John Wood Takagi - 710 User Manual

Page 10

10

Gas Connections

Gas Supply And Gas Pipe Sizing

Turn off all electric power to the water heater if service

is to be performed.

Turn the manual gas valve located on the outside of

the unit clockwise to the off position.

1.

2.

TO TURN OFF GAS TO

APPLIANCE

WARNING

Conversion of this unit from natural gas

to propane or vise versa will void all war-

ranty. Contact your local distributor to get

the correct unit for your gas type. The

manufacturer is not liable for any property

and/or personal damage resulting from gas

conversions.

*Check that the type of gas matches the rating plate

first.

1. The minimum and maximum inlet gas pressures are:

Gas type

Inlet gas pressure

Natural Gas

Min.: 5.0" WC – Max.: 10.5" WC

Propane Gas

Min.: 8.0" WC – Max.: 14.0" WC

2. Gas pressure below this specified range for the 710

and/or insufficient gas volume will adversely affect per-

formance. These pressures are measured when the 710

is in full operation.

3. Inlet gas pressure must not exceed the above maximum

values; gas pressure above the specified range will

cause dangerous operating conditions and damage to

the unit. Ensure that any and all gas regulators used

are operating properly and are providing gas pressures

within the specified range shown above.

4. Until testing of the main gas line supply pressure is com-

pleted, ensure the gas line to the 710 is disconnected to

avoid any damage to the water heater.

Measuring Inlet Gas Pressure

The 710 cannot perform properly without sufficient inlet

gas pressure. Below are instructions on how to check the

inlet gas pressure. THIS IS ONLY TO BE DONE BY A

LICENSED PROFESSIONAL.

1. Shut off the manual gas valve on the supply gas line.

2. Open a faucet. The unit should turn on and the gas in the

gas pipe line should purge. Leave the faucet on to keep

the unit running until the unit shut down due to lack of gas

supply. Then shut the faucet off.

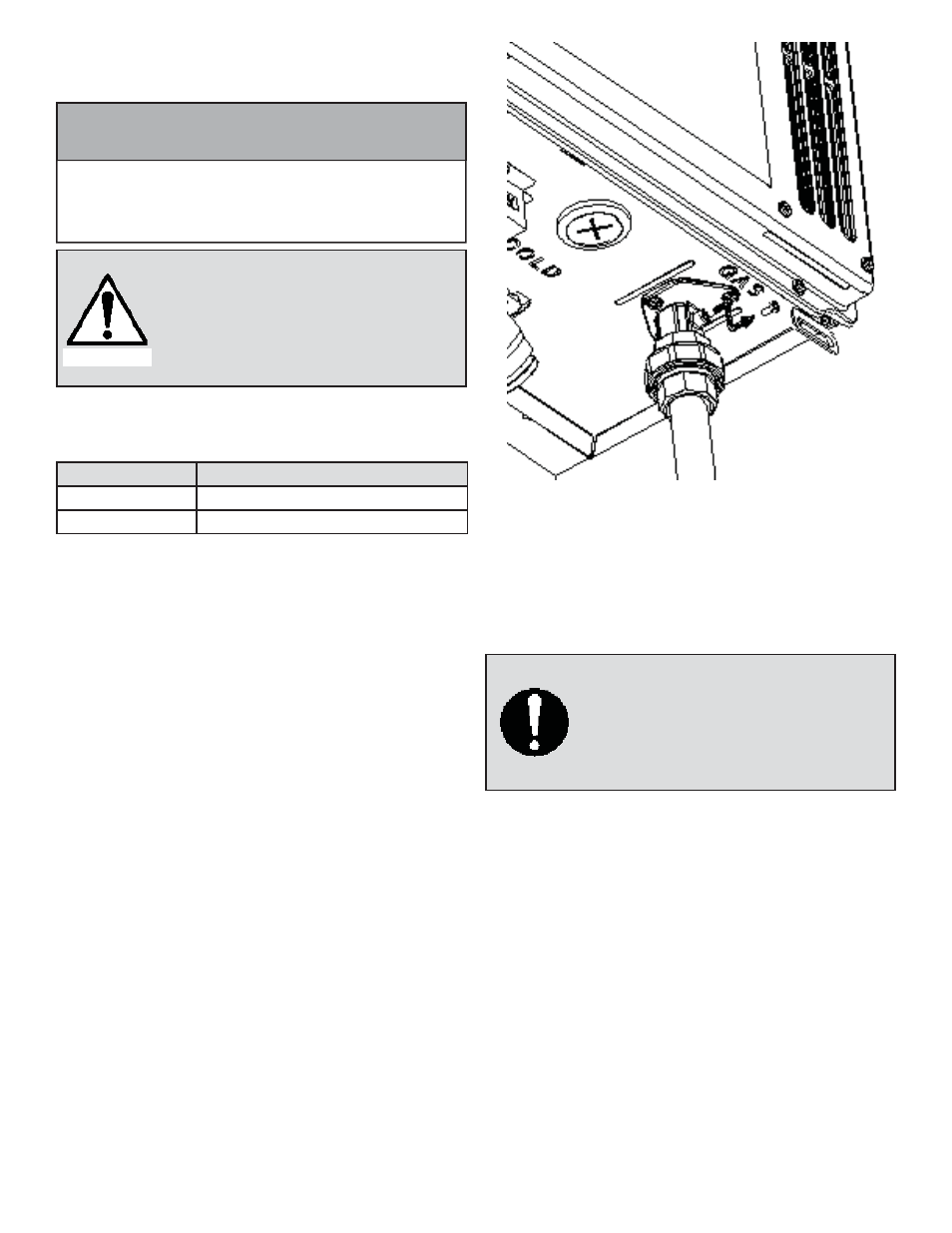

3. Remove the screw for the pressure port located on the

gas inlet of the 710 shown in the diagram to the right.

4. Connect the manometer to the pressure port.

5. Re-open the manual gas valve. Check to see that there

are no gas leaks.

6. Open some of the fixtures that use the highest flow rate

to turn on the 710.

7. Check the inlet gas pressure. When 710 is on a maxi-

mum burn, the manometer should read from 5.0” to 10.5”

WC for Natural gas, from 8.0” to 14.0” WC for Liquid

Propane.

Size the gas pipe appropriately to supply

the necessary volume of gas required for

the 710 models (240,000 BTU/h for both

Natural Gas and Liquid Propane) using

CSA B149.1 or local codes. Otherwise, flow

capabilities and output temperatures will be

limited.

Install a manual gas shut-off valve between the 710 and

the gas supply line.

When the gas connections are completed, it is necessary

to perform a gas leak test either by applying soapy water

to all gas fittings and observing for bubbles or by using a

gas leak detection device.

Always purge the gas line of any debris and/or water

before connecting to the gas inlet.

1.

2.

3.