Pre-assembly inspections, Replacement guidelines, Reassembly – Xylem P2000799B Series e-90 Close-Coupled In-Line Centrifugal Pumps User Manual

Page 19: Reassemble the seal assembly

NOTICE:

These seal assemblies consist of a stationary seal insert assembly and a rotating seal

assembly. Each of these components must be replaced when you replace the

mechanical seal. Never replace individual components separately.

4. Grab the OD of the seal head assembly and remove. Remove the four capscrews that

hold the bracket to the motor and remove the bracket. Push the cup mounted seal

seat out of the bracket with a small screwdriver.

5. Clean the motor shaft and bracket recess with a clean lint free cloth.

Pre-assembly inspections

Guidelines

Before you assemble the pump parts, make sure you follow these guidelines:

• Inspect the pump parts according to the information in these pre-assembly topics

before you reassemble your pump. Replace any part that does not meet the required

criteria.

• Make sure that the parts are clean. Clean the pump parts in solvent in order to remove

oil, grease, and dirt.

NOTICE:

Protect machined surfaces while you clean the parts. Failure to do so may result in

equipment damage.

Replacement guidelines

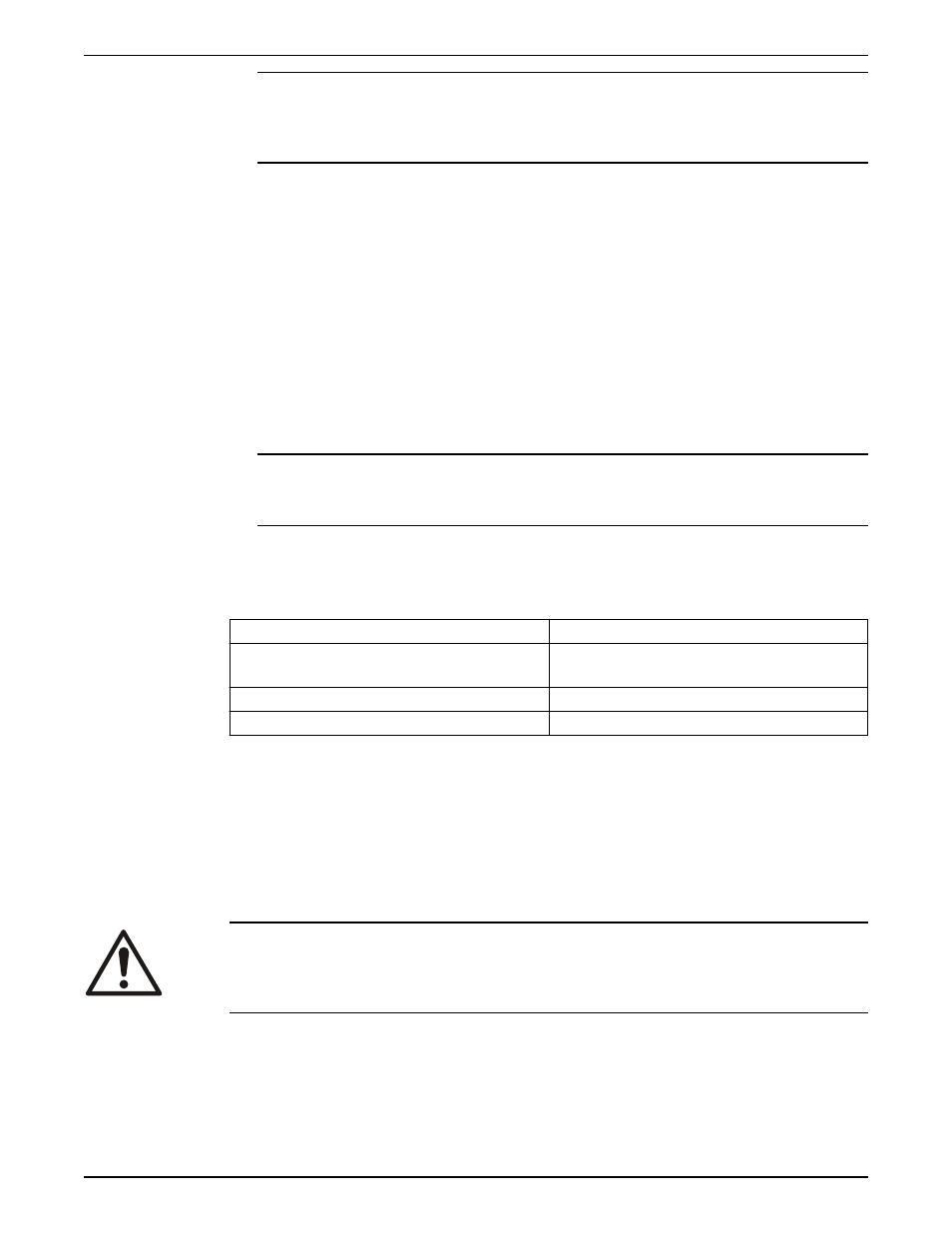

Impeller replacement

This table shows the criteria for replacing the impeller:

Impeller parts

When to replace

Impeller vanes

• When grooved deeper than 1/16 in. (1.6 mm), or

• When worn evenly more than 1/32 in. (0.8 mm)

Vane edges

When you see cracks, pitting, or corrosion damage

Impeller eye

When worn or grooved more than 1/16 in.(1.6 mm)

Gaskets, O-rings, and seal replacement

• Replace all gaskets and O-rings at each overhaul and disassembly.

• Inspect the seats. They must be smooth and free of physical defects.

• Replace parts if the seal faces or elastomer are damaged.

Reassembly

Reassemble the seal assembly

WARNING:

After you disassemble a gasket joint, always use a new gasket upon reassembly. Never

reuse old gaskets. Failure to follow these instructions can result in serious personal injury,

death, and/or property damage.

1. Lubricate the OD of the cup mounted seal seat with soapy water or P80 Rubber

Lubricant and push into the bracket.

2. Install the bracket onto the motor.

3. Check that the seal faces are clean. Lubricate the ID of the seal head assembly with

soapy water or P80 and push onto the motor shaft.

The seal head assembly is a unitized design and should not be disassembled.

Maintenance

Series e-90 Close-Coupled In-Line Centrifugal Pumps Installation, Operation, and Maintenance Manual

17