Burner flames, Stacking, Emergency shut down – John Wood Power Direct Vent (ENERGY STAR) User Manual

Page 26: Operational conditions

V) OPERATION

WARNING

Keep the area around the heater clear and

unobstructed.

Water Heater Operation

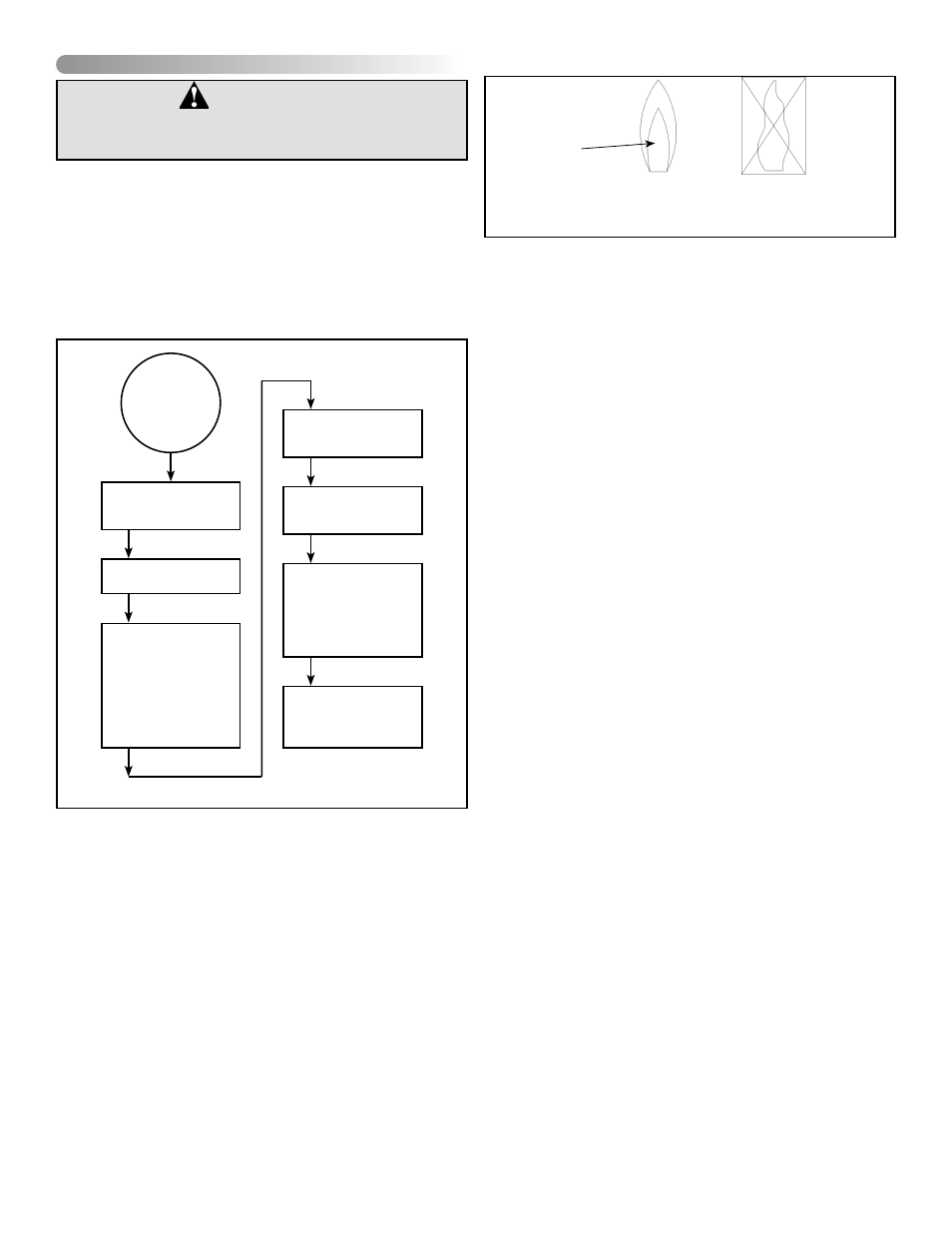

Figure 21 shows the water heater's sequence of operation

when a call for heat is initiated. The ignition control module

will attempt to light the burner three times. If the ignition

control does not detect ignition it will enter lockout mode.

The Robertshaw control will display a System Status Code

(see Table 3), the White-Rodgers control will flash the cor-

responding error code.

CONTROL CHECKS TO

ENSURE PRESSURE

SWITCH IS OPEN

BLOWER IS

ENERGIZED

CONTROL CHECKS TO

ENSURE PRESSURE

SWITCH CLOSES

INDICATING BLOWER

IS OPERATING AND

THERE ARE NO

VENTING BLOCKAGES

(INLET OR OUTLET)

IGNITER IS

ENERGIZED AND MAIN

VALVE IS OPENED

MAIN BURNER ON

AND THE FLAME IS

SENSED BY CONTROL

MAIN BURNER

CONTINUES TILL THE

WATER IN THE TANK

REACHES

THERMOSTAT

SETTING

MAIN BURNER SHUTS

OFF. BLOWER

CONTINUES FOR A

POST PURGE TIME

CALL FOR

HEAT

Figure 21. Sequence Of Operation

Burner Flames

CORRECT FLAME

SOFT BLUE

INCORRECT

FLAME LAZY

YELLOW

Figure 22. Flame Characteristics

TIPS MAY HAVE

A YELLOW TINT

YELLOW INNER

CONES ARE

SATISFACTORY

Inspect the burner flames through the viewport and compare

them to the drawings in Figure 22. A properly operating

burner should produce a soft blue flame. Blue tips with yel-

low inner cones are satisfactory. The tips of the flame may

have a slight yellow tint. The flame should not be all yellow

or have a sharp blue-orange colour. Contaminated air may

cause an orange coloured flame. Contact a qualified service

technician if the flame is not satisfactory.

Stacking

Stacking occurs when a series of short draws of hot water

(11 litres (3 US gallons) or less) are taken from the water

heater tank. This causes increased cycling of the burner and

can result in increased water temperatures at the hot water

outlet. A tempering device is recommended in the hot water

supply line to reduce the risk of scald injury.

Emergency Shut Down

Important: Should overheating occur or the gas supply fails

to shut off, turn off the water heater’s manual gas control

valve and call a qualified service technician.

The thermostat is adjusted to its lowest temperature when it

is shipped from the factory. Water temperature can be regu-

lated by moving the temperature dial to the preferred setting.

The preferred starting point is 49°C (120°F). Align the index

bar on the thermostat with the desired water temperature as

shown in Figure 18. There is a hot water scald potential if

the thermostat is set too high.

Note: During low demand periods when hot water is not

being used, a lower thermostat setting will reduce energy

losses and may satisfy your normal hot water needs. If hot

water use is expected to be more than normal, a higher

thermostat setting may be required to meet the increased

demand. When leaving your home for extended periods

(vacations, etc.) turn the temperature dial to its lowest set-

ting. This will maintain the water at low temperatures with

minimum energy losses and prevent the tank from freezing

during cold weather.

Operational Conditions

Condensation

Moisture from the products of combustion condenses on the

tank surface and the outside jacket of the water heater and

forms drops of water, which may fall onto the burner or other

hot surfaces. This will produce a “sizzling” or “frying” noise.

This condensation is normal and should not be confused

with a leaking tank. Condensation may increase or decrease

at different times of the year.

– 26 –