Rietschle thomas gmbh + co. kg page – Elmo Rietschle R-WPB User Manual

Page 13

Rietschle Thomas GmbH + Co. KG

page

13

/

23

L

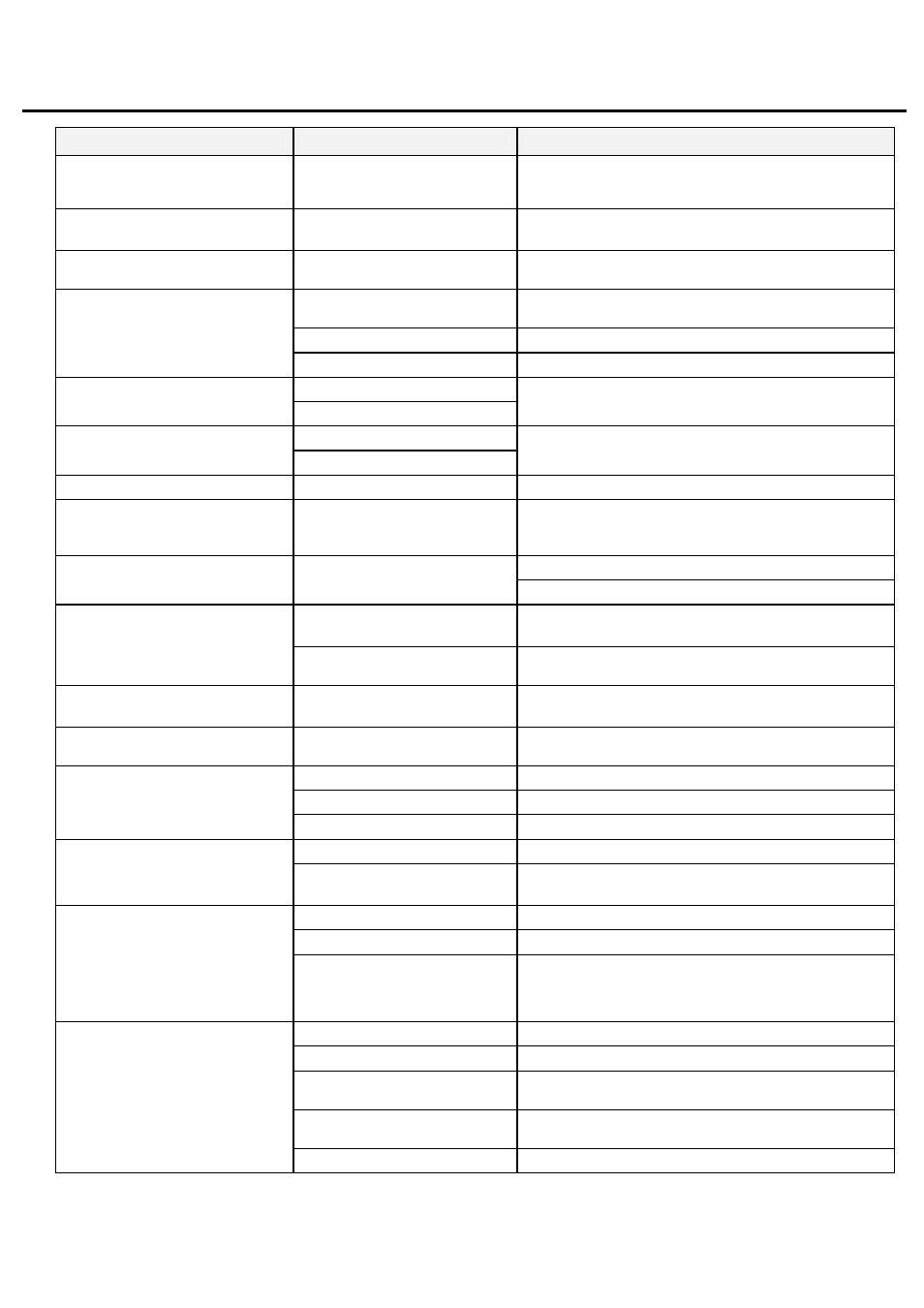

IST OF POSSIBLE FAILURES AND METHODS FOR REMOVING THEM

FAILURE

POSSIBLE CAUSE

REMOVAL

The machine will not start

Electrical part failure

Check the wiring, contactors, fuses, thermal or other protection, and

cable connection state. Check the state and functioning of the electric

motor.

Oil leaks through the ventilation openings

High oil level (measured when the

blower is turned off)

Drain excessive oil.

Elevated noise level, the blower makes a

“metallic” sound

Blower rotor knocking, bearing failure or

incorrect setting of the limit clearances

Repair by the Rietschle Thomas servicemen

Bearing failure or seizing of the rotors in

their working space

Repair by the Rietschle Thomas servicemen

High overpressure in the outlet pipeline

Measure the overpressure and remove the cause.

High current consumption

High vacuum

Replace the filter inserts.

No oil in the blower

High temperature of the cover at the blower

pulley

Bearing failure

Repair by the Rietschle Thomas servicemen

No oil in the blower

High temperature of the cover at the gear

Failure of the bearing or gear

Repair by the Rietschle Thomas servicemen

Slipping belt

Greasy belt

Clean both the belt and the pulleys and degrease them with petrol.

The blower is loaded immediately after

start-up (applies only to blower sets with

PVO valves)

Disengaged starting valve function

Set the combined safety and starting valve so that it will be open when

the machine is turned off.

Check the non-return valve and replace if necessary.

The blower turns spontaneously in the

opposite direction when being turned off

Malfunctioning non-return valve

Disassemble the pipeline and replace the sealing ring.

High overpressure in the outlet pipeline

Measure the overpressure in the outlet pipeline and remove the cause *)

The safety valve is set for maximum + 10% of the outlet overpressure.

The safety valve releases air when the

blower is in operation

Failure of the combined safety and

starting valve

Remove leakage and dirt from the control valve, and/or replace the

rubber bellows.

The safety valve sucks air when the blower

is in operation

High vacuum in the inlet pipeline

Measure the vacuum in the inlet pipeline and remove the cause *)

The safety valve is set for maximum + 10% of the vacuum.

The safety valve will not open when the full

blower load is exceeded

The safety valve is clogged with dirt

(applies to the Herose valves)

Disassemble and clean the valve.

Dirty filter insert

Replace the filter insert.

Overload Maintain

the load - data.

An overheated blower

Large piston clearances

Repair by Rietschle Thomas

Incorrectly installed non-return valve

Repair the installation.

No transport

Slipped or broken belt

Belt failure and/or incorrectly set pulleys

Blower failure

Incorrectly dimensioned blower

Compare the values with the efficiency table.

Leaky safety valve

Check the valve setting and operating pressure.

Low supplied volume

Slipping belt

Check visually the operation of the belt whether it runs without

vibrations. Check the motor power. Recheck the belt state. Set the lower

possible limit of the pendulous motor frame position lower by adjusting

the stop bolt.

The rotors touch each other

Check the bearings and gear setting.

Damaged bearings

Replace the bearings and change oil

Incorrectly aligned pulley and/or

coupling

Adjust it/them and tension the belt of the belt drive.

Loosened bolts securing the motor and/or

blower

Tighten and adjust them.

Vibration

Rotor imbalance due to dirt

Clean the transport space and rotors.

*) The cause might lie in a project error, for example. At a specific flow, the pipeline resistance is higher than the overpressure (required when the blower parameters

were being specified). This is usually detected when the blower is first turned on and/or when the projected machines are being put into operation. Another cause