John Wood Envirosense Power Vent User Manual

Page 15

15

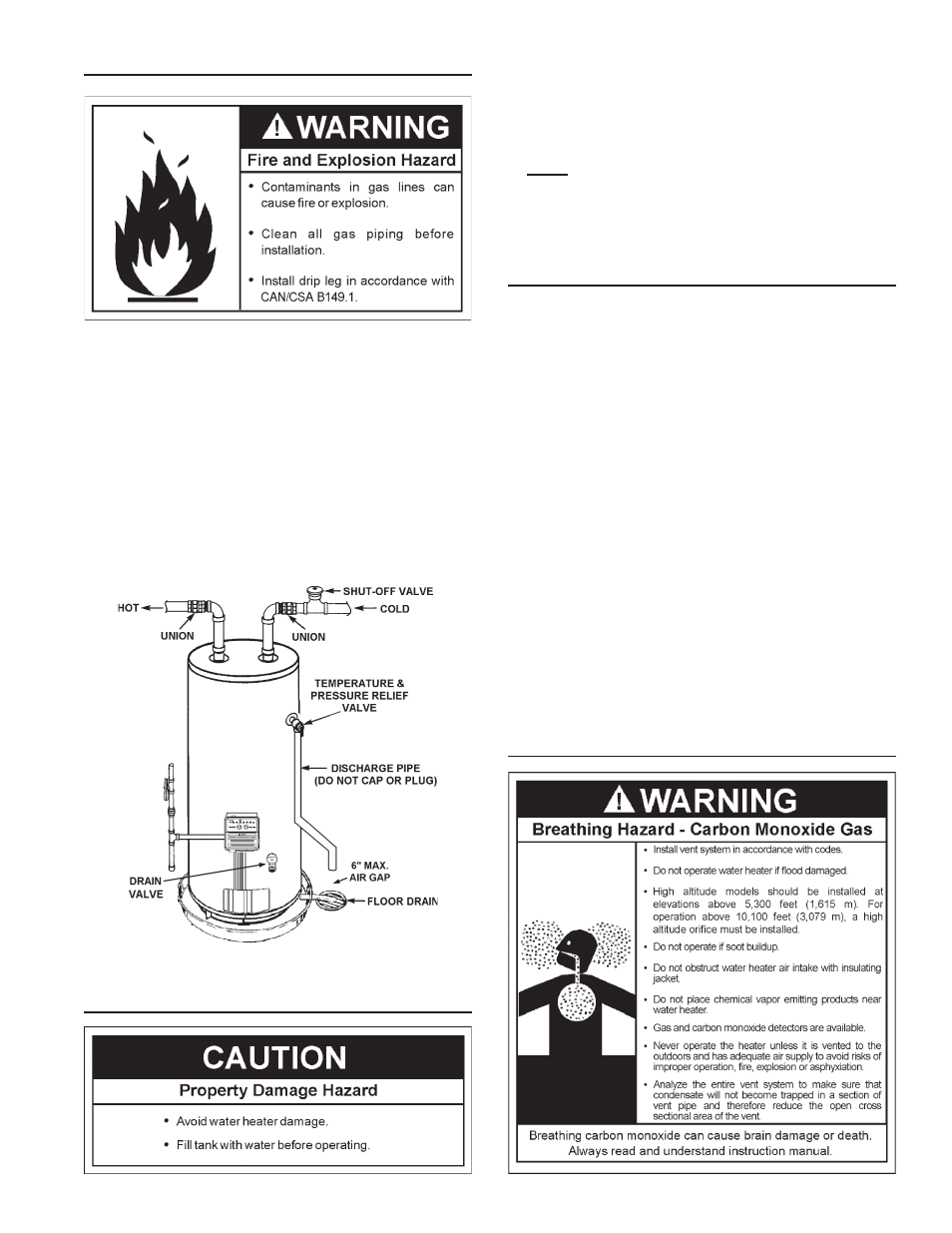

sedIMent traps

A sediment trap should be installed as close to the inlet of the water

heater as practical at the time of water heater installation. The

sediment trap should be either a tee fitting with a capped nipple

in the bottom outlet or other device recognized as an effective

sediment trap. If a tee fitting is used, it should be installed in

conformance with one of the methods of installation shown in

Figures 12 and 13.

Contaminants in the gas lines may cause improper operation of the

gas control valve that may result in fire or explosion. Before attaching

the gas line be sure that all gas pipe is clean on the inside. To trap any

dirt or foreign material in the gas supply line, a drip leg (sometimes

called a sediment trap) must be incorporated in the piping. The drip

leg must be readily accessible. Install in accordance with the “Gas

Piping” section. Refer to the current edition of the Natural Gas and

Propane Installation Code (CAN/CSA B149.1).

fIGure 14.

fIllInG the water heater

Never use this water heater unless it is completely full of water. To prevent

damage to the tank, the tank must be filled with water. Water must flow

from the hot water faucet before turning “ON” gas to the water heater.

To fill the water heater with water:

1. Close the water heater drain valve by turning the handle to the right

(clockwise). The drain valve is on the lower front of the water heater.

2. Open the cold water supply valve to the water heater.

note: the cold water supply valve must be left open when

the water heater is in use.

3. To insure complete filling of the tank, allow air to exit by opening the

nearest hot water faucet. Allow water to run until a constant flow is

obtained. This will let air out of the water heater and the piping.

4. Check all water piping and connections for leaks. Repair as needed.

vent pIpe asseMBlY

There are three parts of the vent pipe assembly that connect the water

heater exhaust (located on the lower back side of the water heater) to

the inlet of the blower assembly (mounted on top of the water heater) as

shown in Figure 1. These parts will need to be assembled according to

the instructions in the VENT PIPE PREPARATION section of this manual.

These PVC parts should be assembled with IPEX System 636 CPVC

Cement Product Code 196047.

Assemble Vent Pipe Assemblies #1, #2 and #3 (See Figure 1) prior

to cementing. The preferred orientation of Vent Pipe Assembly #1

(Condensate U-Assembly) is shown in Figure 16. However this

assembly may be rotated to a different orientation as needed for the

specific installation requirements. Note the rotational orientation of

each part by marking a line several inches long across the joints.The

long tube of Vent Pipe Assembly #2 should be approximately vertical.

If it is found that either of the two pieces of pipe in Vent Pipe Assembly

#2 are too long for proper fit-up, then remove as little material as

possible to improve the fit-up. Keep in mind that the pipes will insert

slightly further into the elbows when cement is applied as it acts as

a lubricating agent. The vertical distance from the bottom of the

Condensate U-Assembly to the floor that supports the water heater

should be approximately 0.25” (0.64 cm), see Figure 16. Disassemble

the parts and cement back together using the alignment marks. After

the cement dries, attach the assembly to the blower and the water

heater exhaust using the supplied rubber boots and hose clamps.

A condensate trap is incorporated in the bottom of this vent pipe

assembly. See the CONDENSATE section of this manual for

further details.

ventInG