Extron Electronics WMK 100 User Manual

Preliminar y, Installation, Mount the base plate

PRELIMINAR

Y

1

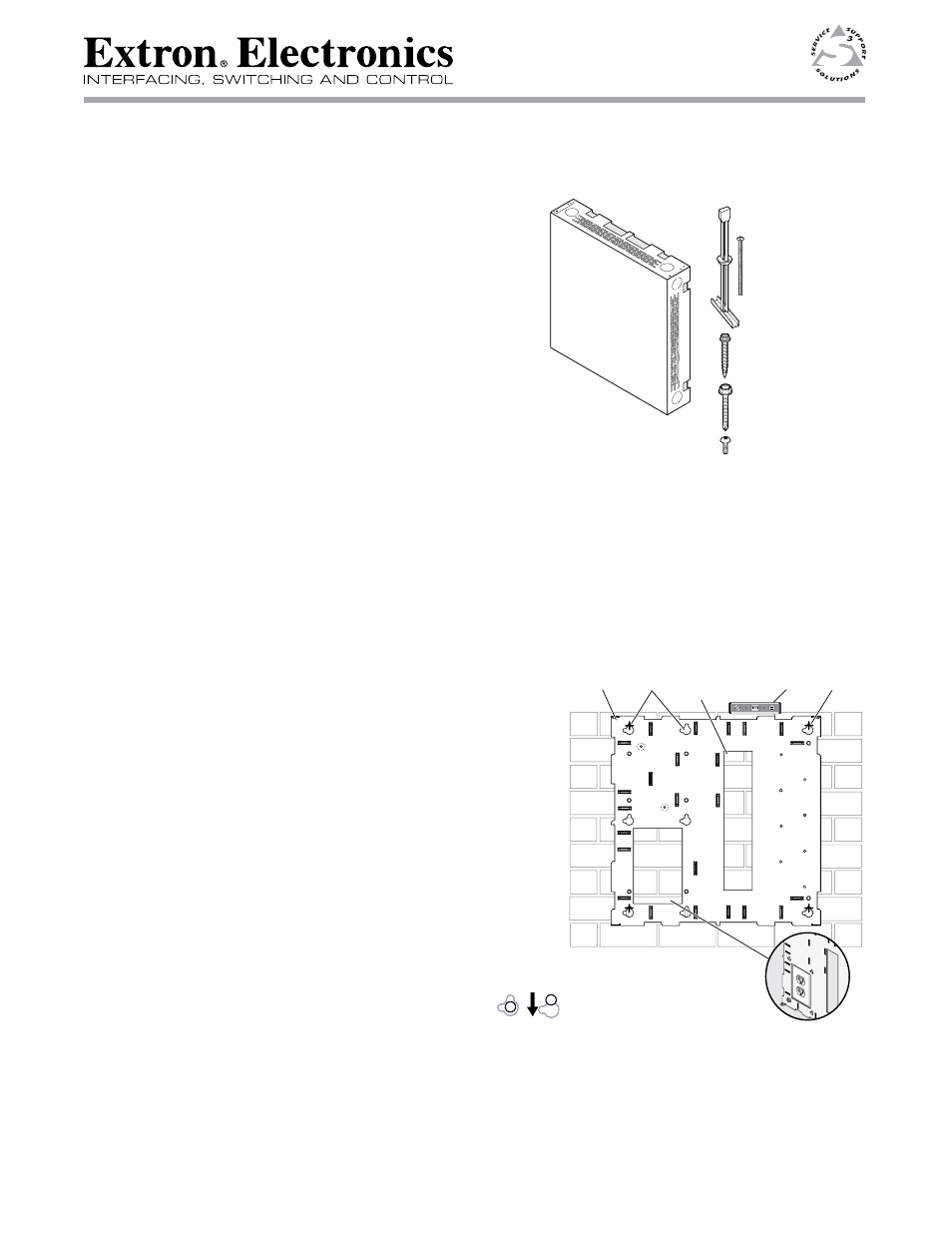

The Extron WMK 100 Wall Mounting Kit is used for hanging PoleVault

®

System A/V products on a wall near

a flat screen display or short throw projector.

The WMK 100 has a 13" x 13" x 2.5" deep enclosure to mount the

PoleVault switcher and the power supply, with room for cable

management. It also has knockouts on all four sides which allow

external raceways to be used where necessary for cabling.

C

Maximum load for the WMK 100 is 15 lbs (7 kg)

.

The key components (base plate and cover) of the WMK 100 are

shown in figure 1.

Included in the kit are:

(4) ¼-20 x 2" pan head bolts, (4) ¼" Kap toggle assemblies,

(4) ¼ x 1¾" masonry screws, (4) #14 x 1¾" self tapping metal/wood

screws, (4) 6-32 x ¼" button head hex screws.

Not shown but included are (3) 4-40 x ¼" screws, (2) hook-and-loop

straps.

Installation

N

Refer to local building standards and codes to verify that the installation will meet the regulatory

requirements. Observe all local and national building and safety codes, UL requirements, and ADA

accessibility guidelines.

Before installation identify the type of wall (masonry or non-masonry) and the location where the WMK 100 will be

installed. This determines the installation approach and the type of fasteners needed to secure the plate to the wall.

1. Mount the base plate

Follow the steps within 1A or 1B below, as applicable.

N

The base plate can be installed over an existing electrical

outlet. The opening fits standard sized 2.75" x 4.5" wall

plates. See figure 2 (inset).

1A. To mount the WMK 100 onto masonry walls:

i.

Hold the base against the wall, level it, and mark the

positions of four slotted mounting holes (indicated by

+ marks in figure 2). Set the plate aside.

N

Use the top slot position at each mounting hole. Do not use

both top and left slots as this will make it difficult to slide the

plate down (see step iv).

ii.

Using a masonry drill bit, drill 1.75" (4.4 cm) deep pilot holes

at the marked locations.

iii.

Screw in masonry screws until a gap of 1/8" to 3/8"

(3 to 9 mm) remains between the wall and the screw heads.

iv.

Align the base plate's slotted mounting holes over

the installed screws, then slide the plate down so

the screws fit into the slots.

v.

At this time, lightly tighten all the screws to secure the plate

to the wall and verify level and position.

N

Do not over tighten, as the plate needs to be removed to attach the

switcher and power supply before cabling.

Proceed to Step 2.

The plate can be aligned over an existing electrical outlet.

WMK 100 Installation Notes

Figure 1 — WMK 100 parts

68-1738-01

Rev A

06 09

Figure 2 — Masonry wall mounting

(4) 1/4" x 1 3/4" Masonry Screws

#40-373-01

(4) #14 x 1 3/4" Self-tapping

Metal/Wood Screws

#40-372-01

(4) 1/4-20 x 2"

Pan Head Bolts

#40-375-01

(4) 1/4" Kap Toggle Assemblies

#40-374-01

(4) 6/32" x 1/4" Button Head

Hex Screws

#40-363-17LF

+

+

Cutout for

Electrical

Outlet

Level

Cutout for

Signal Cable

Access

Marker for

Pilot Hole

WMK 100

Base Plate

Mounting

Holes