4) if a vent riser is required, Iii) gas piping, Leak testing – John Wood Superflue Power Vent (before FVIR technology) User Manual

Page 8

-6-

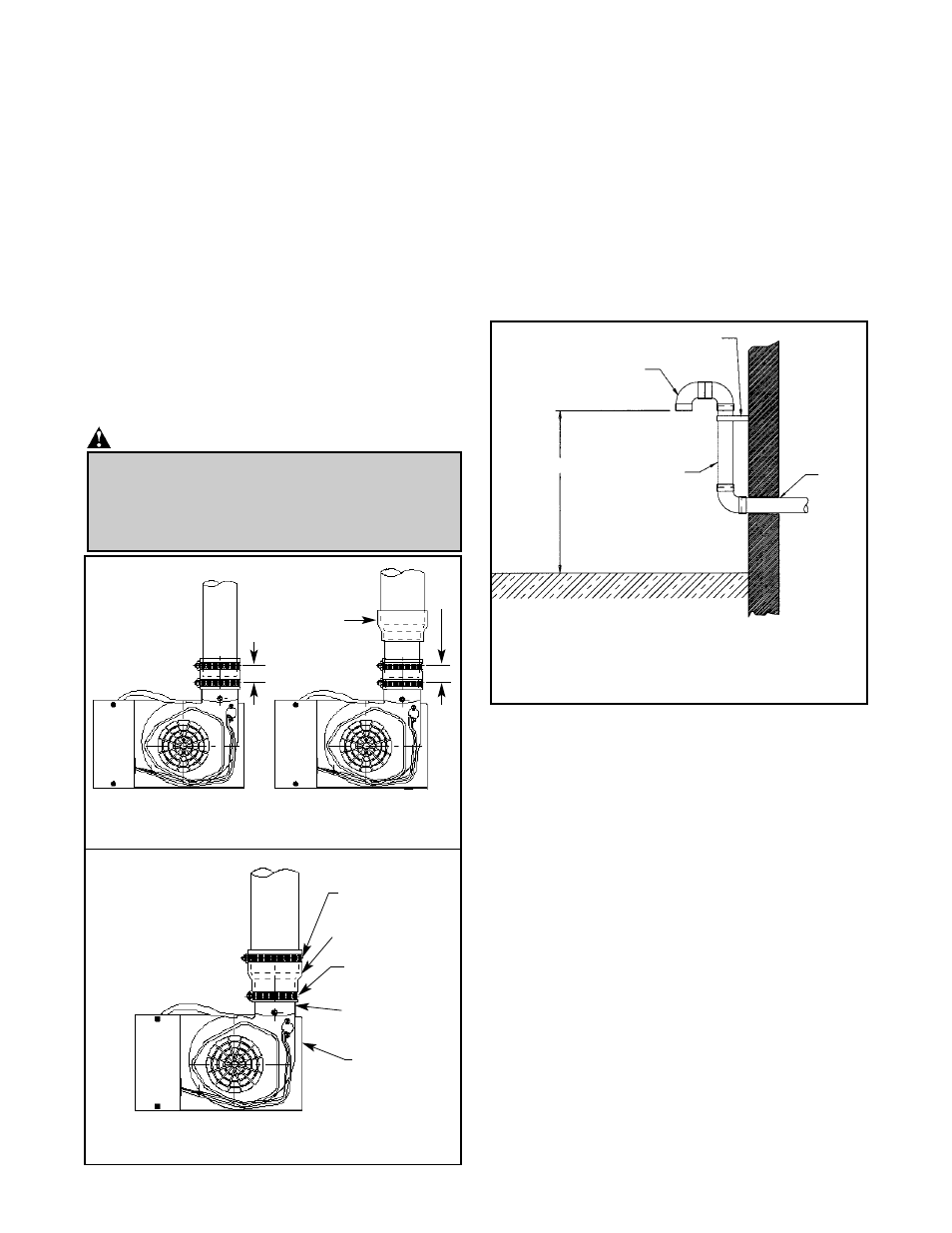

3) BLOWER RUBBER COUPLING

CONNECTION

(See figure 5)

1. Clean and slightly sand the end of the vent pipe

that will connect to the rubber coupling. This will

ensure a good mechanical connection between the

coupling and the pipe.

2. At the rubber coupling, loosen the top gear clamp

to allow the vent piping to be inserted fully 1–1/4”

(32mm) deep. Do not use sealant or glue.

3. Tighten the top gear clamp to ensure that the vent

pipe is firmly secured, and gas tight.

4. Check that the bottom gear clamp is firmly seated,

secured, and gas tight.

5. As a final check, the vent pipe should be gently

moved side to side and vertically. There should be

no slippage or movement of the vent pipe within the

coupling.

BLOWER ASSY WITH RUBBER COU-

PLING: FOR 2” NOMINAL PIPE

BLOWER ASSY WITH RUBBER COU-

PLING: FOR 3” NOMINAL PIPE

BLOWER ASSEMBLY WITH RUBBER

COUPLING: FOR 3” NOMINAL PIPE

MODELS DESIGNED FOR USE WITH 2” OR 3” PIPE

MODELS DESIGNED FOR USE WITH 3” PIPE ONLY

Figure 5

Figure 6

4) IF A VENT RISER IS REQUIRED

1. Fabricate the vent riser to lift the termination elbow

to the height required.

2. Fasten the assembly to the outside wall with brack-

ets. See Figure 6. Bracket is to be supplied by

installer.

3. Extend the horizontal run of pipe a convenient dis-

tance through the wall to make further work easy.

4. Connect vent riser assembly to the rest of the vent-

ing system.

BRACKET

VENT RISER

CAULK

ATTACH 90° TERMINATION

ELBOW

12” MIN.

CONDENSATION

TRAP & DRAIN

GROUND LEVEL OR MAXIMUM SNOW LINE

VENT PIPING MAY BE SLOPED IN ANY DIRECTION, AS LONG AS A

WATER TRAP IS NOT CREATED IN THE VENTING SYSTEM. THE

SLOPE SHOULD BE KEPT TO A MINIMUM SO AS NOT TO EXERT ANY

UNDUE STRESS ON THE PIPE.

INSTALLATION OF FABRICATED VENT RISER

III)

GAS PIPING

Install the gas piping as indicated in Figure 7. Use only

new pipe and fittings, with sound, clean–cut pipe

threads. Sealing compound must conform to the applic-

able code for pipe sealing compounds for use with nat-

ural gas and propane.

A manual gas shut–off valve must be installed ahead of

a union of the ground– joint type to the gas valve. At

the gas control, a sediment trap must be installed.

The maximum inlet gas pressure must not exceed 1/2

PSIG (14” W.C.). For input adjustment, the minimum

inlet gas pressure is 1/28 PSIG (1” W.C.) above the

manifold pressure shown on the water heater rating

plate.

LEAK TESTING

The water heater and its gas line connections must be

leak tested before putting the water heater in operation.

CAUTION

• DO NOT OVERTIGHTEN THE TOP AND BOT-

TOM GEAR CLAMPS OF THE RUBBER COU-

PLING.

• DO NOT APPLY SOLVENT CEMENT OR SILI-

CONE TO THE RUBBER COUPLING CONNEC-

TION.

1 1/4”

(32mm)

1 1/4”

(32mm)

REDUCER

2” - 3”

TOP GEAR

CLAMP

RUBBER

COUPLING

BOTTOM

GEAR

CLAMP

BLOWER OUT-

LET FLANGE

BLOWER