Service instructions, Dealer servicing – Bell & Gossett P86109C Close Coupled Centrifugal Pumps User Manual

Page 6

SERVICE INSTRUCTIONS

1. Close valves on suction and discharge sides of pump. (If no

valves have been installed, it will be necessary to drain the

system.)

2. Remove motor foot capscrews. Loosen volute capscrews,

do not remove them. Use capscrews in the jack screw

holes. Start to remove the pump assembly from the volute.

3. Remove seal flushing tube, if used.

Remove the volute capscrews and remove the pump

assembly from the volute.

4. Remove the impeller capscrew, lock washer and washer.

Remove the impeller.

5. Remove the rotating portion of the seal, use a screwdriver

to loosen the rubber ring.

6. Remove the seal insert along with the insert gasket.

7. Thoroughly clean the shaft sleeve and the coverplate seal

cavity. Inspect for surface damage like pitting, corrosion,

nicks or scratches. Replace if necessary.

8. Lubricate the shaft sleeve and coverplate seal cavity with

soapy water. (Do not use petroleum lubricant.) Install a new

cup gasket and a new seal insert with indentation side

down into the cup.

9. Slide a new rotating seal assembly onto the shaft sleeve.

With a screwdriver push on the top of the compression ring

until the seal is tight against the seal insert. Install seal

spring.

10. Install impeller, impeller washer, lock washer and capscrew,

then tighten capscrew (per torque chart).

11. Install new volute gasket then install pump assembly into

volute. Tighten volute capscrews (per torque chart). Install

seal flushing tube, if used. Install motor foot capscrews and

tighten. Install drain plug, close drain valve.

12. Open isolation valves, inspect pump for leaks, if not leaking

return pump to service.

CAUTION: Extreme Temperature Hazard

Check surfaces for extreme temperatures, allow

pump temperatures to reach acceptable level before pro-

ceeding. Open drain valve, do not proceed until liquid stops

coming out of drain valve. If liquid does not stop flowing

from drain valve, isolation valves are not sealing and should

be repaired before proceeding. After liquid stops flowing

from drain valve leave drain valve open and continue.

Remove the drain plug located on the bottom of the pump

volute. Do not reinstall plug or close drain valve until

reassembly is completed.

Failure to follow these instructions could result in injury or

property damage.

WARNING: Unexpected Startup Hazard

Disconnect and lock out power before servicing.

Failure to follow these instructions could result in serious

personal injury or death.

CAUTION: Make certain the internal pressure is

relieved before continuing.

Failure to follow these instructions could result in injury or

property damage.

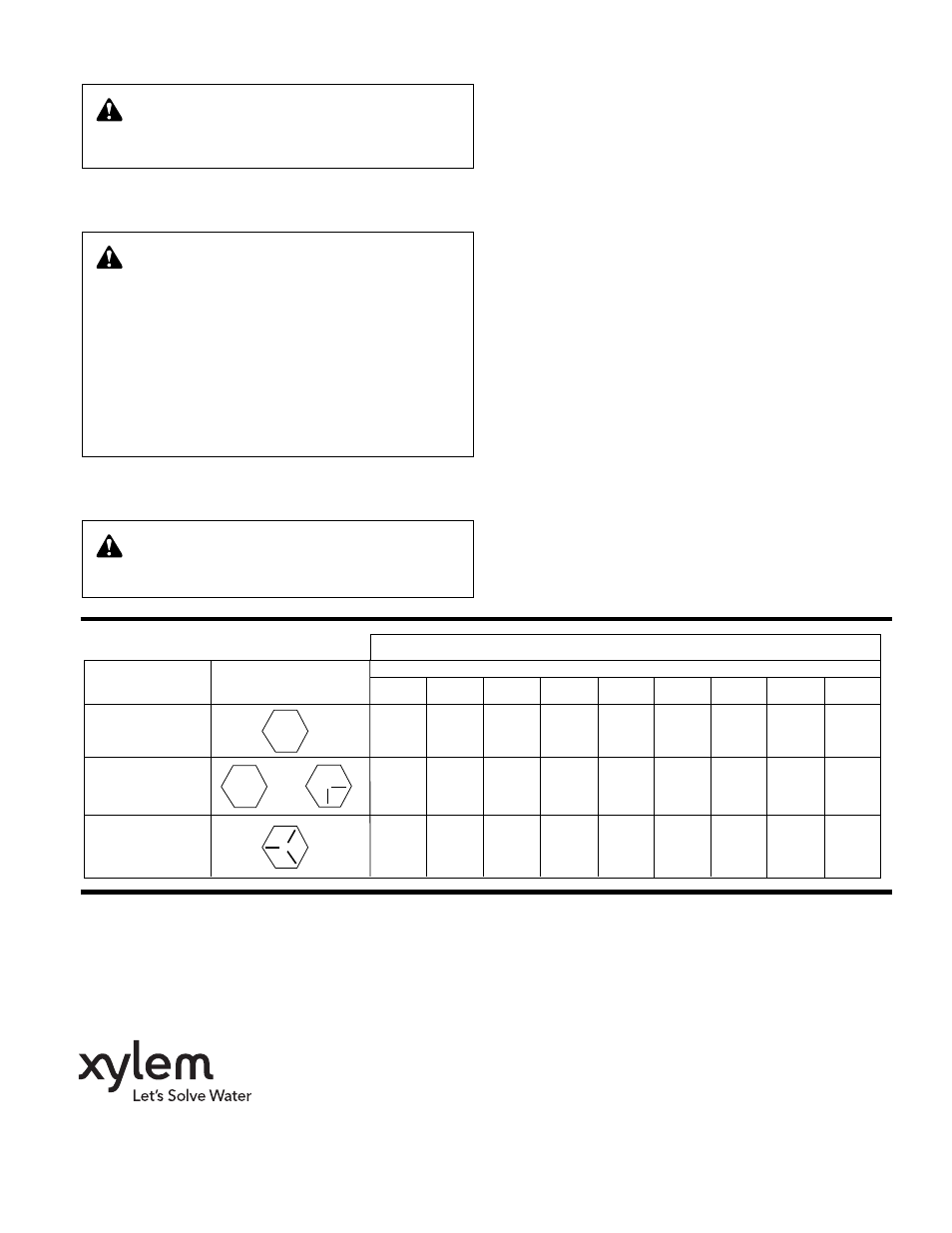

Capscrew

Head

Capscrew Diameter

Type

Marking

1

/

4

5

/

16

3

/

8

7

/

16

1

/

2

5

/

8

3

/

4

7

/

8

1

SAE Grade 2

6

13

25

38

60

20

190

210

300

Brass

4

10

17

27

42

83

130

200

300

Stainless Steel

or

SAE Grade 5

10

20

35

60

90

180

325

525

800

DEALER SERVICING

If trouble occurs that cannot be rectified contact your local

representative. He will need the following information in order to

give you assistance.

1. Complete nameplate data of pump and motor.

2. Suction and discharge pipe pressure gauge readings.

3. Ampere draw of the motor.

4. A sketch of the pump hook-up and piping.

CAPSCREW TORQUE (FOOT-POUND)

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. P86109C February 2013