Gorman-Rupp Pumps S3B65-E6 460/3 861279 thru 1217130 User Manual

Page 19

S SERIES PUMPS

OM−04151

PAGE B − 13

INSTALLATION

cal connections. Make certain that the

pump and enclosure are properly

grounded; never use gas pipe as an

electrical ground. Be sure that the in-

coming power matches the voltage and

phase of the pump and control before

connecting the power source. Do not

run the pump if the voltage is not within

the limits.

Do not connect the pump motor directly

to the incoming power lines. The pump

motor is designed to operate through a

Gorman-Rupp approved control box

which provides overload protection and

power control; otherwise, the pump

warranty will be voided. Make certain

that the pump and control box are prop-

erly grounded. Install and operate the

control box in accordance with the Na-

tional Electric Code and all local codes.

Failure to follow these could result in in-

jury or death to personnel.

Field wiring is not provided with the pump, and

must be supplied by the user. The field wiring must

be of the proper size and type to ensure an ade-

quate voltage supply to the pump. Voltage avail-

able at the motor must be within the range indi-

cated in Table B-3.

To calculate the voltage available at the motor, pro-

ceed as follows:

a. Measure the voltage across the incoming

lines (1 & 2 for single phase, 1 & 2, 2 & 3, and 1

& 3 for three phase) while the pump is oper-

ating at full capacity. Refer to the literature

supplied with the control box for power supply

connections.

b. Next, subtract the motor cable voltage drop

(see Table 4, Pump Power Cable Specifica-

tions).

c. Do not continue to operate the pump if this

voltage is not within the recommended limits.

Obtain the services of a qualified electrician to

determine the correct field wiring size and oth-

er details to ensure an adequate voltage sup-

ply to the pump.

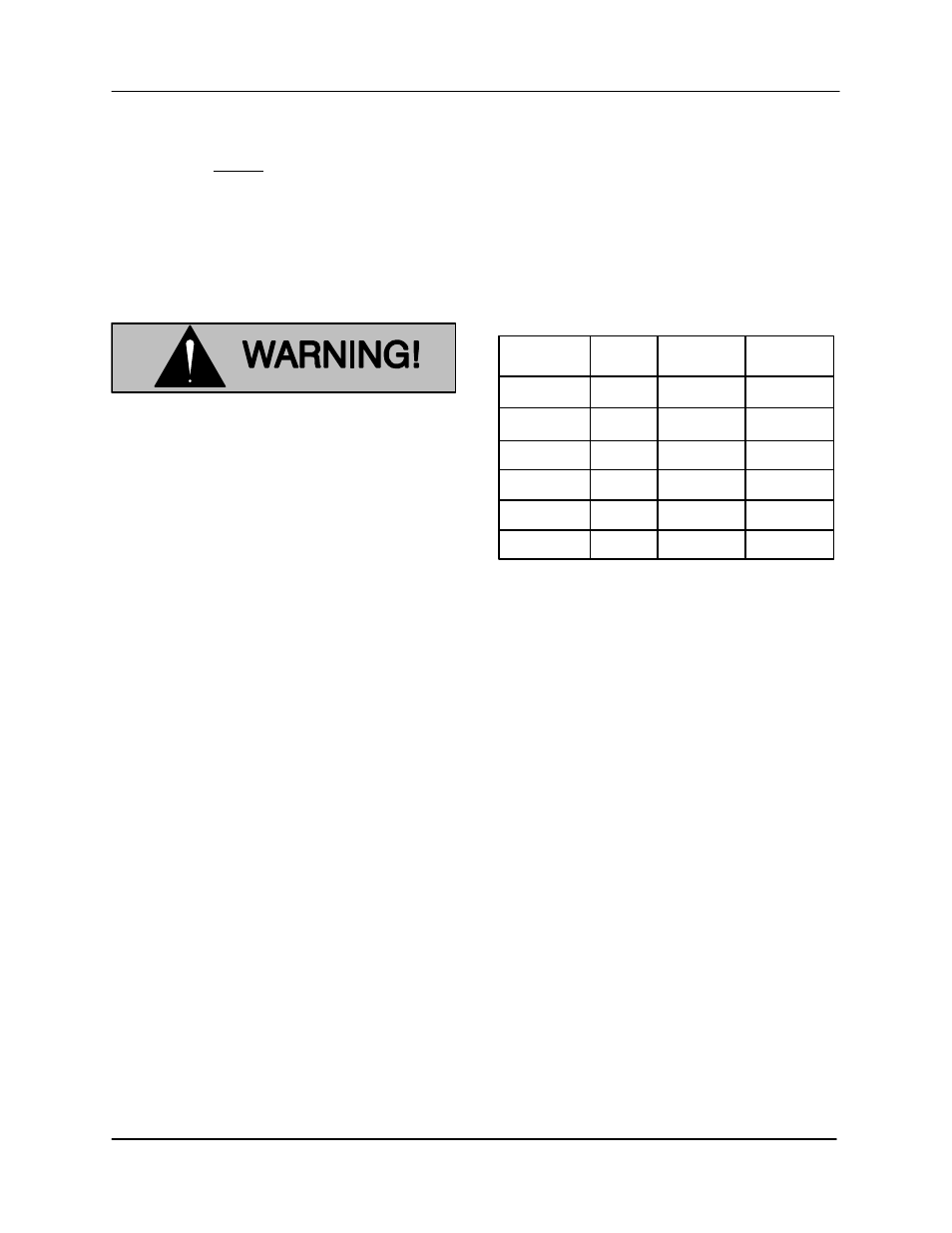

Table B-3. Pump Voltage Requirements

NOMINAL

VOLTAGE

3

3

230

460

210

420

250

500

PHASE

MINIMUM

VOLTAGE

MAXIMUM

VOLTAGE

1

230

220

240

575

3

520

630

1

115

110

120

380

3

345

415

Make certain all connections are tight and that

cable entry points are rainproof. Support the cable

weight, if required, to prevent excessive strain on

cable clamps and cable.

Grounding Methods

Electrically ground the installation before connect-

ing the field wiring to the control box. Install a

grounding terminal to the enclosure and connect

it to a properly embedded electrode.

The material used for the electrode must be an ex-

cellent conductor of electricity, such as copper. If

iron or steel is used, it must be galvanized or other-

wise metal plated to resist corrosion. Do not coat

the electrode with any material of poor conductiv-

ity, such as paint or plastic.

The electrode must conform to the recommenda-

tions of N.E.C. ARTICLE 250. Follow all installation

requirements of the N.E.C., and all applicable

codes. See Figure B−3 for some suggested

grounding methods.

- S3B65-E6 575/3 1199517 and up S3C1 230V 3P 861279 thru 1207589 S3C1 460V 3P 861279 thru 1207589 S3C18 230V 3P 861279 thru 1217140 S3C18 460V 3P 861279 thru 1217140 S4C65-E10 460/3 861279 thru 1142084 S4D65-E10 460/3 861279 thru 1141092 S2F1-E1 230/3 997771 thru 1225728 S2F1-E1 460/3 997771 thru 1225728