Air supply, Mechanical power venting option, Important standing pilot instructions – John Wood Commercial - ANED User Manual

Page 12: Installation check list

Page11

AIR SUPPLY

Ensure that adequate ventilation is available to supply

make-up air for proper combustion. Openings sufficient to

provide one square inch of free area for each 1,000 BTU/hr.

input rating of all appliances must be provided for this

purpose. Where heaters are installed in a confined space,

two openings - one near the top of the enclosure and one

near the bottom each having a free area of one square inch

for each 1,000 BTU/hr. input - shall be provided. Refer to

standard CAN 1-B.149-1 or .2 or local codes for complete

ventilation and combustion air requirements.

If an exhaust fan is in the same room as a heater, adequate

air openings must be provided in the walls, otherwise, air

may be drawn into the room through the chimney or flue

causing poor combustion.

MECHANICAL POWER VENTING OPTION

Power venting is an option on your water heater. A power

venter kit is available for every model. Please consult with

the company for more details.

FOR YOUR SAFETY

READ BEFORE LIGHTING

IMPORTANT

STANDING PILOT INSTRUCTIONS

A. This appliance has a pilot which must be lighted by hand.

When lighting the pilot, follow these instructions exactly.

B. BEFORE LIGHTING smell all around the appliance area

for gas. Be sure to smell next to the floor because some

gas is heavier than air and will settle to the floor.

What To Do if You Smell Gas

-

Do not try to light any appliance.

-

If you cannot reach your gas supplier, call

the fire department.

-

Do not touch any electric switch; do not use

any phone in your building.

-

Immediately call your gas supplier from a

neighbour’s phone. Follow the gas supplier’s

instructions.

C. Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by

hand, don’t try to repair it, call a qualified service

technician. Force or attempted repair may result in a fire or

explosion.

D. Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

INSTALLATION CHECK LIST

check here

1. Has the gas piping been leak tested?

2. Is there at least a 3 inch clearance

between the water heater and

combustible material, 6” at the flue

and sufficient access for servicing at

the front?

3. Have you taken steps to prevent

water damage in case of leaks?

4. Does the area around the heater

have adequate ventilation?

5. Is the dip tube installed in the cold

water inlet connection where

applicable?

6. Is the water heater completely filled

with water?

7. Does the gas piping conform with the

recommendations for your Gas Utility

Company?

8. Is the draft hood and vent pipe

installed properly?

9. Is the draft hood relief opening

unobstructed?

10. Is the temperature and pressure relief

valve installed?

11. Is the drain pipe from the T&P valve

unobstructed?

WARNING: TO AVOID POSSIBLE INJURY, FIRE

AND EXPLOSION, READ THESE PRECAUTIONS

BEFORE ATTEMPTING TO LIGHT OR

RELIGHT THE PILOT.

WARNING:

If you do not follow these instructions exactly, a fire

or explosion may result, causing property damage,

personal injury or loss of life.

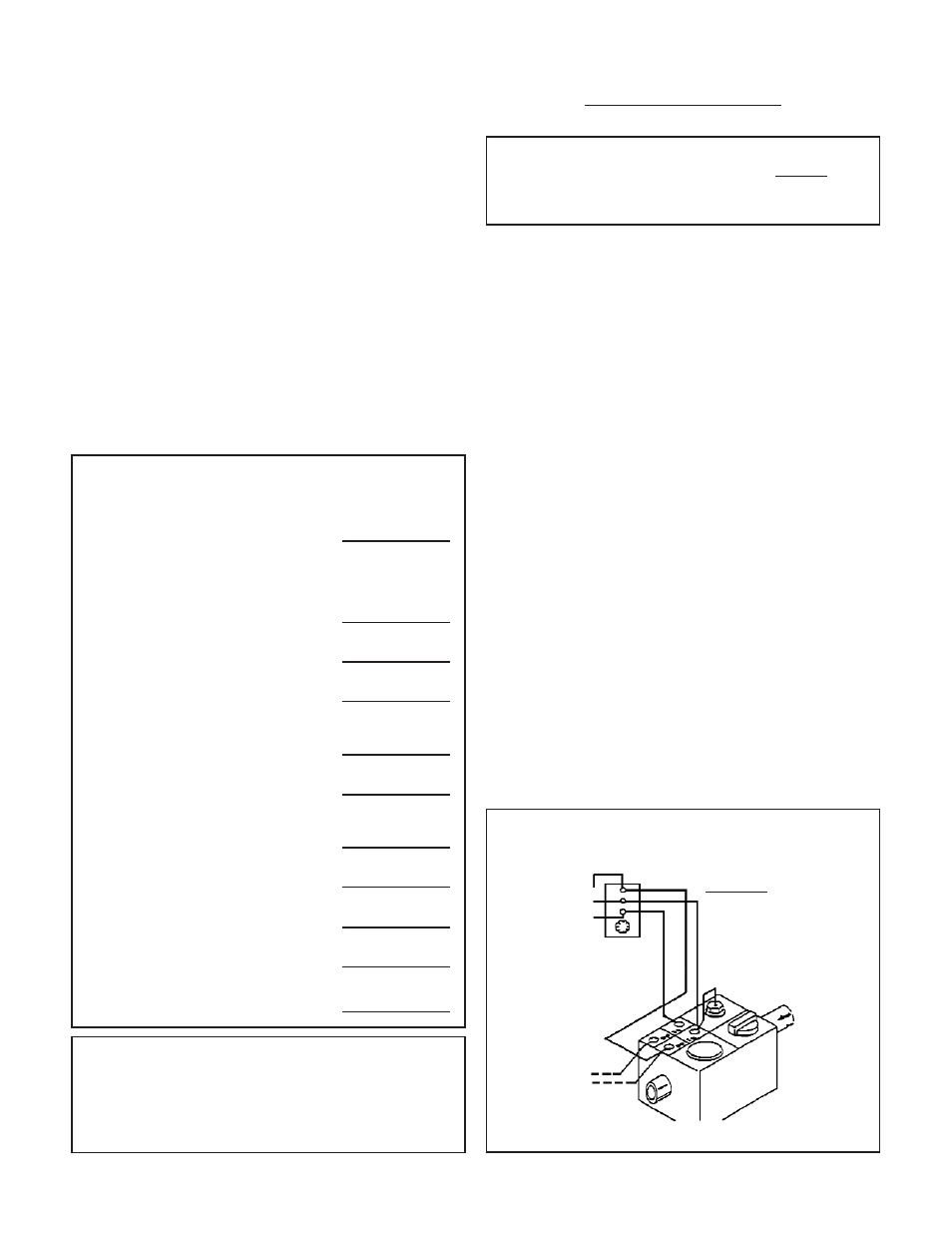

WIRING DIAGRAM, THERMOSTAT TO MAIN GAS VALVE

ECO.

THERM

BLACK

WHITE

RED

IMPORTANT

DO NOT REMOVE

THERMOSTAT FROM

THE WELL WHEN

INSTALLING.

THERMOSTAT WITH

BUILT IN ENERGY

CUT-OFF

TO POWERPILE

GENERATOR

OUTLET

MAIN GAS V

AL

VE

YS-S90 A.C

INLET

80239