A-100nv, 2 input power connections, Page 5 typical installation – Xylem A-100NV DIGITAL PERISTALTIC PUMPS User Manual

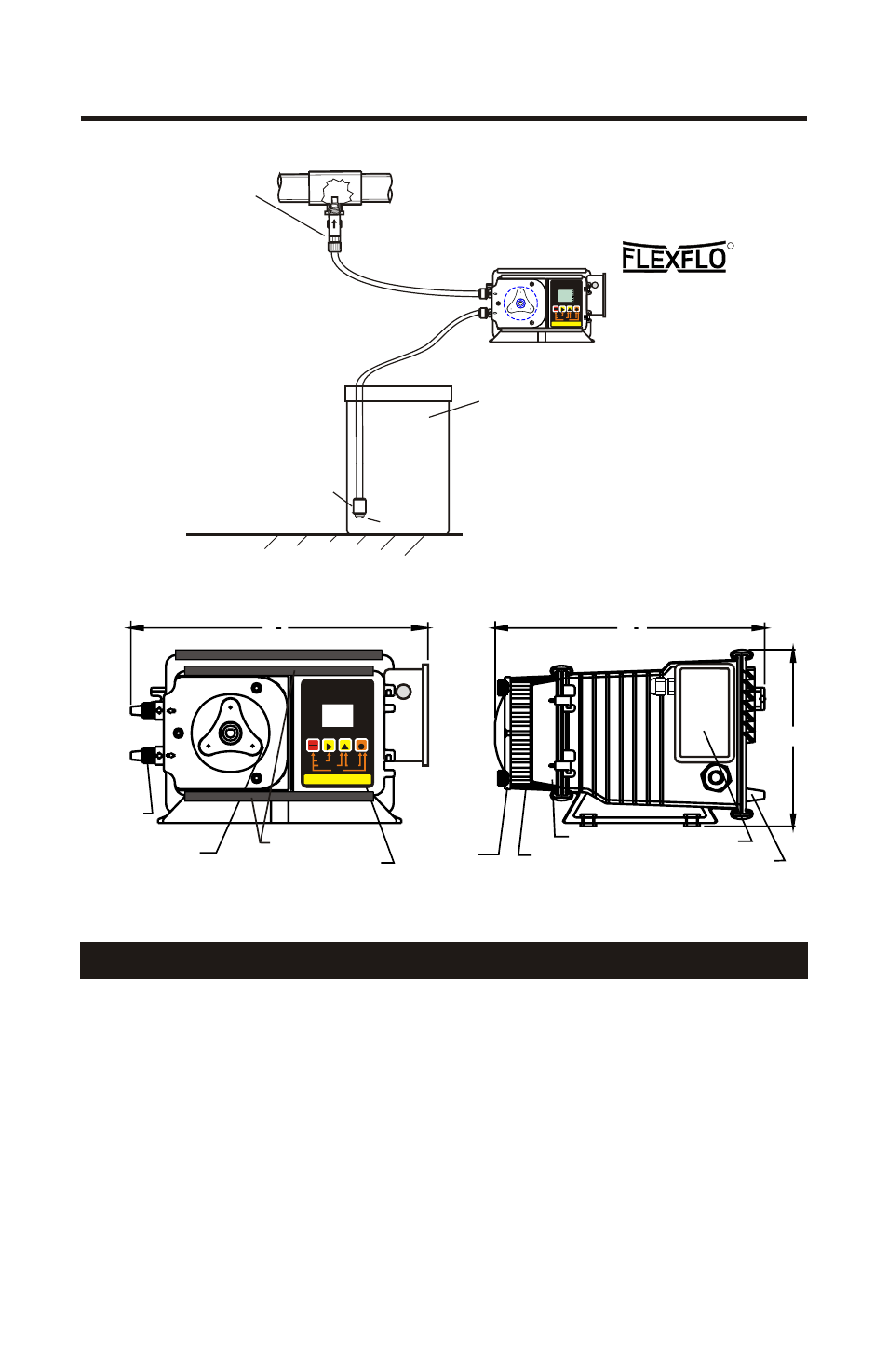

Page 5: Suction tube chemical container with cover, Parts locator drawing

Page 5

TYPICAL INSTALLATION

R

Suction

Tube

Chemical

Container

with cover

RUN

STANDBY

RUN

FIELD

DIGIT

MODE

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

INPUT MODES

1 - MANUAL

2 - 4-20mA

3 - 0-10VDC

4 - PULSE (Hz)

PROGRAM

RESET SERVICE

PRIME

DISPLAY

VARIABLE SPEED PUMP

% SPEED

1

MODE

VDC

SERVICE

1000

ALARM

mA

Hz

Discharge

Tube

Strainer

Ceramic Weight

Injection / Check valve

with 1/4” and 1/2” male

pipe threads.

Mount in upward position

to prevent trapped gasses

in the injection fitting.

Wall or shelf mount

away from the top of the

solution tank. Chemical

fumes can damage the

unit.

5.2 Input Power Connections

! Be certain to connect the pump to the proper supply voltage. Using the

incorrect voltage will damage the pump and may result in injury. The

voltage requirement is printed on the pump serial label.

! Jumper pins on the circuit board are factory preset for the correct voltage.

See page 7 Circuit Board Connections diagram for details.

! The pump is supplied with a ground wire conductor and a grounding type

attachment plug (power cord). To reduce the risk of electric shock, be

certain that the power cord is connected only to a properly grounded,

grounding type receptacle.

Note: When in doubt regarding your electrical installation, contact a

licensed electrician.

WARNING: Risk of electric shock.

WARNING: Risk of electric shock.

9

2

1

Control

Control Cover

Pumphead

Junction Box

Rear Plate

Pumphead

Cover

6.0

Pumptube

Assembly

Rotor

Assembly

9

8

1

Slide Clamps**

RUN

STANDBY

RUN

FIELD

DIGIT

MODE

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

INPUT MODES

1 - MANUAL

2 - 4-20mA

3 - 0-10VDC

4 - PULSE (Hz)

PROGRAM

RESET SERVICE

PRIME

DISPLAY

DIGITAL TIMER PUMP

PARTS LOCATOR DRAWING

A-100NV