Gorman-Rupp Pumps S3B65-E6 460/3 861279 thru 1217130 User Manual

Page 29

S SERIES PUMPS

OM−04151

PAGE C − 3

OPERATION

The electrical power used to operate

this pump is high enough to cause inju-

ry or death. Make certain that incoming

power is off and locked out before inter-

changing motor leads.

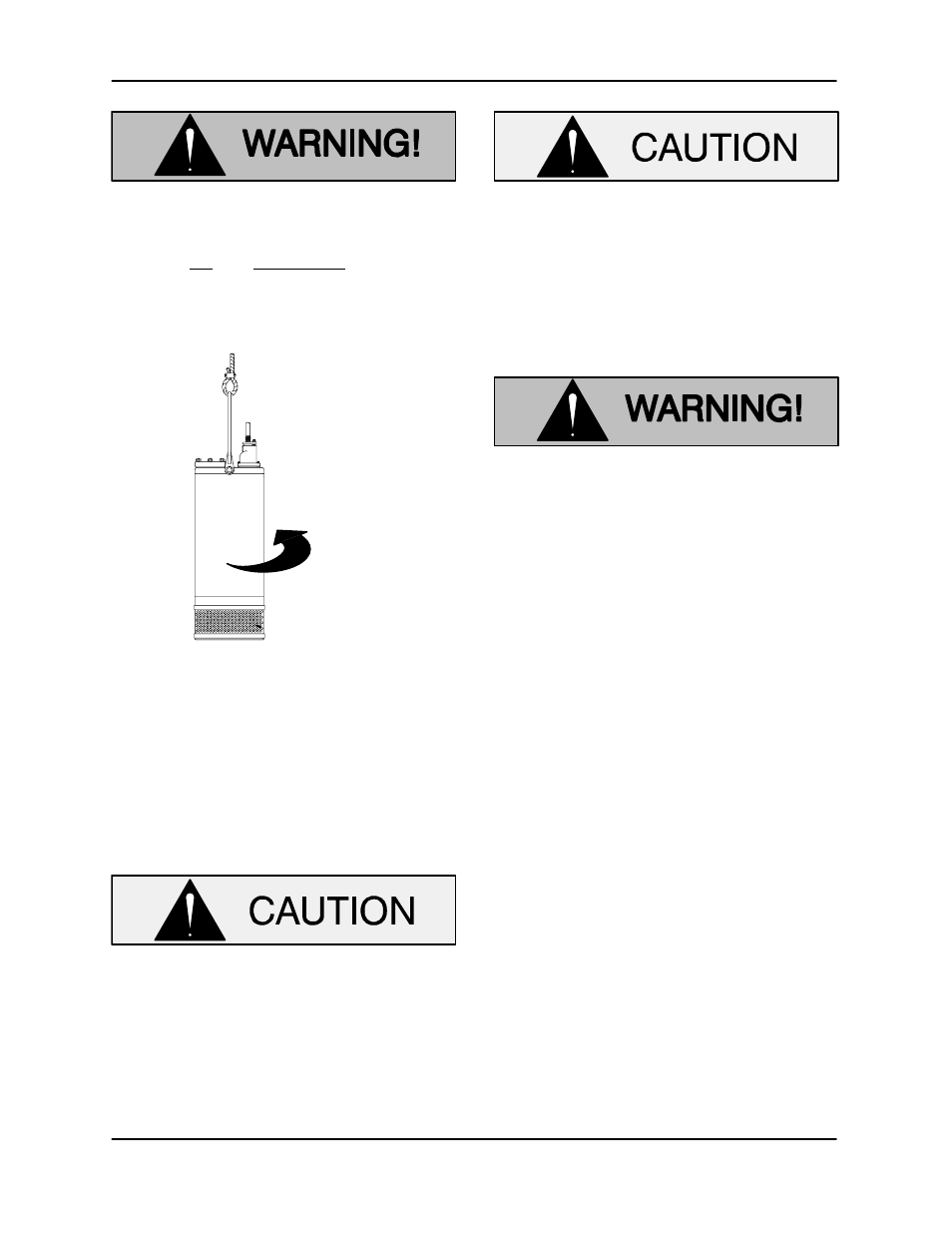

DIRECTION OF

KICKBACK

AT STARTUP

Figure C−1. Checking Pump Rotation

STARTING, STOPPING, AND

OPERATIONAL CHECKS

Starting

Do not attempt to operate the pump until

impeller rotation has been checked; im-

proper rotation will affect pump perform-

ance and may damage the pump.

Follow the instructions accompanying the control

box, start the pump, and run any recommended

checks.

Never start the pump more than 6 times per

hour. If the pump motor does not cool be-

tween starts, it will over-heat, resulting in

damage to the motor windings.

Stopping

Follow the instructions accompanying the control

box for stopping the pump.

On pumps equipped with a motor ther-

mal protector, the integral thermal over-

load device will shut off the motor if the

temperature rises above design limits.

When the pump cools and the tempera-

ture falls below these limits, the motor

will restart automatically. To avoid the

hazards of an unexpected motor start-

up, do not attempt to handle or service

the pump unless all power to the motor

has been shut off and locked out at the

control box; otherwise, serious person-

al injury could result.

During motor shutoff by the thermal

overload device, control box circuits re-

main live. Do not attempt to service any

control box components unless incom-

ing power has been shut off.

To stop the pump, turn the control handle OFF,

thereby opening the circuit breakers. This does

not terminate incoming power through the field

wiring connected to the control box.

After stopping the pump, be sure to perform all re-

quired maintenance and preservation procedures.

Operational Checks

To detect minor problems, check the pump for

proper operation when it is first started, and at peri-

odic intervals during operation.

- S3B65-E6 575/3 1199517 and up S3C1 230V 3P 861279 thru 1207589 S3C1 460V 3P 861279 thru 1207589 S3C18 230V 3P 861279 thru 1217140 S3C18 460V 3P 861279 thru 1217140 S4C65-E10 460/3 861279 thru 1142084 S4D65-E10 460/3 861279 thru 1141092 S2F1-E1 230/3 997771 thru 1225728 S2F1-E1 460/3 997771 thru 1225728