Rietschle thomas gmbh + co. kg page – Elmo Rietschle R-WPB User Manual

Page 5

Rietschle Thomas GmbH + Co. KG

page

5

/

23

The blower set must be stored in its original packaging in a

dry place and must be protected against dust. Compact

units in the acoustic enclosure intended for outside use can

be stored in the open air. If the blower set has been stored

for more than six months, you should (re)preserve it. For

this purpose, you can use standard preservative agents.

Storage conditions:

Temperature: -30 °C up to 40 °C

Relative humidity: up to 80%

3. I

NSTALLATION AND ASSEMBLY

Assembly in the Open Air

To install the blower set (the set including the enclosure) in

the open air, you must consider the local conditions (snow,

possibility of flooding, etc.)

Service passages and the space necessary for the set

assembly in the machine hall are shown in Appendix 3.

Acoustic enclosures designed for outside use also serve as

weather protection.

Assembly in the machine hall

The minimum dimensions of the machine hall are based on

the maximum dimensions of the compact unit (acoustic

enclosure) and the necessary 1-metre (better 1.2-metre)

operation space at the sides of the blowers (enclosures) and

between the blowers (enclosures). They are further based

on the 1.2-metre space between the wall of the discharge

section at the acoustic enclosure and the wall. The machine

hall height depends on the method chosen for handling the

machine(s).

When designing the machine hall, you must remember the

openings for the blower sets (the delivered sets are

normally assembled). The acoustic enclosure are

demountable. You should consider equipping the machine

hall with an overhead track for a crane crab or leaving

enough space for a forklift truck in order to handle those

blower sets to be maintained or repaired (necessity to

dismantle the blower and/or motor if a failure has

occurred).

The space necessary for installation of individual types of

SHARK blower sets can be derived from the dimensions

stated in the dimensional drawings.

The floor designed for installation must be flat and

dimensioned for the machine weight and anchor length.

With respect to the loading capacity, no special

requirements are stipulated for the floor design since both

the blowers and motors are dynamically balanced. The

mechanical oscillation power of the blowers and motors are

stated in Tables 3 and 4. The weight of the blower set is

distributed between its individual bases. The weight of the

delivered blower set is stated in its appropriate dimensional

drawing.

The blower set must be positioned horizontally by placing

plates under the machine bases. The permitted deviation is

1 mm for 1 metre.

WARNING

After being set in its position, the blower set must

be anchored to the floor. Otherwise, it could move

spontaneously and thus be damaged.

Working procedure for anchoring compact units and

acoustic enclosures.

1. Drill a hole and clean it;

2. Stick the anchor into the hole; and

3. Tighten the nut.

OD

L

OD1

1)

2)

3)

Compact unit –

acoustic enclosure

Anchor

OD [mm] OD1 [mm] L [mm]

WPB/WVB 120 – 430 Upat EXA M 8K

9

8

40

WPB/WVB 550 – 8300 Upat EXA 12/15

13

12

90

K 42 - K 202

Upat EXA M 8K

9

8

40

K 302 - K 802

Upat MC 12/70

13

12

65

The space and diameters of the base holes are stated in the

enclosed dimensional drawing of the compact unit. The

procedure for anchoring acoustic enclosures is the same.

You should, however, pay attention to the tightness of the

gap between the hood and the floor. After setting the hoods

in their positions, you must also level any floor unevenness

in order to prevent the sidewalls from being tight. In order

to seal the gap between the hood and the floor, you can

apply polyurethane foam, for example. The electric cable

must be laid in the floor.

If you intend to put a blower set in the hood on a half grid,

you must order a non-standard enclosure because the

bottoms of the acoustic enclosures are not soundproof.

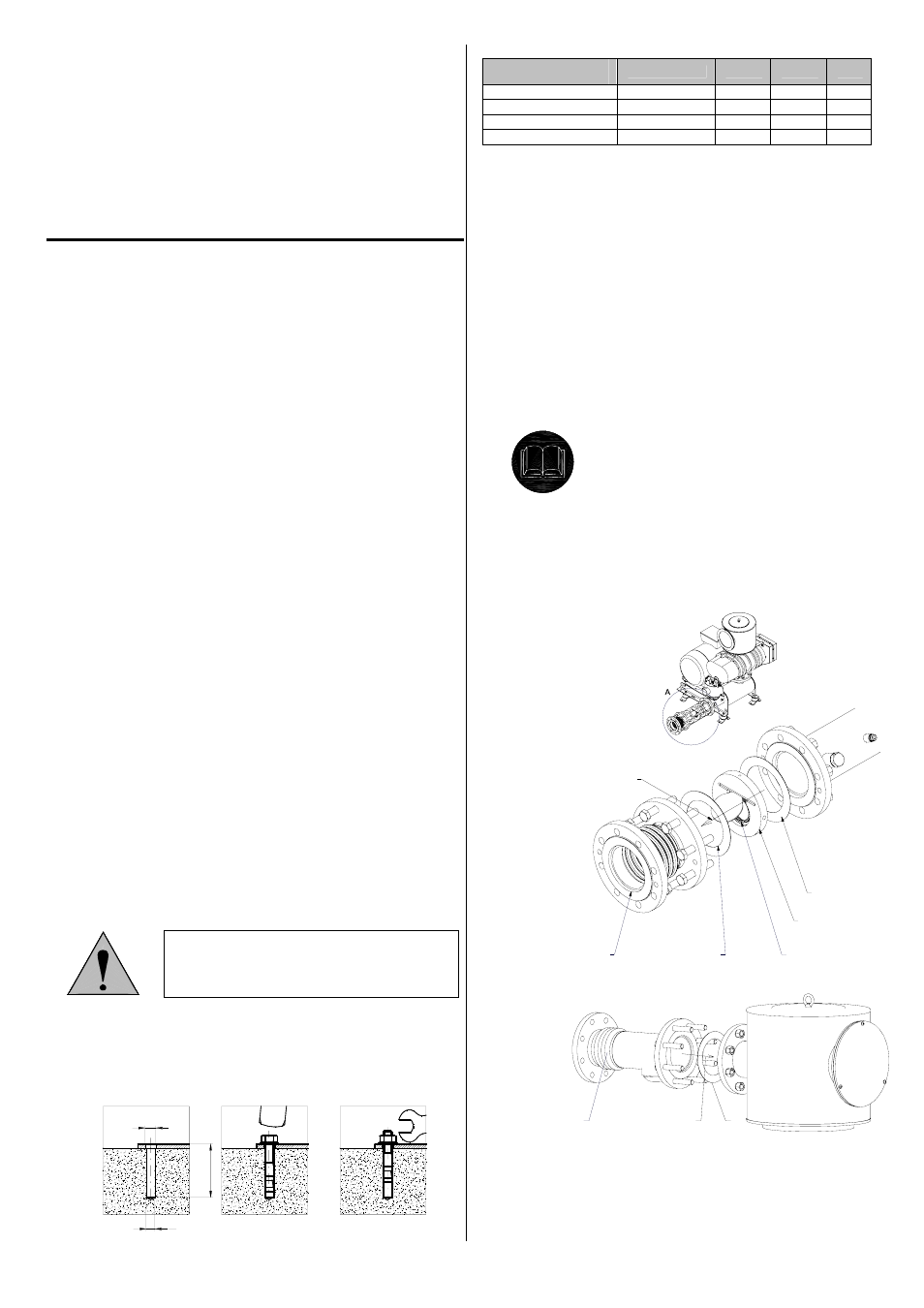

Connecting the pipeline to the SHARK compact unit

Since the entire aggregate is placed on rubber dampers, the

pipeline must be connected through flexible elements.

Otherwise, the running blower could shake the pipeline,

thus increasing the noise level. Standard compact units are

delivered with compensators for connection of the

discharge section. If a SHARK blower for vacuum is been

required or intended to be connected to the central suction,

a compensator for connection of suction is also supplied.

Delivered compensators and valves of larger blower sets

supplied with acoustic enclosures (from the K 302 type) are

not installed. These parts must be installed behind the

outlet flange of the discharge silencer or also in front of the

inlet flange of the suction silencer according to the

following pictures:

Overpressure WPB:

TOP

TOP

4

4

3

1

F

2

Overpressure WPB - central suction:

3

F

4

F Air flow

1. Non-return valve

2. O-ring

3. Compensator

4. Sealing

2.3 S

TORAGE

CONDITIONS

3.1 A

SSEMBLY

CONDITIONS

3.2 S

PACE

NECESSARY FOR

INSTALLATION

AND OPERATION

3.3 R

EQUIREMENTS

FOR ANCHORING THE

BLOWER SET OR

BLOWER

3.4

R

EQUIREMENTS

FOR CONNECTING

THE PIPELINE