Wmk 160 • installation guide (continued), Installation, Step 1 – Extron Electronics WMK 160 User Manual

Page 2: Mount the base plate

2

WMK 160 • Installation Guide (Continued)

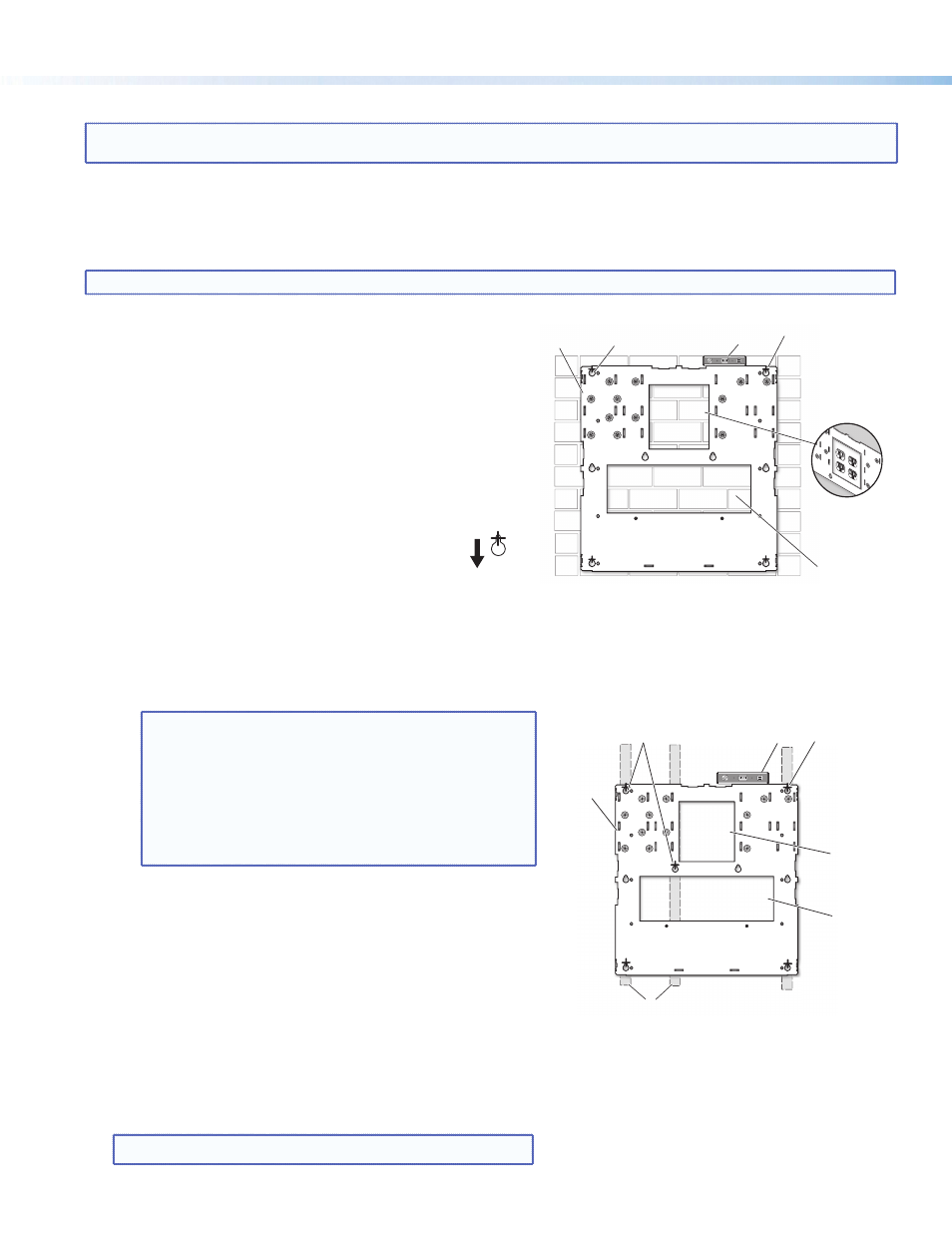

Figure 3.

Non-masonry wall mounting

Wall Studs

Cutout for

Electrical

Outlet

Level

Marker for

Pilot Hole

Cutout for

Signal Cable

Access

Mounting

Holes

WMK 160

Base Plate

Installation

NOTE: Refer to local building standards and codes to verify that the installation will meet the regulatory requirements.

Observe all local and national building and safety codes, UL requirements, and ADA accessibility guidelines.

Before installation identify the type of wall (masonry or non-masonry) and the location where the WMK 160 will be installed.

This determines the installation approach and type of fasteners needed to secure the plate to the wall.

Step 1.

—

Mount the Base Plate

Follow the steps within

1A or 1B, as applicable.

NOTE:

The base plate can be installed over an existing electrical outlet (see figure 2).

1A. To mount the WMK 160 onto masonry walls:

i.

Hold the base against the wall, level it, and mark the

positions of four slotted mounting holes (indicated by

+ marks in figure 2). Set the plate aside.

ii.

Using a masonry drill bit, drill 1¾ inch (4.4 cm) deep

pilot holes at the marked locations.

iii.

Screw in ¼ x 1¾ inch masonry screws (not supplied)

until a gap of about 3/8 inch (9 mm) remains between

the wall and the screw heads.

iv.

Align the slotted mounting holes of the base plate

over the installed screws, then slide the plate

down so the screws fit into the slots.

v.

Verify level and position and tighten all the screws to secure

the plate flush to the wall.

Proceed to step 2.

1B. To mount the WMK 160 onto a non-masonry wall:

i.

At the desired site, locate and mark the wall studs.

NOTES:

•

For ideal installation secure the base plate to at least

one wall stud (see figure 3). Drywall KapToggles can be

used for holes not aligned with studs.

•

Always use the widest spacing of screws and

KapToggles.

•

The base plate can be installed over an existing

electrical outlet (see figure 2).

ii.

Hold and level the base plate against the wall and mark

the positions of the slotted mounting holes that are on

the stud lines (see figure 3, indicated by + marks). Where

applicable, mark the mounting holes on the wall for

drywall toggles.

iii

. If the cables are to be run behind the wall to the

WMK 160 location, mark the cutout area on the wall for

the signal cable access hole (see figure 3). Remove the base

plate and set the plate aside.

iv.

Drill 1¾ inch (4.4 cm) deep pilot holes at the hole marks.

v.

Cut out the marked area for cable access.

vi.

At the pilot holes, screw in the screws until a gap of about

3/8 inch (9 mm) remains between the wall and the screw heads.

NOTE:

If using toggle assemblies, see figure 4 for method.

Cutout for

Electical

Outlet

Level

Cutout for

Signal Cable

Access

Marker for

Pilot Hole

WMK 160

Base Plate

Mounting

Holes

Figure 2.

Masonry wall mounting