Gorman-Rupp Pumps 06C1-GAR 1289163 and up User Manual

Page 12

OM--05688

0 SERIES

PAGE B -- 6

INSTALLATION

suction line to ensure an adequate supply of liquid

to the pump.

Damage to the pump resulting from debris

in the suction line

will not be covered by

the pump warranty.

Before connecting the suction and dis-

charge piping, carefully check the storage

tank and piping for construction debris

such as nuts, bolts, wire, weld slag, and

other foreign material. Install a commer-

cially available 80 mesh screen in the suc-

tion line to prevent debris from entering the

pump.

If a throttling valve is desired in the discharge line,

use a valve as large as the largest pipe to minimize

friction losses. Never install a throttling valve in a

suction line.

With high discharge heads, it is recommended that

a throttling valve and a system check valve be in-

stalled in the discharge line to protect the pump

from excessive shock pressure and reverse rota-

tion when it is stopped.

Sealing

Since even a slight leak will affect priming, head,

and capacity, especially when operating with a

high suction lift, all connections in the suction line

should be sealed with pipe dope to ensure an air-

tight seal. Follow the sealant manufacturer’s rec-

ommendations when selecting and applying the

pie dope.

Valves

Gorman-Rupp manufactures several sizes of flow-

diverting (FDF) valves for use in truck-mounted

pumping applications. The valves are designed to

reverse the flow of liquid with only the turn of a han-

dle. This allows the same pump to fill or dispense

from the tank.

The FDF valve is designed for directing

flow only. it will not serve as a positive shut-

off or throttling valve.

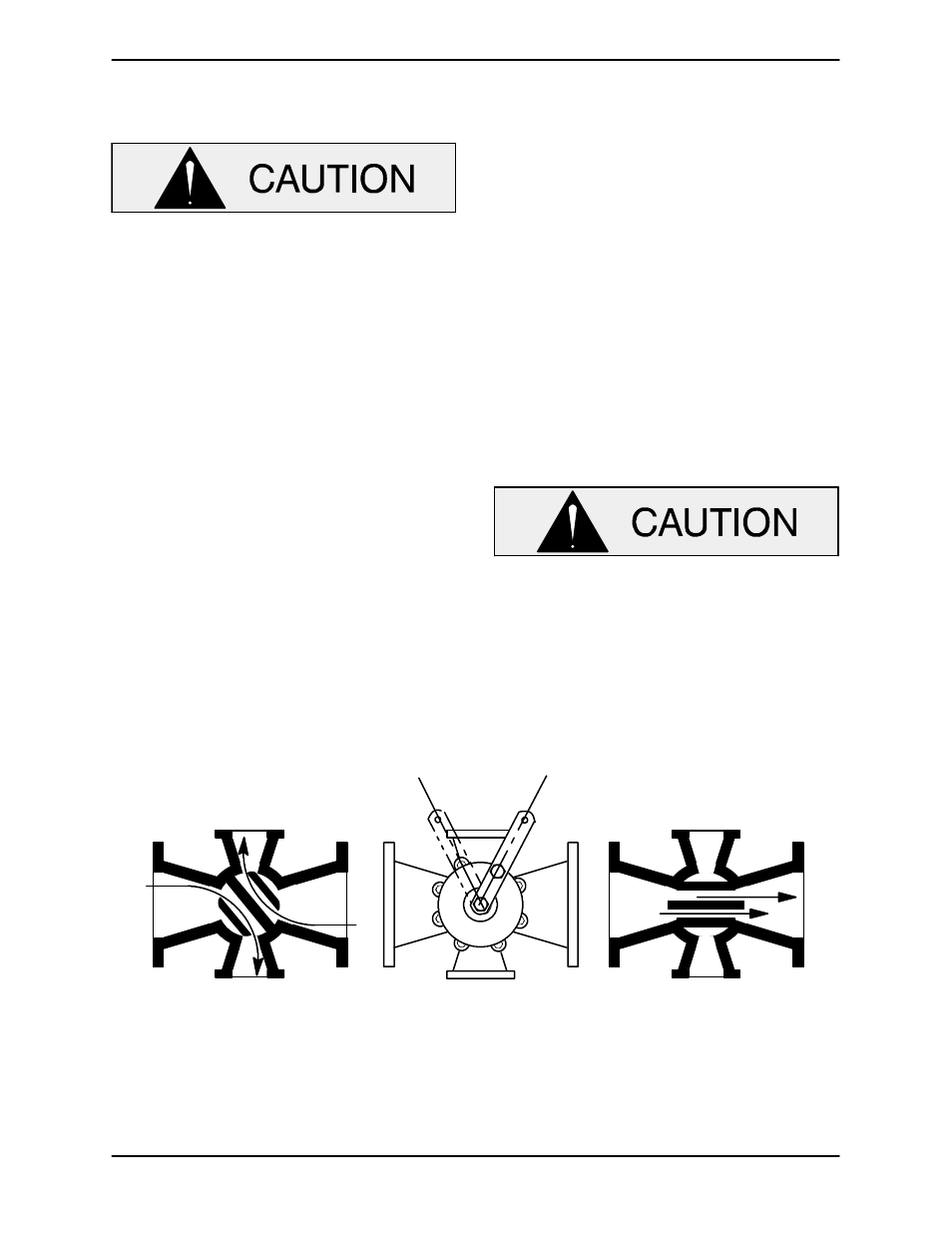

See Figure 5 illustrating the theory of operation for

a typical FDF valve. Consult the factory for further

assistance or other sizes.

FILL

POSITION

DISPENSE

FILL

TOP VIEW

DISPENSING

POSITION

Figure 5. FDF Valve Theory of Operation

When the center web of the valve is aligned with the

larger ports (filling position), the flow passes

straight through. When the handle is turned to the

dispensing position, the web blocks the straight

flow and opens two paths of flow through the larger

ports to the smaller ports.