Installation - section b – Gorman-Rupp Pumps 810A2-4045T 1529947 and up User Manual

Page 8

OM-06543

80 SERIES

PAGE B - 1

INSTALLATION

INSTALLATION - SECTION B

Review all Safety information in Section A.

Since pump installations are seldom identical, this

section offers only general recommendations and

practices required to inspect, position, and ar

range the pump and piping.

Most of the information pertains to a standard

static lift application where the pump is positioned

above the free level of liquid to be pumped.

If installed in a flooded suction application where

the liquid is supplied to the pump under pressure,

some of the information such as mounting, line

configuration, and priming must be tailored to the

specific application. Since the pressure supplied

to the pump is critical to performance and safety,

be sure to limit the incoming pressure to 50% of the

maximum permissible operating pressure as

shown on the pump performance curve. (See Sec

tion E, Page 1.) If the pump is fitted with a Gorman‐

Rupp double grease lubricated seal, the maximum

incoming pressure must be reduced to 10 p.s.i.

For further assistance, contact your Gorman‐Rupp

distributor or the Gorman‐Rupp Company.

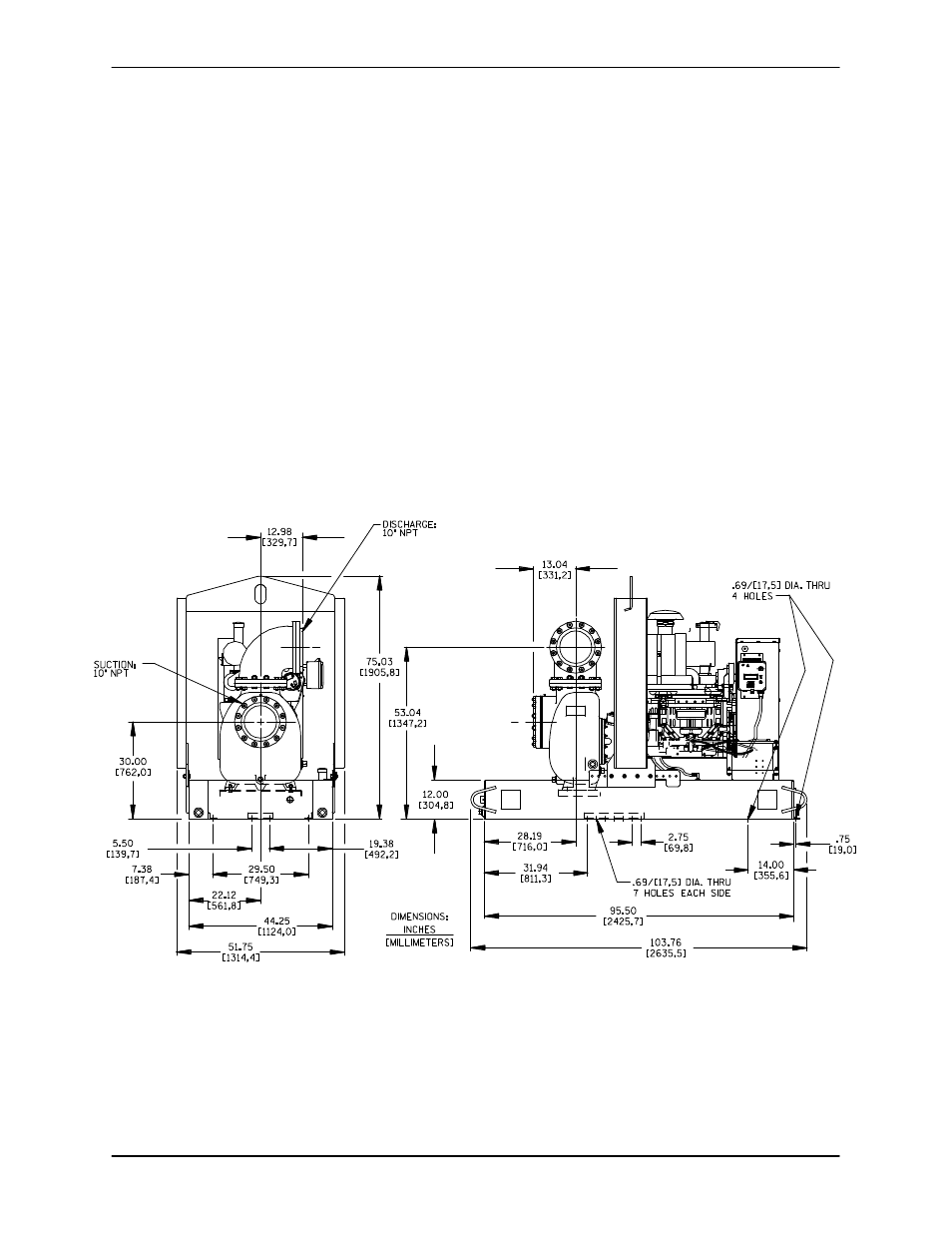

Pump Dimensions

See Figure 1

for the approximate physical dimen

sions of this pump

.

OUTLINE DRAWING

Figure 1. Pump Model 810A2‐4045T

PREINSTALLATION INSPECTION

The pump assembly was inspected and tested be

fore shipment from the factory. Before installation,

inspect the pump for damage which may have oc

curred during shipment. Check as follows:

a. Inspect the pump for cracks, dents, damaged

threads, and other obvious damage.

b. Check for and tighten loose attaching hard

ware. Since gaskets tend to shrink after dry

ing, check for loose hardware at mating sur

faces.