John Wood Power Direct Vent (ENERGY STAR) User Manual

Page 9

Vent Pipe Connection to Blower

A rubber coupling and gear clamps are supplied (Vent Kit)

with the water heater to connect the exhaust vent system to

the blower.

Important: These connections must be properly sealed to

prevent the leakage of the products of combustion into the

living area.

Vent Pipe Installation

The following guidelines should be followed when installing

the air intake and exhaust vent system:

•

Venting should be as direct as possible with a minimum

number of pipe fittings.

•

Vent diameter must not be reduced unless specifically

noted in the installation instructions.

•

Support all horizontal pipe runs every 1.2m (4 ft.) and all

vertical pipe runs every 1.5m (5 ft.) or according to local

codes.

•

Vents run through unconditioned spaces where below

freezing temperatures are expected, are not recom-

mended.

•

Vents run through unconditioned spaces inside a building

may result in the condensation of flue gases during the

winter season. The rubber coupling joined to the blower

includes a nipple with a yellow cap. In installations such

as this connect a condensation trap to this nipple.

The combustion air intake and exhaust vent system and

termination may be installed in one of the following type

terminations:

1. Horizontal (2 Pipe) (air intake and exhaust vent)

2. Vertical (2 Pipe) (air intake and exhaust vent)

3. Concentric Vent Termination (using Concentric Vent Kit

side wall termination only).

All pipe, fittings, pipe cement, primers and procedures

must conform to American National Standard Institute and

American Society for Testing and Materials (ANSI/ASTM)

standards in the United States. This water heater has been

design certified by CSA International for use with the speci-

fied (CSA) listed plastic vent pipe.

CAUTION:

Use of Solvent Cement and Primer

• Use only in well-ventilated areas.

• Do not use near flame or open fire.

• Use only the Solvent Cement and Primer

appropriate for the venting material being

used.

• Solvent cements for plastic pipe are flam-

mable liquids and must be kept away from

all sources of ignition.

Do not use solvent cement to connect the exhaust vent sys-

tem to the blower. Use the rubber coupling and gear clamps

instead. This connection must be removable to service the

heater. All other joints in the air intake and exhaust vent

systems must be properly cemented. Use an appropriate

solvent cement to connect the 3 in. to 2 in adapter/reducer

to air intake on the water heater.

1. Cut the pipe end square and remove all ragged edges

and burrs. Make sure the inside of the pipe is clean and

free of cuttings and loose dirt. Chamfer the end and apply

primer to the fi tting and pipe.

2. Using a suitable grade of pipe cement, apply a moderate,

even coat inside the fi tting. Apply a liberal amount of

cement to the outside of the pipe to socket depth.

Note: It is important to select the proper pipe cement for the

type plastic pipe being used.

3. Assemble the parts quickly while the cement is still wet.

Twist the pipe 1/4 turn during insertion and hold for 30

seconds.

Vent Pipe Length

The maximum allowable pipe lengths for air intake and

exhaust are listed in Table 1. The specified maximum

lengths are for each of the intake and exhaust systems and

not for the combined lengths of both systems. In addition,

each system requires a 45° long sweep elbow termination

with a restrictive screen. Minimum pipe length is 900mm (3

ft.) with a minimum of one 90° elbow per side.

1. Determine termination type and pipe size.

2. Determine number of elbows in vent system. Do not

include termination elbow. Calculate the maximum

equivalent length of the exhaust and air intake system.

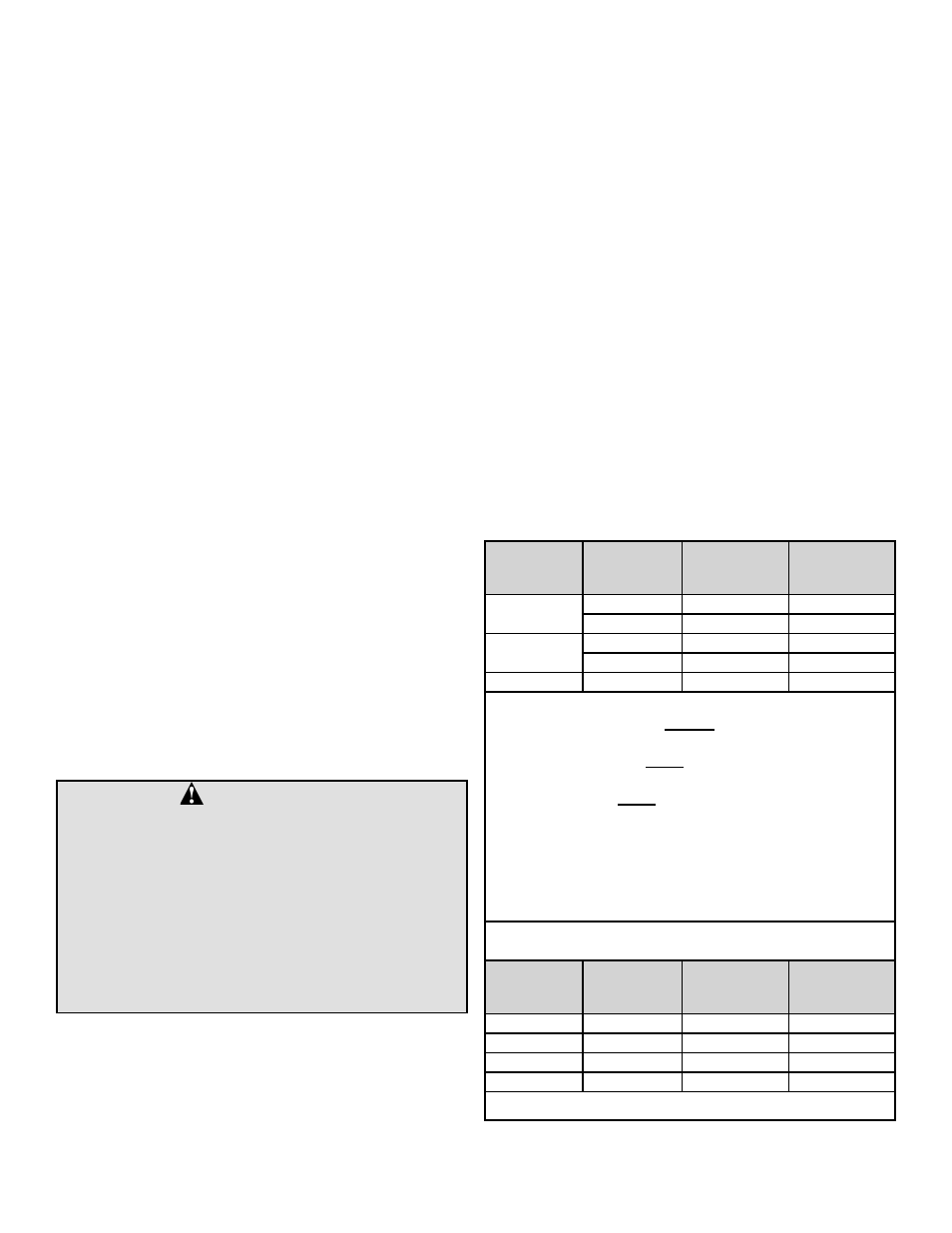

MODEL

NUMBER

VENT PIPE

DIAMETER

CONCENTRIC

VENT

LENGTH

2 PIPE VENT

LENGTH

4040SN-PDV

50mm (2 in.)

15.2m (50 ft.)

15.2m (50 ft.)

76mm (3 in.)

30.5m (100 ft.) 30.5m (100 ft.)

5040SN-PDV

50mm (2 in.)

15.2m (50 ft.)

15.2m (50 ft.)

76mm (3 in.)

30.5m (100 ft.) 30.5m (100 ft.)

5065SN-PDV

76mm (3 in.)

9.2m (30 ft.)

15.3m (50 ft.)

Notes:

3. Vent lengths shown do not include vent termination

elbow.

4. A horizontal vent must have a 45° vent termination

elbow to direct the vent pipe downward.

5. A vertical vent must have a 90° vent termination elbow

to direct the vent pipe horizontally followed by a 45°

elbow to direct the vent pipe downward.

6. If additional elbows are used in the vent system the

allowable vent lengths are reduced (see chart below).

7. Two 45° elbows are considered the equivalent of one

90° elbow.

Equivalent lengths of straight pipe for various elbows

using Schedule 40 PVC or CPVC or polypropylene.

SIZE

TYPE

SHORT

SWEEP/

RADIUS

LONG

SWEEP/

RADIUS

50mm (2 in.)

90°

2.44m (8 ft.)

1.52m (5 ft.)

76mm (3 in.)

90°

2.44m (8 ft.)

1.52m (5 ft.)

50mm (2 in.)

45°

1.22m (4 ft.)

0.76m (2.5 ft.)

76mm (3 in.)

45°

1.22m (4 ft.)

0.76m (2.5 ft.)

Table 1. Maximum Allowable Vent Lengths

– 9 –