Installation - section b – Gorman-Rupp Pumps S3B65-E6 460/3 861279 thru 1217130 User Manual

Page 7

S SERIES PUMPS

OM−04151

PAGE B − 1

INSTALLATION

INSTALLATION − SECTION B

GENERAL INFORMATION

Review all SAFETY information in Section A.

Since pump installations are seldom identical, this

section is intended only to summarize general rec-

ommendations and practices required to inspect,

position, and arrange the pump and piping. If there

are any questions concerning your specific instal-

lation, contact your Gorman-Rupp distributor or

the Gorman-Rupp Company.

Liquid level devices are available from Gorman-

Rupp as optional equipment. For information on

installing and operating these items, refer to the lit-

erature accompanying them.

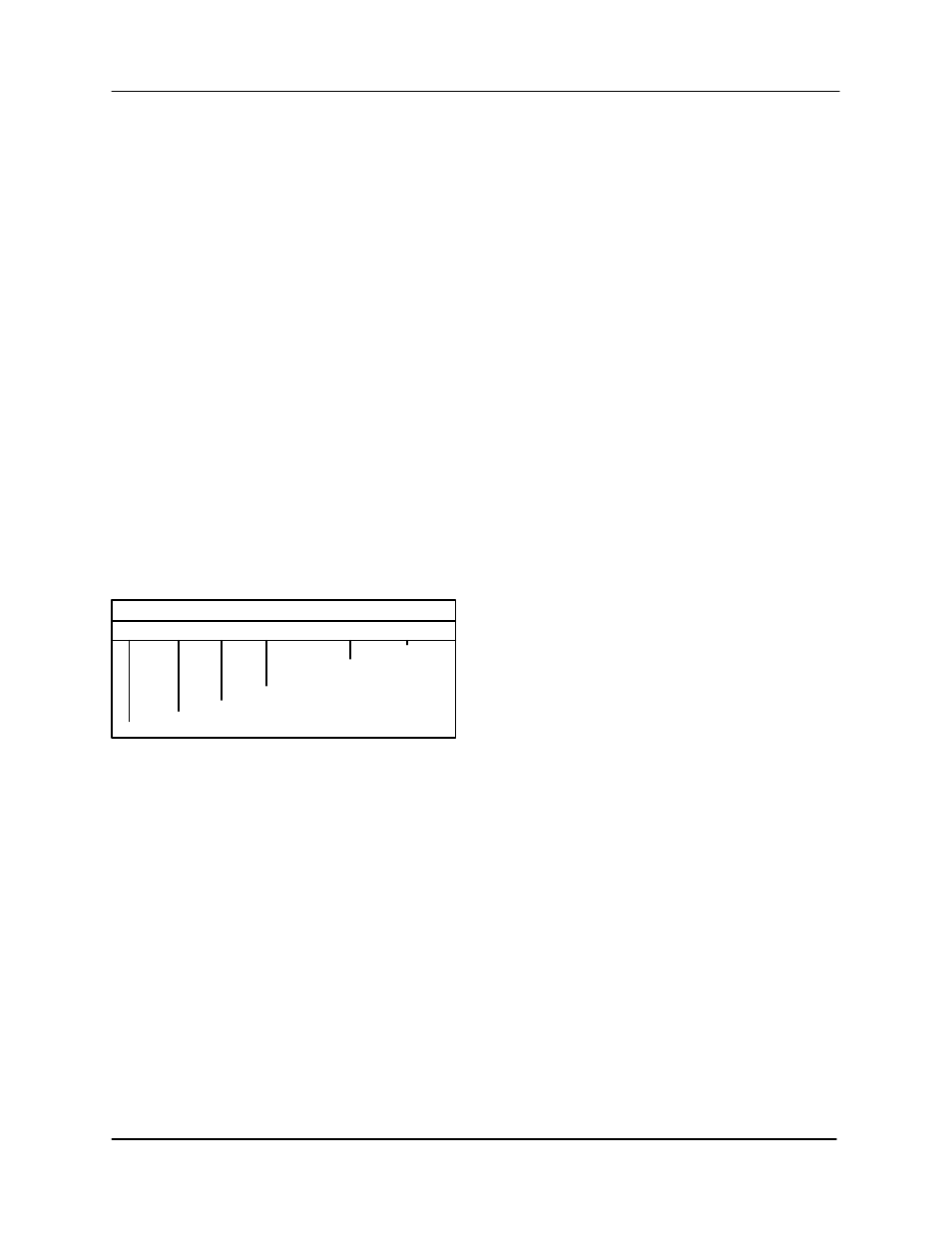

Pump Model Designation

Following is a description of the model numbering

system for S Series pumps. These submersible

pumps are available in a range of sizes. Refer to the

following chart to identify the size for your specific

pump model.

S

Series

Discharge Size

Pump Hydraulics

Pump Construction

H.P. (If Shown)

Voltage/Phase

3

C

1

E

230/3

−

6.2

Pump Model

PREINSTALLATION INSPECTION

The pump assembly was inspected and tested be-

fore shipment from the factory. Before installation,

check for damage which may have occurred dur-

ing shipment. Check as follows:

a. Inspect the pump assembly for cracks, dents,

damaged threads, and other obvious dam-

age.

b. Check for loose attaching hardware. Since

gaskets tend to shrink after drying, check for

loose hardware at the mating surfaces.

c. Inspect the power cable for cuts or any other

obvious damage.

d. Check that amperes, phase, voltage and

hertz indicated on the name plate match the

ratings on the control box and incoming pow-

er.

e. Carefully read all tags, decals, and markings

on the pump, and perform all duties indicated.

f. Check for oil leaks. If there is any indication of

an oil leak, see LUBRICATION at the end of

this manual.

PUMP SEAL

S Series pumps utilize one of the following sealing

methods.

1. There are two shaft seals in the pump. The

lower seal prevents liquid from entering the in-

termediate cavity at the impeller end. The up-

per seal prevents oil leakage from the motor

housing cavity and acts as back-up protection

in the event of lower seal failure.

2. The pump is equipped with one double-faced

seal assembly. It is designed to prevent the

liquid being pumped from entering the inter-

mediate cavity at the impeller end, and to pre-

vent moisture from entering the motor hous-

ing cavity at the motor end.

Regardless of which sealing method is used, the

seal is lubricated by premium quality submersible

pump oil.

LUBRICATION

S series pumps are lubricated in one of the follow-

ing methods.

1. Some pumps utilize two lubrication cavities.

The motor housing cavity provides lubrication

to the motor assembly and bearings, while the

intermediate cavity provides lubrication to the

pump seal.

2. Some pumps utilize one lubrication cavity, lo-

cated just behind the seal plate. It is filled with

premium quality submersible pump oil which

lubricates the pump seal. The motor operates

in and is cooled by air, therefore it requires no

lubrication.

All S Series pumps are fully lubricated when

shipped from the factory. However, lubrication lev-

els must be checked before installing the pump

- S3B65-E6 575/3 1199517 and up S3C1 230V 3P 861279 thru 1207589 S3C1 460V 3P 861279 thru 1207589 S3C18 230V 3P 861279 thru 1217140 S3C18 460V 3P 861279 thru 1217140 S4C65-E10 460/3 861279 thru 1142084 S4D65-E10 460/3 861279 thru 1141092 S2F1-E1 230/3 997771 thru 1225728 S2F1-E1 460/3 997771 thru 1225728