator

Impeller does not ro-

tate freely

See "Impeller does not rotate freely", page 27

See "Decalcifying the unit", page 26.

Operator

Power con-

sumption

too high

Build up of lime-scale

or

contamination

See "Flushing the pump casing", page 26.

Operator

No operating-liquid

supply

When operating with supply of the operating-liquid:

Check and correct the operating-liquid flow-rate. (see

chapter 7.4, "Checking and correcting the operating-

liquid flow-rate, page 22).

When operating with self-suction of the operating-liquid:

See 7.3, "Operation with self-suction of the operating-

liquid", page 22.

Clean out the operating-liquid supply hose.

Increase the diameter of the operating-liquid supply

hose.

Operator

Large-scale leak in the

system.

Seal off leaks in the system.

Operator

Unit does

not generate

a vacuum

Incorrect direction of

rotation

Change the direction of rotation by switching polarity

between two of the electrical power supply phases.

Electrician

Insufficient operating-

liquid

See "No operating-liquid supply", page 28.

Operator

Operating-liquid too

warm

cool the operating-liquid or increase the flow-rate (see

chapter 7.4, "Checking and correcting the operating-

liquid flow-rate", page 22).

(nominal temperature: 15°C [59 °F]).

Operator

Erosion / Corrosion

Inspection of the casing, the impeller and the control

disk.

Renew the affected components.

Service

Leakage in the system Repair leakage in the system.

Operator

Rotary seal leaking

Replace

rotary

seal.

Service

Motor connection in-

correct

Check and repair motor connection.

Electrician

Electrical power sup-

ply incorrect

Check and repair electrical power supply.

Electrician

System

generates

too little

vacuum

Unit is too small

Install a larger unit.

Operator

Cavitation in the unit 2BV2 … and 2BV5 1..

Connect

separator

cavitation-protection

hose (ancillary) or

clean out cavitation-

protection system.

2BV5 4..

Check that the pressure set-

ting is in accordance with the

permitted operating pressure.

Operator

Squealing

noises

Operating-liquid flow-

rate too high

Check the operating-liquid flow-rate and if necessary

reduce it (see chapter 7.4, "Checking and correcting

the operating-liquid flow-rate", page 22).

Operator

Leakage in

the unit

Defective seals

Check

the

seals.

Service