John Wood Envirosense Power Direct Vent (prior to May 2010) User Manual

Page 19

19

InstallatIon of vent sYsteM

Before beginning installation of piping system thoroughly read

the section of this manual VENT PIPE PREPARATION.

If you are installing your system so that it vents through roof,

please refer to section titled INSTALLATION OF VERTICAL

VENT SYSTEM.

vent terMInal InstallatIon, sIdewall

1. Install the vent terminal by using the cover plate as a template

to mark the hole for the vent pipe to pass through the wall.

BEWARE OF CONCEALED WIRING AND PIPING INSIDE

THE WALL.

2. If the Vent Terminal is being installed on the outside of a

finished wall, it may be easier to mark both the inside and

outside wall. Align the holes by drilling a hole through the

center of the template from the inside through to the outside.

The template can now be positioned on the outside wall using

the drilled hole as a centering point for the template.

3. A) MASONRY SIDE WALLS

Chisel an opening approximately one half inch (1.3 cm) larger

than the marked circle.

B) WOODEN SIDE WALLS

Drill a pilot hole approximately one quarter inch (0.64 cm) outside

of the marked circle. This pilot hole is used as a starting point

for a saws-all or sabre saw blade. Cut around the marked

circle staying approximately one quarter inch (0.64 cm) outside

of the line. (This will allow the vent to easily slide through

the opening. The resulting gap will be covered up by the

Vent Terminal cover plate.) Repeat this step on inside wall if

necessary.

sequence of InstallatIons, fIGure 18a

Cut a length of PVC pipe about 3.5 inches (8.9 cm) longer than the

wall thickness at the opening. Glue the vent terminal to this

section of pipe. Slide the wall plate over the pipe to stop against

the vent terminal. Place a bead of caulking (not supplied) around

the gap between the pipe and cover plate. Apply enough to

fill some of the gap between the pipe and wall. Place some of

the caulking on the back of the plate to hold it against the wall

after installation. If the vent pipe is installed up to the wall, with

a coupling on the end against the wall opening, the pipe with

the vent terminal can be prepared for gluing before inserting

through the wall. Slide the pipe through the wall and insert

into the coupling on the other side of the wall, making sure that

the vent terminal ends up pointed in the correct position, see

Figure 15.

vent terMInatIon - fIGure 15.

dIrect ventInG

The air intake provided on the unit contains a mesh screen to prevent

large particles from entering the unit.

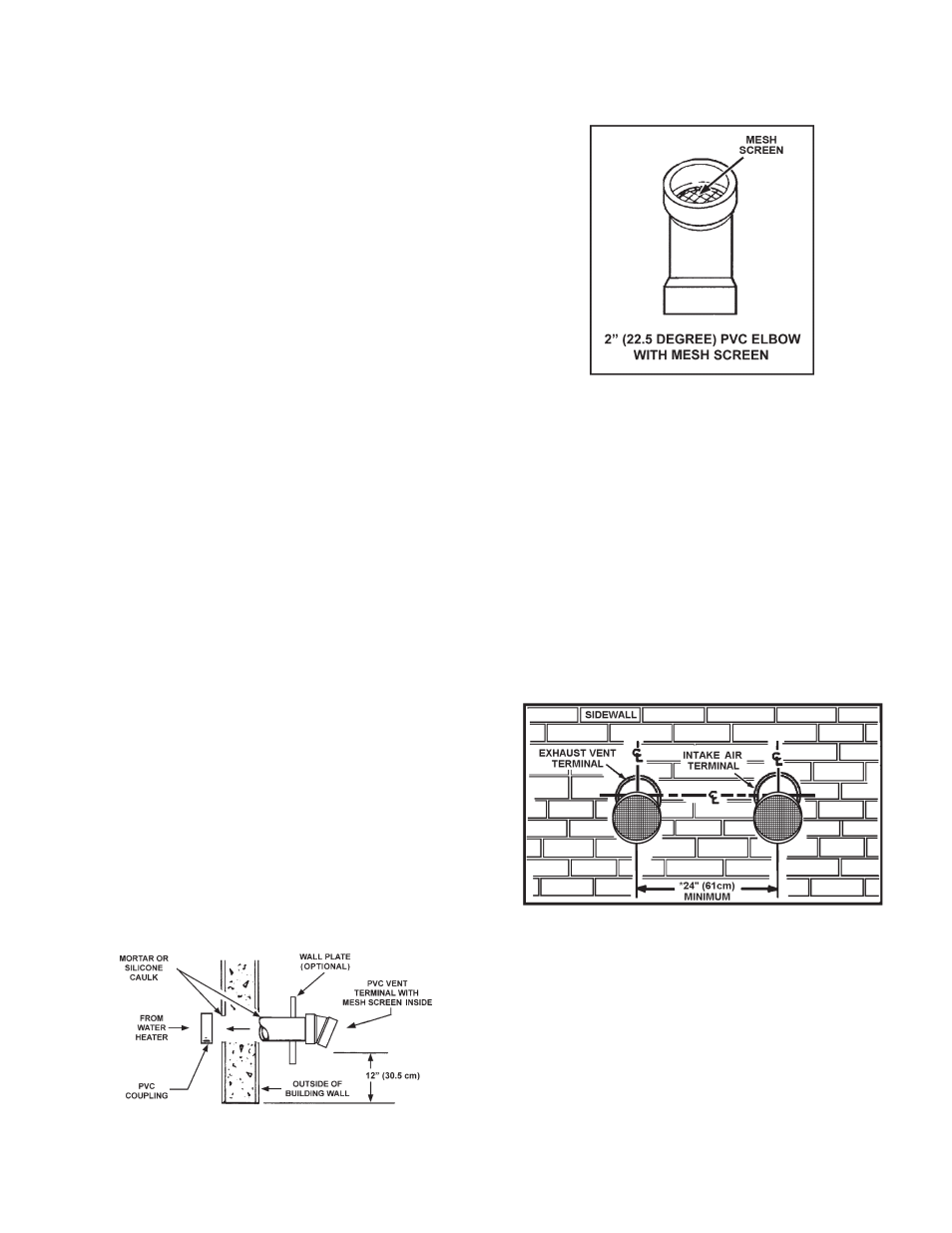

fIGure 16.

WHEN THE UNIT IS TO BE SETUP AS A DIRECT VENT, THE

MESH SCREEN MUST BE REMOVED. THE INLET VENT PIPE

MAY THEN BE GLUED TO THE AIR INTAKE (See Figure 18B)

PROVIDED ON THE UNIT. THE SCREEN REMOVED FROM THE

INTAKE NEEDS TO BE INSERTED INTO THE 2” - 22.5 DEGREE

VENT TERMINAL SUPPLIED IN THE VENT TERMINAL KIT.

dIrect vent terMInal InstallatIon IMportant

THIS UNIT CONSISTS OF TWO VENT TERMINALS - AN INTAKE

VENT TERMINAL AND AN EXHAUST VENT TERMINAL. THE INTAKE

VENT TERMINAL IS A 2” 22.5° PVC ELBOW(-) WITH A MESH

SCREEN AND THE EXHAUST VENT TERMINAL IS A 2” 22.5° PVC

ELBOW WITH A MESH SCREEN.

NOTE: TO PREVENT EXHAUSTING PRODUCTS FROM

CIRCULATING TO THE AIR INTAKE IN WINDY/COLD AREAS,

THE MAXIMUM PRACTICAL DISTANCE BETWEEN THESE TWO

TERMINALS IS RECOMMENDED.

fIGure 17.

WHEN LOCATING THE TERMINALS ON A SIDEWALL, THE

FOLLOWING SPECIFICATIONS PERTAINING TO TERMINAL

LOCATION MUST BE FOLLOWED.

1. The intake air terminal and the exhaust vent terminal must terminate

on the same exterior wall and must be separated by a minimum of

24” (61cm) on vertical centerline (see Figure 18C). In colder climates

increasing the 24” (61cm) minimum will reduce possibility of frost

over from side winds blowing exhaust vapors to the air intake of the

direct vent.

2. The horizontal centerline of the intake air terminal may not be located

lower than the horizontal centerline of the exhaust vent terminal (see

Figure 17).