Elmo Rietschle S-VSA User Manual

Page 16

- 6 -

4.3 Connections

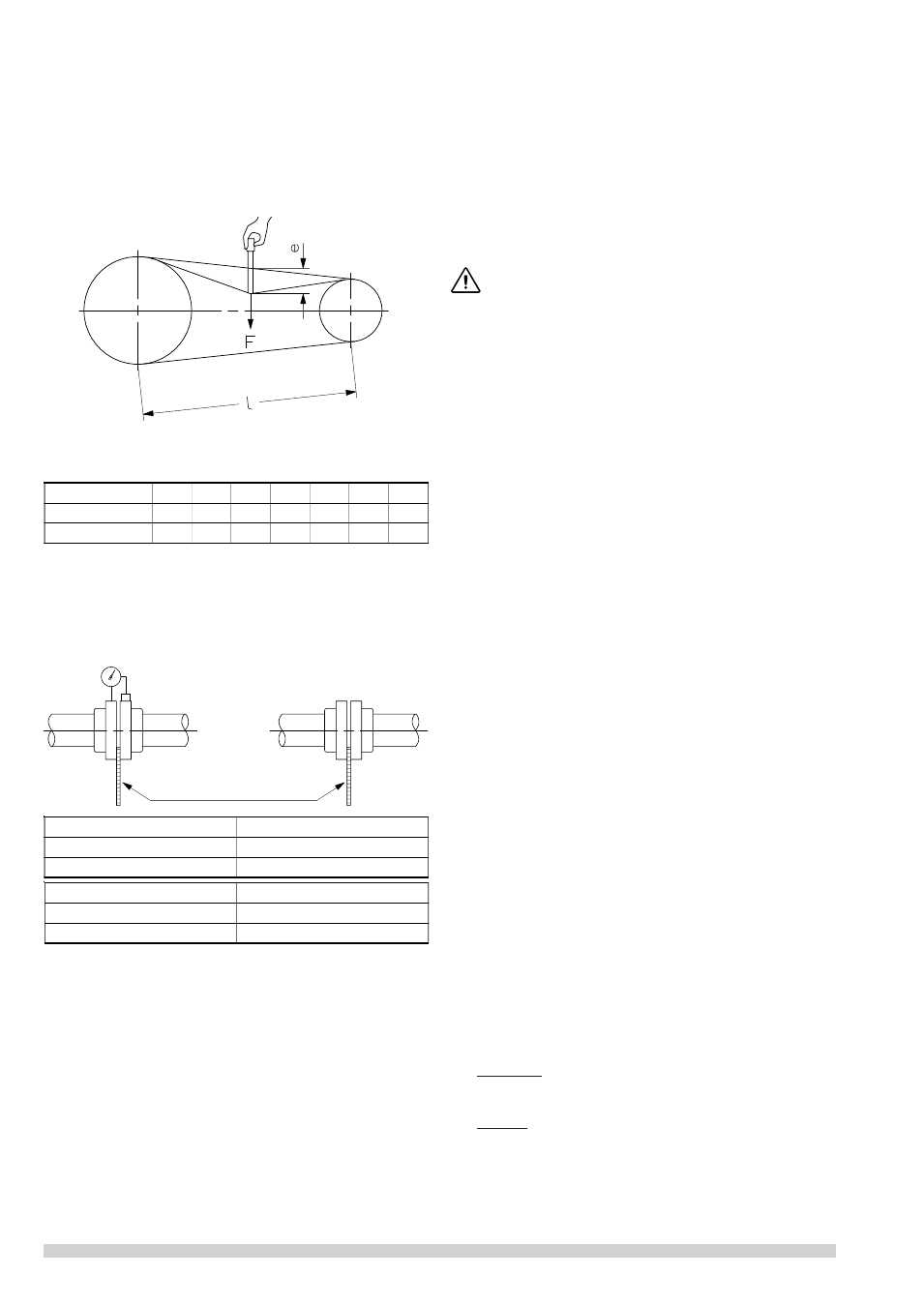

4.3.1 V-belt drive

The lives of belt and bearings greatly depend on the belt ten-

sion. If the belt tension is too loose, reduction of transmission

efficiency due to belt slip, and fatigue and heating of belts will

be considerable, which can make the belt life significantly

shorter and damage bearings as a result of belt vibration.If

belts are too tight, too much tension will be applied and belts

will be weakened and bearing damage may occur. Therefore,

adjust the belt tension properly as shown below.

Type

A

B

C

D

3V

5V

8V

New belt

10

18

39

78

25

77

212

Re-tensioning

13

25

54

98

36

102

271

Apply a below listed load vertically at the centre of “l”.

The deflection at this time is e = 0.016 x l (mm).

Load in belt tension, F (N)

After adjusting, run the pump for few days.. Then re-adjust the

belt tension with the same procedure.

4.3.2 Coupling drive

Align coupling by using Dial Gauge. The concentricity should

be as follows:

Class of motor

On side of coupling

M180

less than 0.05

M200M and above

less than 0.08

Feeler gauge

Motor

Pump

Motor

Pump

side

side

side

side

Class of motor

At end of coupling

M132M and under

less than 0.1

M160M and above

less than 0.18

4.4 Preparation for operation

• Remove dust from Vacuum Pump and piping. Clean the

pipework thoroughly, ensuring welding slag and debris etc.

are removed.

• Check all suction and discharge connections are properly

tightened and all the piping is properly supported. Also

check cooling water piping.

• Supply oil up to the red mark of the oil gauge. If oil level is

low, gear and bearings can seize, and if oil level is too

high, the temperature will rise excessively, and can be the

cause of gear noise or some effect on other parts.

• Cooling water flow to be as specified in chart 1.3.

4.5 First Operation

Warning –> Start-up with pipework

At start-up, severe damage may occur if there is debris in

the pipework.

We therefore recommend a vacuum tight inlet filter of 5

micron rating is installed for start-up.

• With suction valve closed, run the motor briefly to check

direction of rotation, correct if required.

• Run the pump under no load condition for 20-30 minutes

to check for any abnormal vibration or heat. In case of any

abnormality, stop the pump and search for the cause. In

most cases, the cause is improper installation or coupling

centring. Check for correct lubricant level.

• Run the pump for 2 - 3 hours under normal load condition

and check the temperature and vibration of each parts.

• During operation, pay attention to indication of motor am-

pere Meter. If any abnormality is found, stop the pump im-

mediately and check the cause. Often, the cause is inter-

ference between rotors or between the periphery of rotor

and the inner surface of casing. All pumps are factory run

before despatch, however, full care will be still necessary

after the pump installed on site.

* Caution during Operation:

• Check temperature of bearing & lubricant and indication of

Ampere meter & cooling water.

• Keep operation within designated specifications.

4.6 Stopping

• Shut suction valve.

• If any corrosive gas, solvent or water vapour has been

pumped, introduce atmospheric air ( or N

2

) from suction

side for 20-30 minutes before stopping to clean the pump

internals. If a solvent or steam cleaning purge is used, run

the pump for 10 minutes on air or N

2

purge only after steam/

solvent has been turned off.

• Stop the pump by turning off the motor.

• Shut off cooling water. If freezing is anticipated, discharge

water by opening of drain valves.

4.7 Lubrication

Lubricants to be used must be good and high grade petro-

leum products containing oxidation inhibitor, rust preven-

tive, extreme-pressure additive, etc. (Do not use any lubri-

cant which contains any element of water , sulphate resin

or tar.).

Turbine oil (ISO VG 68) readily obtainable in the market

will generally satisfy these requirements.

The following brands are recommended for use as lubri-

cants for gear and bearing.

• Lubricant: BP Energol THHT 68, BP Energol THB 68,

Regal R & O 68, Shell Turbo 68, Mobil Gear 626 or equiva-

lent oils.

• Grease: Aeroshell grease 150, Shell Dorium Grease R, G

40 M, JFE 552 (NOK-Kluber) or equivalent grease.