Rietschle thomas gmbh + co. kg page – Elmo Rietschle R-WPB User Manual

Page 9

Rietschle Thomas GmbH + Co. KG

page

9

/

23

Blowers are used to transport and compress gases. Since

the rotors neither touch each other nor are in contact with

the casing, blowers are suitable for oil-free transport and

gas compression. During transport, media are not

contaminated with either abrasion particles or oil.

Standard blowers are designed to compress or exhaust air

or non-aggressive and non-explosive gases. If you may

need further assistance in using the blower with special

gases, please contact Rietschle Thomas.

Suction and discharge temperatures depend on the

compression degree. Both temperatures are stated in the

calculation of the blower set parameters. Such calculations

are included in the offers of the blower sets. In standard

blowers, the maximum temperature of the discharged

medium is 140 °C. In order to prevent the temperature from

exceeding the limit value in the discharge section (even

during the highest medium compression), the intake

medium temperature must be below 40 °C.

The suction and discharge pressures are stated on the type

plates of the blower sets and in the calculations of the

blower set parameters. The maximum permissible

differential pressure is stated on the blower type plates. The

pressure at the blower’s discharge flange is referred to as

p

v

, the pressure at the blower’s suction flange is referred to

as p

s

, and the pressure at the flange that connects the

blower set with the pipeline system is referred to as p

3

.

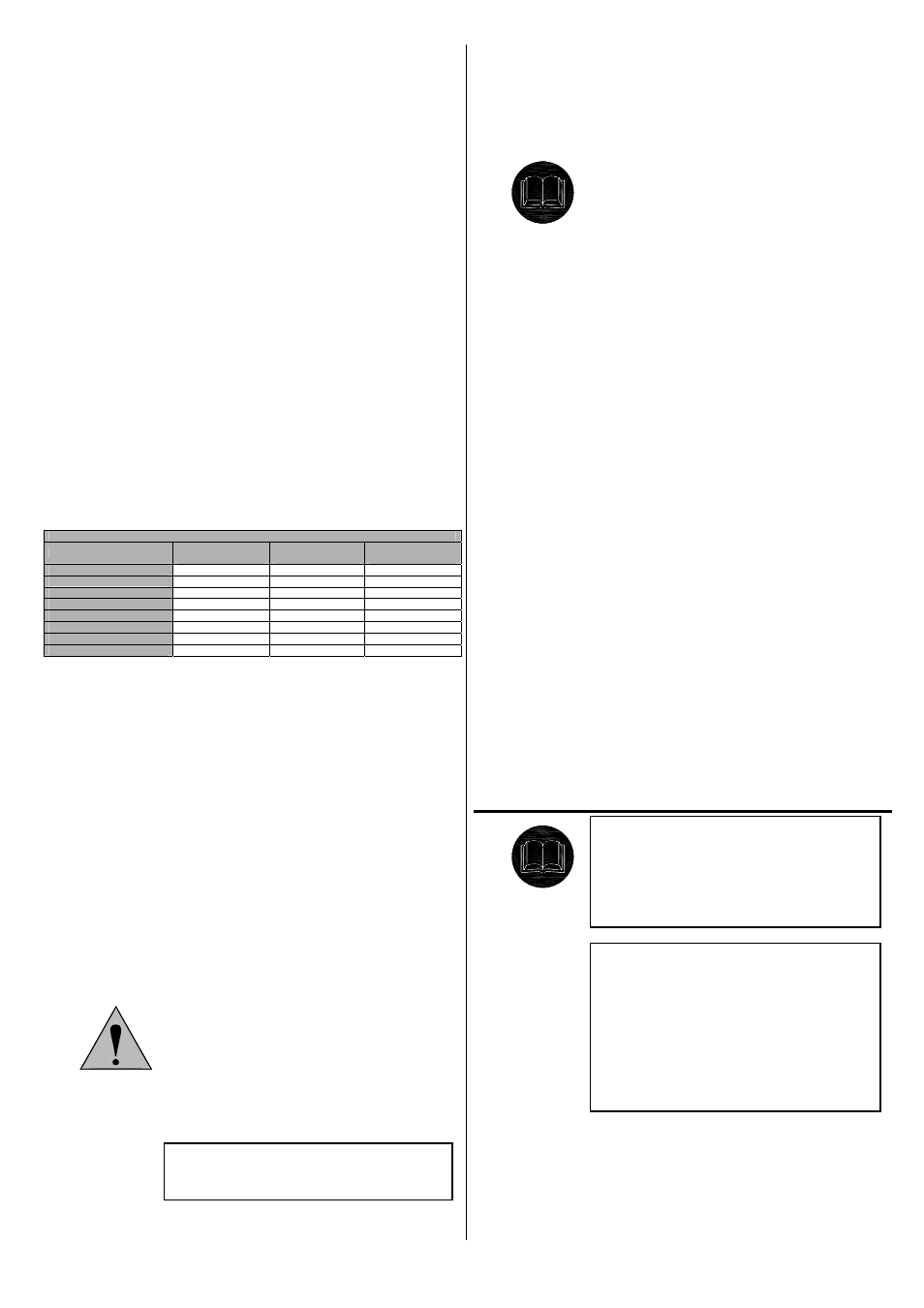

The following table provides oil charge volumes for

blowers:

Oil charge volumes

Oil charge

Type WPB / WVB

Drive side

[l]

Gear side

[l]

Total

[l]

120

0.07 0.1 0.17

300, 400

0.1 0.15 0.25

430, 550, 750

0.2 0.45 0.65

780, 1000, 1300

0.55 0.7 1.25

1600, 2000

0.75 1.4 2.15

3300

1.5 2.75 4.25

4000, 5000

1.4 2.6 4

6500, 7000, 8300

5 6 11

The prescribed oil is fully synthetic motor (automotive)

oil, Rietschle Thomas GEAR LUBE 150:

Use of different oils (e.g., for applications in the food-

processing industry) must be consulted with Rietschle

Thomas.

Electric motor lubrication is described in the enclosed

electric motor manual. There are no other lubrication places

in the blower sets.

The maximum temperature of the oil charges must not

exceed 120 °C (standard stabilization of the blower

bearings).

The maximum revolutions of the pulleys correspond to

those of blowers.

The used designs of the pulley guards or the acoustic

enclosures are tough enough to withstand any damage

(break-off and/or tear) caused by broken belts.

- The speed in the openings for intake and exhaust of air

from the machine hall: between 5 m/s and 10 m/s;

- The recommended speed in the pipeline: 22 m/s;

- The maximum speed in the discharge pipeline: 35 m/s;

and

- The maximum speed in the suction pipeline: 30 m/s.

If the delivery contains no blower discharge pressure

gauge, you must install it on the discharge pipeline. The

used pressure gauge must be glycerine or with an absorber

in order to ensure reliable functioning.

WARNING!

Blowers of standard types are not designed for

use in explosion-hazard environments!

The minimum ambient temperature when the blower set

operation is still stable is -20 °C. Nonetheless, blower sets

can be operated for a short time at a temperature as low as

-30 °C. Such restrictions apply particularly to the belts,

standard types of electric motors, and PVO valves. The

blower set contains no water cooling. The minimum

volume of condensate that builds up in the discharge

pipeline cannot affect the blower set operation.

Wastewater Treatment Plants

- Increasing the volume of oxygen in water and keeping

bacteria above the surface; and

- Ventilating activated

sludge

and detritus tanks in

wastewater treatment plants.

Pneumatic Transport

- Transporting all kinds of loose materials, granules, and

variously-grained materials.

Other Applications

- Backward rinsing of filters in water treatment plants;

- Release of material from silos (storage tanks);

- Clarification of loose materials and mixtures;

- Vacuum

transport;

- Exhaust of air from various equipment systems at an

absolute pressure of up to 500 mbar; and

- Supply of process air at a pressure of up to 1000 mbar.

The standard deliveries of blower sets contain no wiring or

control units. The basic data about the installed electric and

electronic devices are stated on their type plates and in their

accompanying documentation (manuals, connection

diagrams, etc.). The electric part supplier must ensure

conformity with the requirements of the appropriate

standards. The requirements for of equipment with electric

motors, the nominal current of which is below 16 A, were

not verified because the emission of such equipment

depends on the installation and properties of the equipment

complex where the equipment is used. If the delivery

contains a switchboard with a control unit, the unit’s basic

data are stated in separate operating instructions.

A Declaration of Conformity in accordance with the Czech

Republic’s Act No. 22/97 Coll. and the European Union

Council’s Directive No. 98/37/ES is enclosed with this

Manual.

5. O

PERATING THE MACHINE

For at least the guarantee period, you must keep

an operating diary where you record operating

dates, maintenance, inspections, and repairs.

Keeping the operating diary during the guarantee

period is a precondition for accepting guarantee

claims. This applies particularly to the checks

stated in Tables 5 and 6.

Since acoustic enclosures have the same function

as belt drive guards during machine operation,

standard blower sets placed in acoustic enclosures

are not equipped with these guards. Only

authorized persons whose familiarization with the

risk of touching rotating parts can be proved are

allowed to execute operations that are directly

related to putting the blower set into operation,

and those operations that must be performed

when the acoustic enclosure during blower set

operation.

Installation Inspection

- Check the installation of the machine and attachment of

the anchoring bolts;

- Check proper installation of all parts that could be left

unattached during installation. Check especially those parts

that could endanger the operators if they were not attached

and/or installed; and

4.5 U

SE

4.5.1 W

ORK

MEDIA

4.5.2 S

UCTION

AND DISCHARGE

TEMPERATURES

4.5.3 S

UCTION

AND DISCHARGE

PRESSURES

4.5.4 L

UBRICANT

SPECIFICATION

4.5.5

MAXIMUM

TEMPERATURES OF

THE LUBRICATING

SYSTEM

4.5.6 M

AXIMUM

SPEEDS

4.5.7 N

ECESSARY

SAFETY

EQUIPMENT

4.5.6.1

PULLEY

REVOLUTIONS

4.5.6

.2 WORK

MEDIUM SPEED

4.5.8 W

ARNING

AGAINST USE IN

THE EXPLOSION-

HAZARD

ENVIRONMENTS

4.5.9

R

ECOMMENDATIONS

FOR OPERATION AT A

TEMPERATURE OF

0

°C

AND LOWER

4.5.10 A

PPLICATION

FIELDS FOR BLOWERS

AND BLOWER SETS

4.5.11 E

LECTRIC

EQUIPMENT DATA

4.5.12

C

ERTIFICATE OF

CONFORMITY

5.1 I

NSPECTION

PRIOR TO FIRST

TURNING ON THE

BLOWER SET OR

BLOWER