Troubleshooting guidelines – John Wood Envirosense Power Vent User Manual

Page 32

32

trouBleshootInG GuIdelInes

trouBle shootInG

Please check guidelines below. For your safety, water heater service should be performed only by a qualified service technician.

Read the GENERAL SAFETY INFORMATION section first.

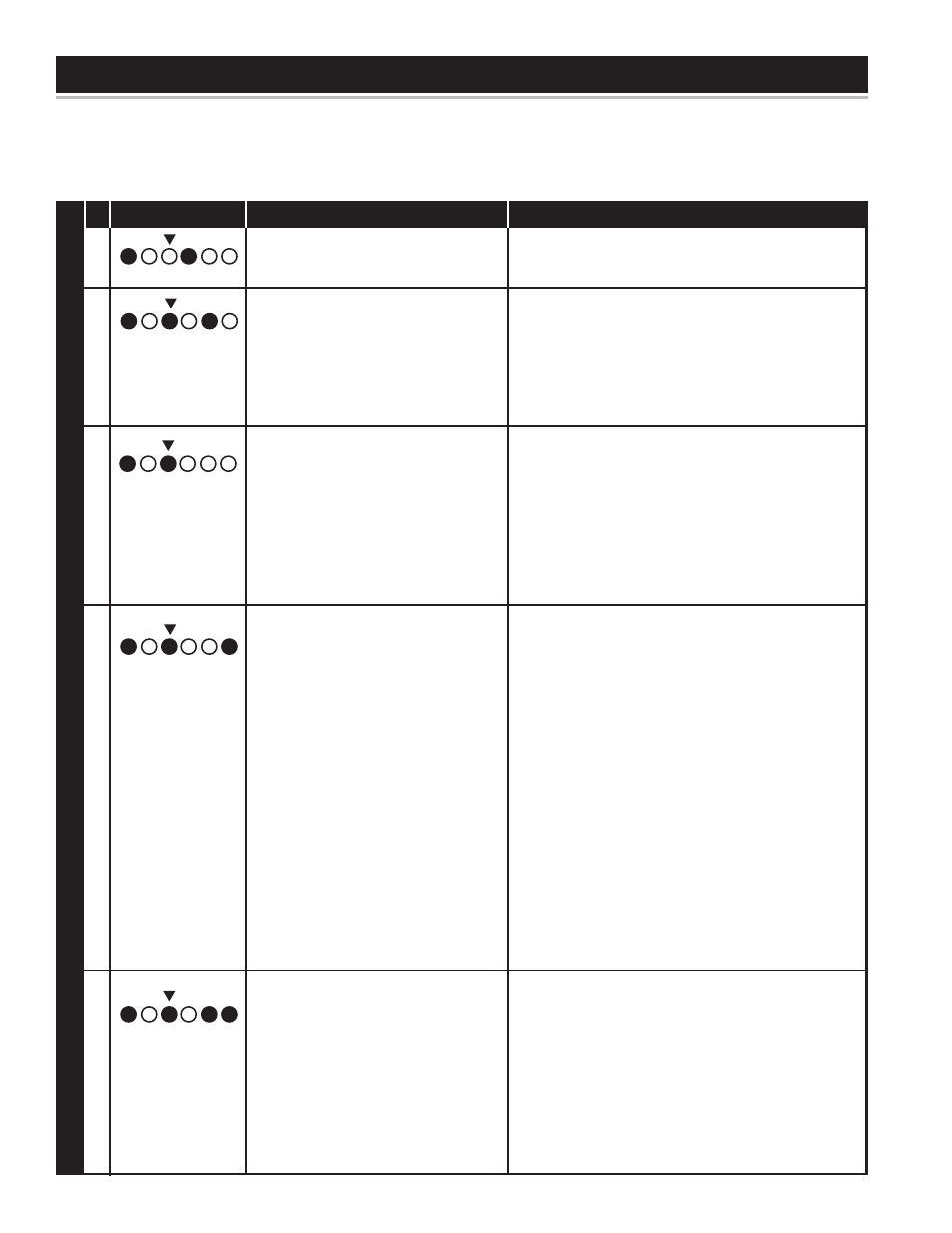

INTELLI-VENT TROUBLESHOOTING CHART - RESIDENTIAL CONTROL

proBleM

solutIon

Inadequate or no earth ground

1. Ensure the wall outlet is properly grounded.

1

sensed by the Intelli-Vent™

control.

2. Ensure all ground connections/wires on the

water heater are secure.

Power supply to Intelli-Vent™

1. Ensure the wall outlet is properly wired.

2

control has reversed polarity or a

high resistance to earth ground.

2. Ensure all internal 120 VAC wiring connections and

wiring harness have no reversed wires. 120 VAC

“hot” wire must connect to the on/off switch.

3. Ensure the wall outlet is properly grounded.

4. Ensure all ground connections/wires on the water

heater are secure.

Pressure switch circuit remaining

1. Ensure air pressure switch circuit wiring is correct

3

closed for more than 5 seconds

and the air pressure switch is not jumpered.

after heating cycle begins.

Blower does not start.

2. Secure power to water heater, check continuity of air

pressure switch contacts with wires disconnected.

service note:

Disconnect power - disconnect one

A If pressure switch contacts show continuity (closed

wire from the air pressure switch

circuit) replace the pressure switch.

or the vent temperature limit

switch. Turn power back on -

B If pressure switch contacts are open and all wiring

blower should start.

is correct - turn the power off for 10-20 seconds

then on again to clear the error code - if the error

code persists replace the Intelli-Vent™ control.

Pressure switch circuit remains open

1. Ensure the blower is running - check for 120 VAC to

4

longer than 5 seconds after the blower

the blower when the heating cycle begins, check the

is energized.

wiring. If the control does not energize the blower -

replace the Intelli-Vent™ control. If the blower fails to

Blower may run continuously in

start when energized - replace the blower assembly.

this condition.

2. Ensure the air pressure switch sensing tube is properly

connected - not kinked or damaged.

3. Check continuity of vent temperature limit switch - replace

switch if contacts remain open under 160ºF (71°C).

4. Ensure the correct size of vent pipe (2”, 3”, 4”) was used

per installation manual for vent length. Ensure maximum

number of elbows or equivalent feet of vent pipe has not

exceeded maximum limits.

5. Ensure there are no obstructions in the vent pipe.

6. Check air pressure switch performance - check pressure

with a digital manometer - check continuity of contacts.

(see service note in left column) If the switch proves

defective - replace the air pressure switch and or the

blower assembly as required.

7. If air pressure switch performance test results prove

the air pressure switch is working properly and error

code 4 persists - replace the Intelli-Vent™ control.

The Intelli-Vent™ control has detected

1. Check wiring to the hot surface ignitor - replace ignitor

5

an open ignitor circuit.

assembly if wiring is damaged or worn.

service note:

2. Check ignitor assembly plug and the socket on the

The resistance (ohms) of a hot surface

Intelli-Vent™ body for good connection. Replace

ignitor will increase over time. If the

ignitor assembly and/or control if necessary.

resistance at room temperature is near

18.8 ohms - consider replacing the ignitor 3. Check resistance of ignitor at room temperature 77ºF

as a preventative measure.

(25°C) at the plug end. Replace ignitor if resistance

is not within 11.5 and 18.8 ohms at room temperature.

4. If results from the above tests were good and error

code 5 persists - replace the Intelli-Vent™ control.

a B c

a B c

a B c

a B c

a B c

# led status

w

ater

hea

ter

control