Capscrew torque values, Dealer servicing, Capscrew torque values dealer servicing – Xylem P2000799B Series e-90 Close-Coupled In-Line Centrifugal Pumps User Manual

Page 20

4. Clean the motor and impeller threads. Apply Loctite 7471 Primer to the threads of the

motor and impeller. Allow to dry. Apply a small amount of Loctite Retaining

Compound 609 or 680 to the threads. Care must be used when applying Loctite so

that it does not get on surrounding areas.

5. Screw the impeller onto the motor shaft. Using a large screwdriver or an end wrench

and a strap wrench on the impeller OD, tighten the impeller to the motor shaft.

Torque the impeller to 20-25 ft-lbs. 25 ft-lbs can be approximated by turning the

impeller until the impeller hub is firmly against the motor shaft shoulder and then

turning an additional 15 degrees.

NOTE: On three phase motors it is very important to follow these instructions. Failure

to comply could allow the impeller to come loose during the motor rotation check if

the motor starts in reverse rotation.

6. Clean the bracket and volute gasket surfaces. Install a new gasket on the bracket.

7. Insert the motor assembly back into the pump casing. Tighten the casing capscrews

evenly.

8. Close the drain value and open the isolation valves. Inspect pump for leaks. If not

leaking, return pump to service. Reconnect the electrical service.

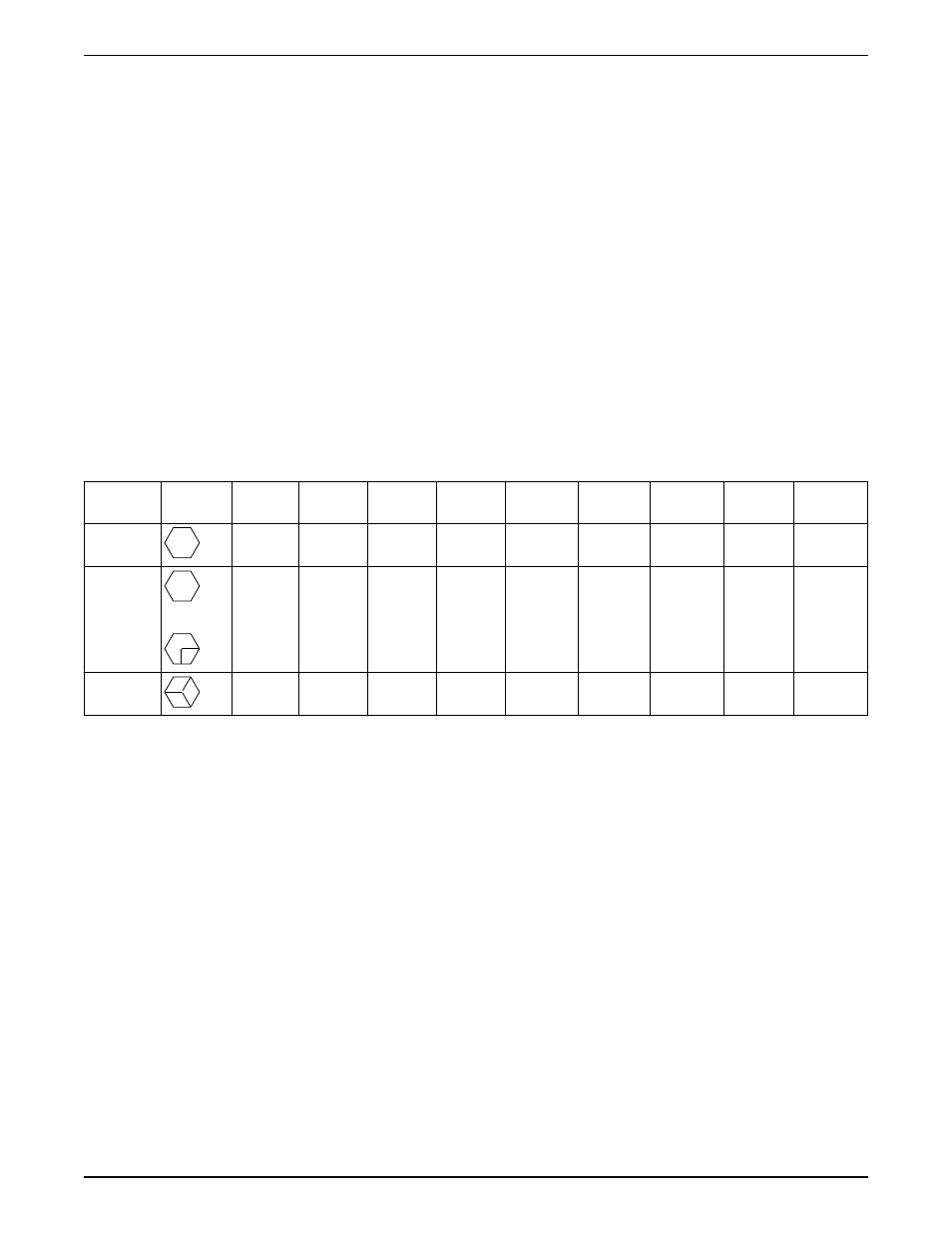

Capscrew torque values

Capscrew torque in ft-lbs (Nm)

Capscrew

type

Head

marking

1/4 in.

5/16 in.

3/8 in.

7/16 in.

1/2 in.

5/8 in.

3/4 in.

7/8 in.

1 in.

SAE grade 2

6 (8)

13 (18)

25 (34)

38 (52)

60 (81)

120 (163) 190 (258)

210 (285) 300 (407)

Brass or

stainless

steel

or

4 (5)

10 (14)

17 (23)

27 (37)

42 (57)

83 (113)

130 (176)

200 (271) 300 (407)

SAE grade 5

10 (14)

20 (27)

35 (47)

60 (81)

90 (122)

180 (244) 325 (441)

525 (712) 800 (1085)

Dealer servicing

If trouble occurs that cannot be rectified, contact your local sales and service

representative and be prepared to provide this information:

1. Complete nameplate data of pump and motor

2. Suction and discharge pipe pressure gauge readings

3. Ampere draw of the motor

4. A sketch of the pump hook-up and piping

Maintenance

18

Series e-90 Close-Coupled In-Line Centrifugal Pumps Installation, Operation, and Maintenance Manual