John Wood Superflue Power Vent (before FVIR technology) User Manual

Page 16

-14-

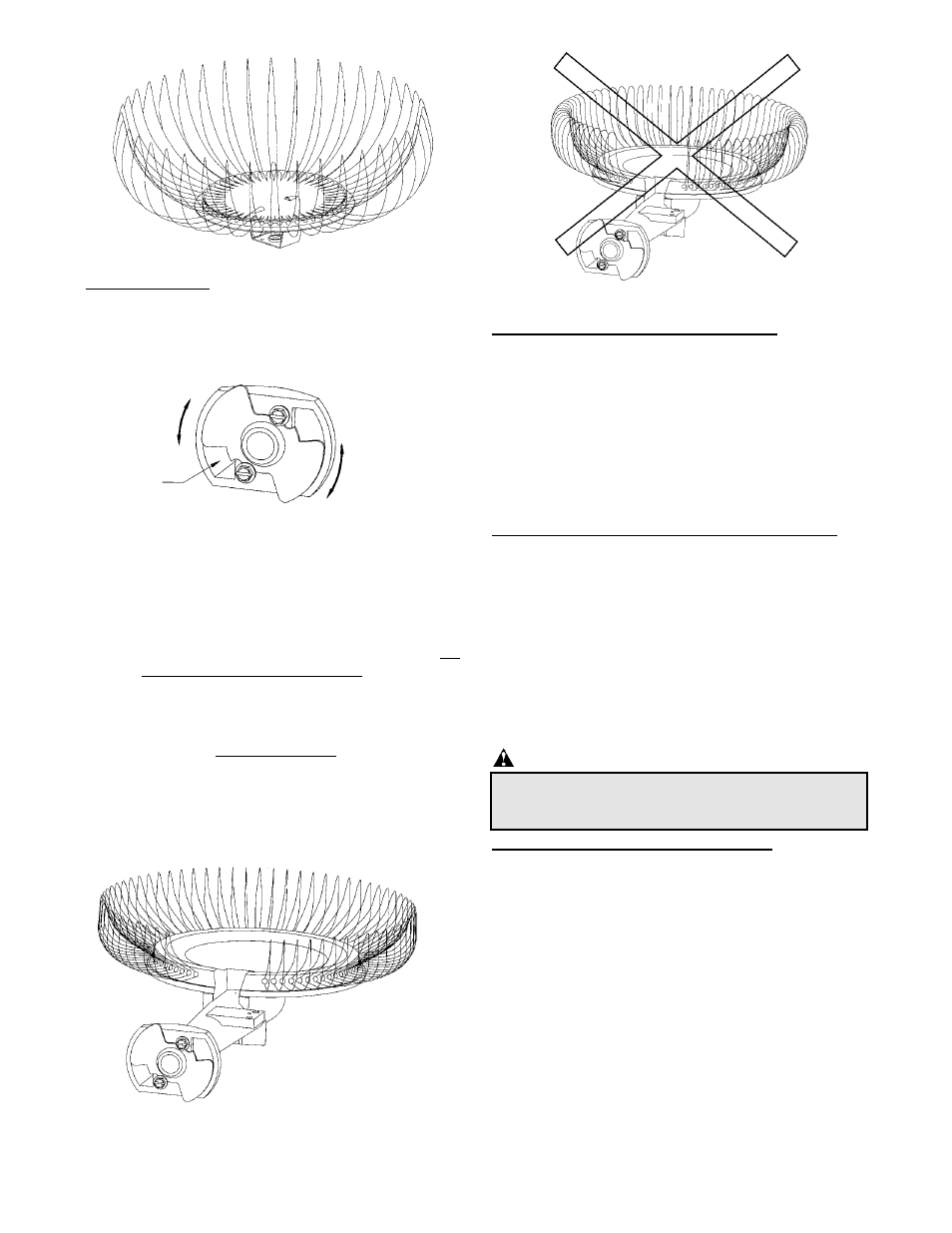

Figure 15 (continued)

Figure 15

Figure 13

Cast Iron Burner

1. Observe the flame pattern on the burner.

2. Observe the primary air openings of the burner.

(See Figure 14) If lint and dust have accumulated,

clean it up with a soft brush.

3. If the flame pattern is not a soft, blue flame the pri-

mary air may need adjustment:

a. Loosen the air shutter screws and open the air

shutter, to admit more primary air. If the flame

becomes hard and tends to lift away from the

burner ports, close the air shutter a little. Do

this adjustment a little at a time.

b. When you have adjusted the primary air cor-

rectly, there should not be any tendency of the

flame to lift, nor should the flame be yellow and

luminous. Slight yellow tips of the flame are

normal. Tighten the air shutter adjustment

screws.

PRIMARY AIR

CLOSED

OPEN

Figure 14

Combustion Chamber Cleaning:

THIS WILL REQUIRE SUFFICIENT TIME FOR THE

WATER HEATER TO COOL DOWN. UNPLUG THE

POWER CORD AND WAIT 1 HOUR MINIMUM. WEAR

PROTECTIVE CLOTHING (LONG SLEEVES AND

GLOVES) AS METAL COMPONENTS MAY STILL BE HOT

ENOUGH TO BURN EXPOSED SKIN.

1. Remove outer door.

2. Slide inner door open.

3. Use vacuum to clean top burner and radiation

shield.

Temperature and Pressure Relief Valve

Check the temperature and pressure relief valve (T&P

valve) to ensure that it functions properly and there is

no blockage.

Lift the operating lever to release water and let it snap

shut. The water should stop instantly upon release of

the lever.

If the temperature and pressure relief valve on the

water heater discharges periodically, this may be due

to thermal expansion in a closed water supply system.

Contact the water supplier or local plumbing inspector

on how to correct this situation.

CAUTION:

The escaping water will be hot. Stand clear. Make

sure the out–flowing water will not cause injury or

damage near the heater.

Anode and Cathodic Protection

In order to protect the tank, a magnesium anode has

been installed in the tank. Depending on local water

conditions, this anode may have to be replaced from

time to time. It is not possible to make any predictions

for the expected life of the anode. Anodes have been

known to last for 20 or more years, but sometimes

have had to be replaced in as few as 2 years.

In protecting the tank interior from rusting, the anode

will be consumed through an electrolytic action.

On a new installation, it is recommended that the

anode be inspected annually to establish a pattern of

consumption. Further inspections can be made

accordingly.

Once an anode has been consumed such that 4” or

more of the steel core wire is exposed, the anode must

be replaced.

YELLOW FLAMES

GOOD BLUE FLAMES