For your safety, read before operating, Water connections – John Wood Takagi - 320H-520H User Manual

Page 15

15

Water connections

FOR YOUR SAFETY, READ

BEFORE OPERATING

Do not use this water heater if any part has been sub-

mersed under water. Immediately call a licensed profes-

sional to inspect the water heater and to replace any

damaged parts.

All pipes, pipe fittings, valves and other components,

including soldering materials, must be suitable for pota-

ble water systems.

A manual shut off valve must be installed on the cold

water inlet to the water heater between the main water

supply line and the water heater.

In addition, a manual shut off valve is also recommended

on the hot water outlet of the unit. If the water heater is

installed within, or subjected to, a closed loop water sys-

tem, a thermal expansion tank must be installed.

Before installing the water heater, flush the water line

to remove all debris, and after installation is complete,

purge the air from the line. Failure to do so may cause

damage to the heater.

There is a wire mesh filter within the cold inlet to trap

debris from entering your heater. This will need to be

cleaned periodically to maintain optimum flow.

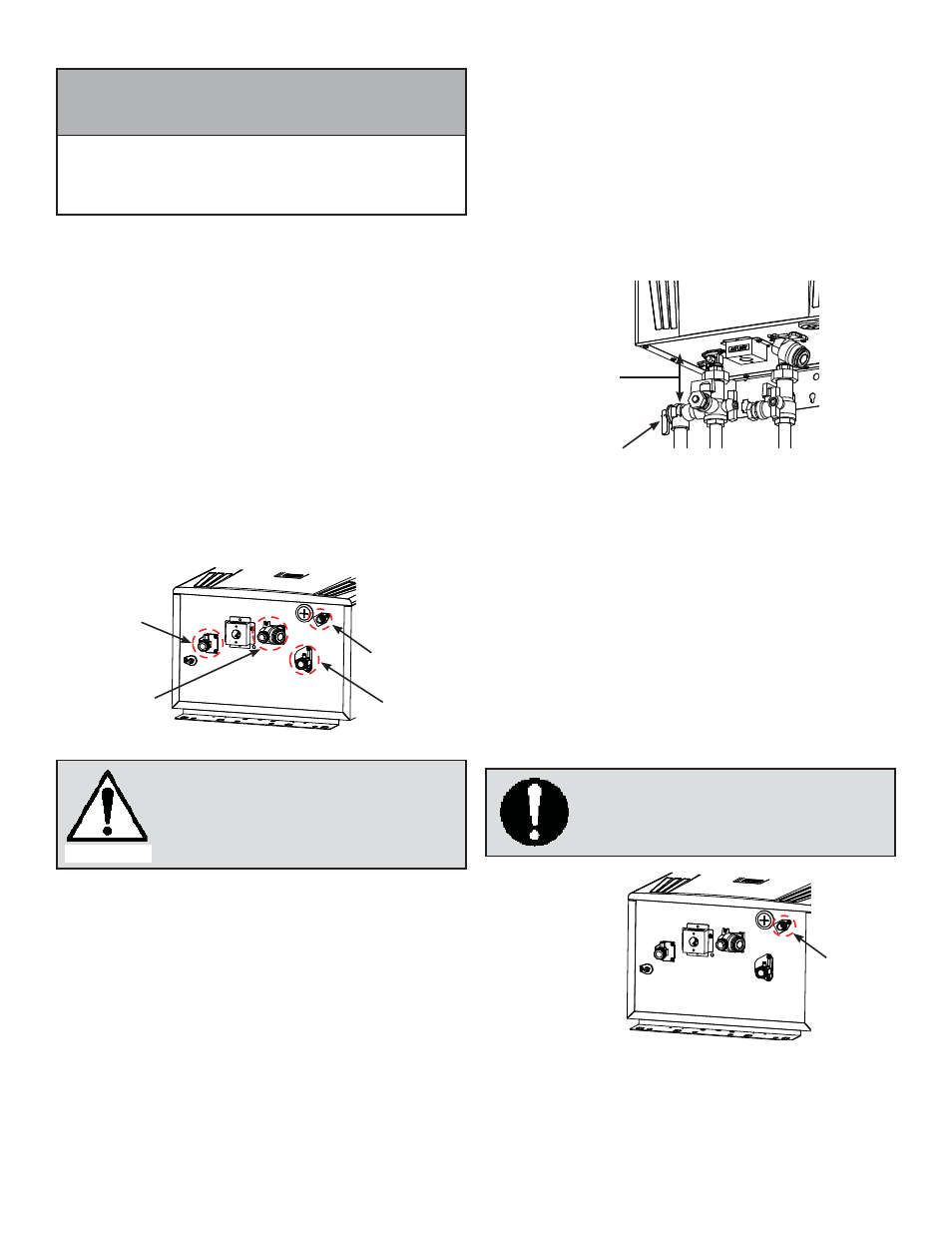

Water intlet

(Cold)

Gas intlet

Condensate

drain port

Water outlet

(Hot)

WARNING

Do not reverse the hot outlet and cold inlet

connections to the 520H Water Heater. This

will not properly active the water heater.

Pressure Relief Valve

The 520H has a high-temperature shut off switch built in as

a standard safety feature (called a Hi-Limit switch) therefore

a “pressure only" relief valve is required.

This unit does not come with an approved pressure relief

valve.

An approved pressure relief valve must be installed on

the hot water outlet.

The pressure relief valve must conform to ANSI Z21.22

or CAN 1-4.4 and installation must follow local code.

The discharge capacity must be at least 199,000 BTU/

h.

The pressure relief valve needs to be rated for a maxi-

mum of 150 psi.

1.

2.

3.

4.

5.

1.

2.

3.

4.

5.

The discharge piping for the pressure relief valve must

be directed so that the hot water cannot splash on any-

one or on nearby equipment.

Attach the discharge tube to the pressure relief valve and

run the end of the tube to within 150mm (6 in.) from the

floor. This discharge tube must allow free and complete

drainage without any restrictions.

If the pressure relief valve installed on the 520H dis-

charges periodically, this may be due to a defective ther-

mal expansion tank or defective pressure relief valve.

The pressure relief valve must be manually operated

periodically to check for correct operation.

Hot outlet

Cold intlet

Gas intlet

As close as

possible

Pressure

Relief Valve

Condensate Drain

The 520H does not include a built-in condensate neutral-

izer cartridge for reducing the pH level of condensate

water. If local codes dictate that condensate must be

neutralized prior to drainage, a condensate neutralizer

must be installed. An accessory Neutralizer assembly is

sold separately.

In the absence of applicable local codes and regulations,

the manufacturer recommends that condensate be dis-

posed of into a standard drain. Connect a drain tube from

the condensate drain port (shown below) located on the

bottom of the water heater to a standard drain.

Follow all code requirements of the local

authority on condensate neutralizers and

whether or not they are required for the

installation.

Condensate

drain port

6.

7.

8.

9.

•

•