John Wood Takagi - 710 User Manual

Page 6

6

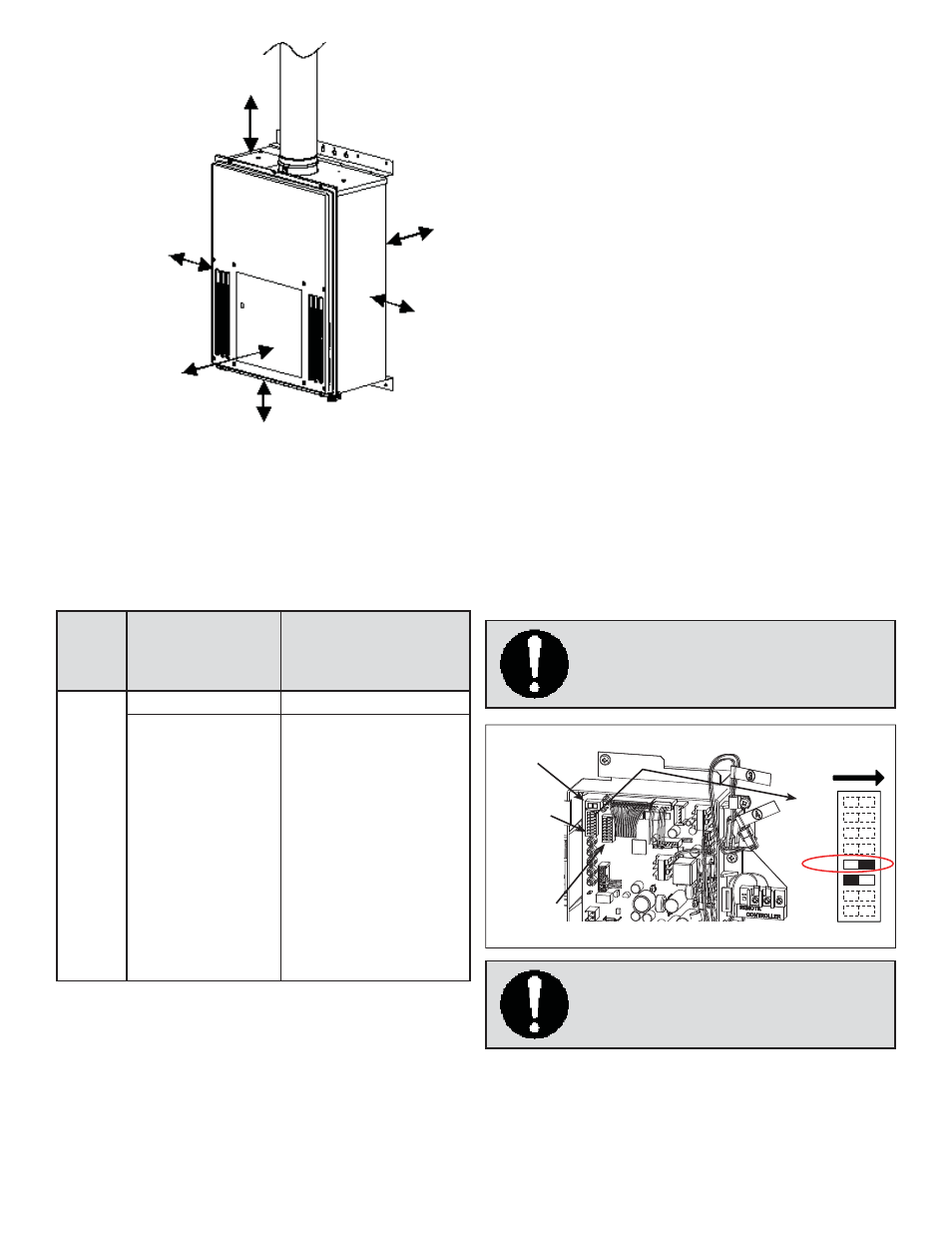

Bottom 305mm

(12 in.)

Back

25mm

(1 in.)

Front 76mm (4 in.)

(610mm (24 in.)

recommended for service)

Top

305mm (12 in.)

Side

(50mm

(2 in.)

Side

(50mm (2 in.)

Combustion Air Supply

The water heater location must provide enough air for

proper combustion and ventilation of the surrounding area.

See the latest edition of B149.1 or any applicable local

codes. In general, these requirements specify that if the unit

is installed in a confined space, there must be a permanent

air supply opening.

Minimum recommended air supply opening size for water

heater:

Water

heater

size

When drawing

make-up air from

outside the

building

When drawing make-

up air from inside the

building (from other

rooms within)

MAX

240,000

BTU/h

103cm

2

(16.0 in

2

)

1548cm

2

(240 in

2

)

When combustion

air is supplied from

outside the building,

an opening commu-

nicating directly with

the outside should

have a minimum

free area of 6.5cm

2

(1 in

2

) per 15,000

BTUH input of the

total input rating of

water heater in the

enclosed area.

When combustion air

is supplied from inside

the building, an open-

ing communicating with

the rest of the dwelling

should have a minimum

free area 6.5cm

2

(1 in

2

)

per 1,000 BTUH input

of the total input rat-

ing of water heater in

the enclosed area. This

opening should never be

less than 1284cm

2

(199

in

2

).

Combustible Air Supplied by Mechanical fan or Make up air

device

The 710 water heater is equipped with a combustible air

sensor that will shut off the unit when inadequate combus-

tible air supply to unit is detected.

• If a mechanical fan or make up air device is used to

supply air to the water heater or utility room, the installer

should make sure it does not create drafts which could

cause nuisance shutdowns.

• If a blower is necessary to provide adequate combustion

air to the water heater, the blower and water heater must

be set up so that the water heater cannot fire unless the

blower is operating. Possible methods include the use of

external flow sensors/transmitters and relays.

Direct Intake Vent System

This 710 water heater may be converted to a direct-vent

(sealed combustion) appliance by installing an adapter (Part

No. TM-DV32) which will bring all required combustible air

from outside the building. When installing the direct-vent

conversion kit, please follow all instructions included with

the kit.

• The 710 must be installed in a location where the proper

amount of combustible air will be available to it at all

times without obstructions.

• If used as a direct-vent appliance, the 710 requires a

102mm (4 in.) combustible air supply pipe. The intake

pipe must be sealed airtight.

• Air supply pipe can be made of ABS, PVC, galvanized

steel, corrugated aluminum, corrugated stainless steel or

Category III stainless steel.

• Change the DIPswitch settings to the direct-vent system.

(See diagram below)

• Sidewall venting is recommended for the direct-vent sys-

tem.

• The manufacturer recommends running the exhaust vent

and the intake pipe parallel.

• The Direct-Vent Conversion Kit has an “INLET” mark

as shown below. Do not reverse the INLET and the

EXHAUST connections when installing vent pipes.

Make sure power to the unit is turned OFF

before changing the DIPswitch settings.

1

2

3

4

5

6

7

8

TMP1

ON

TMP2

TMP3

MODE

DIRE

OUT

D-PRT

MST

The dark square

is the direction the

DIPswitch should

be set to.

Left bank of

DIPswitches

Left Bank of

DIPswitches

7-Seg LED

Right bank of

DIPswitches

Direct-Vent Conversion Kit