F-1000, 6 how to install molded pvc tee fittings (te), 5 installing the molded in-line fitting (mi) – Xylem F1000 PADDLEWHEEL FLOW METERS User Manual

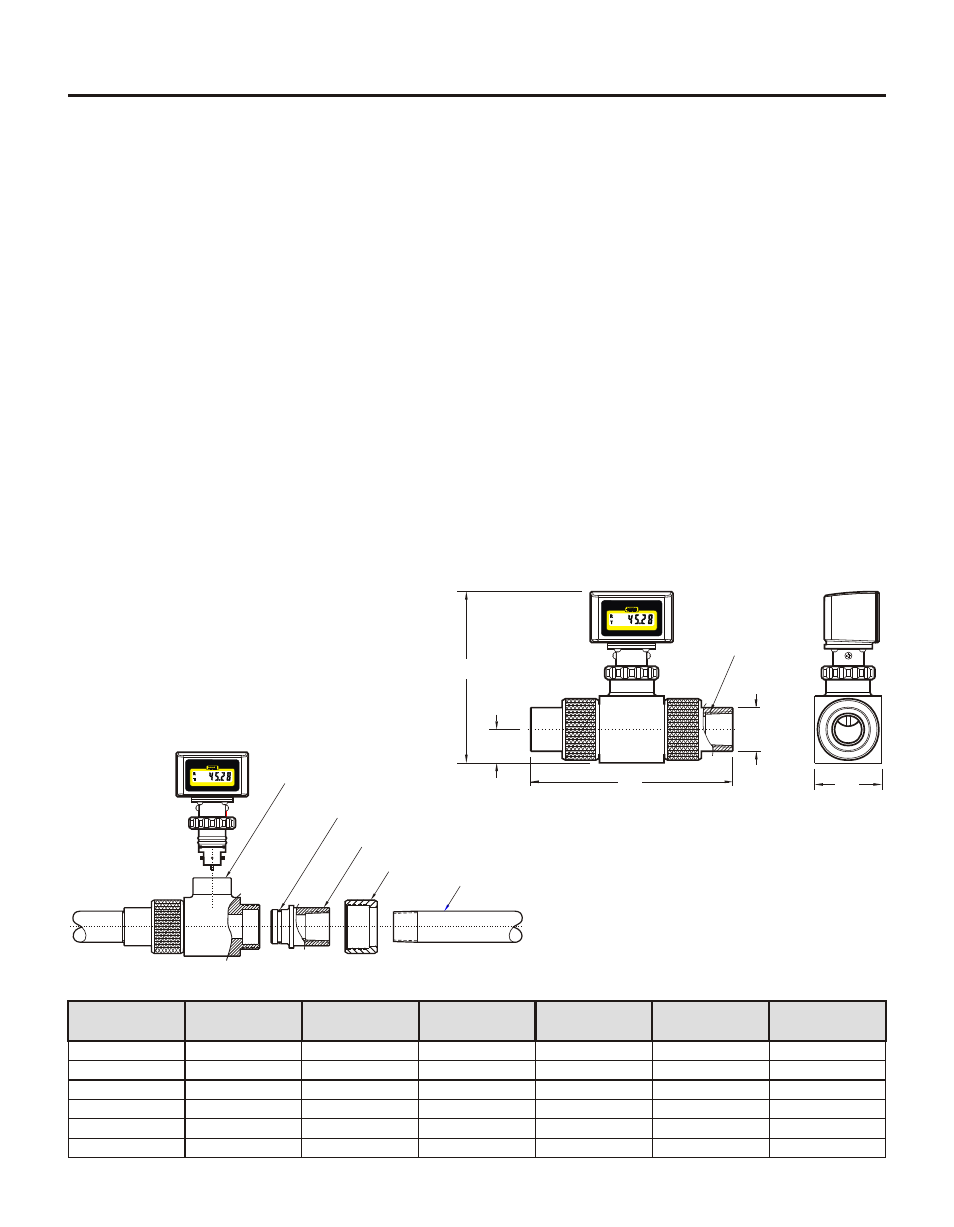

Page 8: Page 8, Page 9, Fig. 9, Fig. 11, Fig. 10, Dl k h w

Body Description

3/8” MPT-std flow

1/2” MPT-std flow

3/4” MPT-std flow

1.0” MPT-std flow

3/8” MPT-low flow

1/2” MPT-low flow

Length

L

4.73”

5.09”

5.25”

5.65”

4.73”

5.09”

3/4” MPT-low flow

1.0” MPT-low flow

5.25”

5.65”

4.4

INSTALLING THE F-1000 MACHINED IN-LINE FITTING (PI)

F-1000 machined in-line fittings consist of a meter body, two pipe adapter fittings (inlet and outlet), and two

half union nuts. Pipe adapters are supplied with female American National Standard Taper Pipe Threads (NPT).

The adapters are secured to the meter body with half union nuts and sealed with Viton O-rings.

Select an area on the pipe as outlined in section 4.1.

Install the F-1000 as you would any other plastic pipe fitting. Because the F-1000 uses half union nut style

connections, the adapters can be installed on the piping system first and then secured to the meter body with

the unions.

The F-1000 can be mounted on horizontal or vertical runs of pipe. Mounting at the twelve o'clock position

on horizontal pipe is recommended. Mounting anywhere around the diameter of vertical pipe is acceptable,

however, the pipe must be completely full of water at all times. See figure 4, 5 and 6.

Be sure the inlet and outlet fittings are aligned properly. Improper alignment of the fittings will put stress on

the adapter connections and may cause leaking or fitting damage.

Do not over tighten the fittings.

Use Teflon® tape sealant only on the adapter threads. Do not use pipe dope or glue.

Be sure the inlet and outlet plumbing is properly secured. The F-1000 is not designed to support the weight

of related piping. Improperly supported pipes will put stress on the adapter connections and may cause

leaking or fitting damage.

!

!

!

!

!

!

!

4.6

HOW TO INSTALL MOLDED PVC

TEE FITTINGS (TE)

Select an area on the pipe as outlined in section 4.1.

Remove the F-1000 sensor from the tee fitting. Do not glue the

TEE while the sensor is installed.

Install the F-1000 tee fitting as you would any other plastic

pipe solvent weld (glue) fitting. Do not use too much glue.

Excessive glue may create a disturbance in the flow stream

which will effect the accuracy of the meter.

The F-1000 can be mounted on horizontal or vertical runs of

pipe. Mounting at the twelve o'clock position on horizontal

pipe is recommended. Mounting anywhere around the diame-

ter of vertical pipe is acceptable, however, the pipe must be

completely full of water at all times. See figure 4, 5 and 6.

Install the F-1000 sensor. Be sure two O-rings are located on

the sensor body. The O-rings have been lubricated at the

factory with silicone oil. Push the sensor assembly into the

saddle with a twisting motion. The notch on the sensor body

must fit into the slot on the saddle. Be sure the sensor is fully

inserted into the saddle. HAND TIGHTEN the union nut.

!

!

!

!

!

F-1000

Page 8

F-1000

Page 9

F-1000-RT

Rate -

Totalizer

®

BLUE-WHITE INDUSTRIES

GALLONS PER MINUTE

Machined in-line body

O-ring

Machined adapter with FPT

Union nut

Pipe

Fig. 9

H

Nominal

Pipe Size

L

Fig. 11

Tee Fitting

Height

H

5.38”

5.38”

5.57”

5.57”

5.29”

5.29”

5.38”

5.57”

Nominal Pipe

Size

3/8”

1/2”

3/4”

1.0”

3/8”

1/2”

3/4”

1.0”

1”

4”

6”

1-1/2”

4-1/2”

6-5/8”

2”

4-3/4”

7-1/8”

Nominal Pipe

Size

Length

L

Height

H

Fig. 10

Molded in-line body

with M P T

Pipe

H

L

F-1000-RT

Rate -

Totalizer

®

BLUE-WHITE INDUSTRIES

GALLONS PER MINUTE

F/NPT - Female

Pipe Threads

D

L

K

H

W

F-1000-RT

Rate -

Totalizer

®

BLUE-WHITE INDUSTRIES

GALLONS PER MINUTE

F-1000-RT

Rate -

Totalizer

®

BLUE-WHITE INDUSTRIES

GALLONS PER MINUTE

4.5

INSTALLING THE MOLDED IN-LINE FITTING (MI)

All molded in-line (MI) fittings have male American National Standard Taper Pipe Threads (MPT).

Select an area on the pipe as outlined in section 4.1.

Install the F-1000 as you would any other plastic pipe fitting. Be sure the inlet and outlet fittings are aligned

properly. Improper alignment of the fittings will put stress on the adapter connections and may cause

leaking or fitting damage. Do not over tighten the fittings. Use Teflon® tape sealant only on the adapter

threads.

The F-1000 can be mounted on horizontal or vertical runs of pipe. Mounting at the twelve o'clock position

on horizontal pipe is recommended. Mounting anywhere around the diameter of vertical pipe is acceptable,

however, the pipe must be completely full of water at all times. See figure 4, 5 and 6.

Be sure the inlet and outlet plumbing is properly secured. The F-1000 is not designed to support the weight

of related piping. Improperly supported pipes will put stress on the adapter connections and may cause

leaking or fitting damage.

!

!

!

!

Nominal Pipe Size

3/8”

1

/2”

3/4”

1.0”

1-1/2”

2.0”

Pipe Threads

Size

3/8” - F/NPT

1

/2” - F/NPT

3/4” - F/NPT

1.0” - F/NPT

1-1/2” - F/NPT

2.0” - F/NPT

Overall Length

L

7.4” (188 mm)

7.4” (188 mm)

7.4” (188 mm)

7.4” (188 mm)

9.4” (239 mm)

11.4” (290 mm)

Overall Height

H

6.3” (159 mm)

6.3” (159 mm)

6.3” (159 mm)

6.3” (159 mm)

6.6” (167 mm)

7.1” (180 mm)

Center Height

K

1.22 “ (31 mm)

1.22 “ (31 mm)

1.22 “ (31 mm)

1.22 “ (31 mm)

1.70” (43 mm)

2.00” (51 mm)

Adapter O.D.

D

1.60” (40.6 mm)

1.60” (40.6 mm)

1.60” (40.6 mm)

1.60” (40.6 mm)

2.50” (63.5 mm)

3.08” (78.2 mm)

Body Width

W

2.45” (62 mm)

2.45” (62 mm)

2.45” (62 mm)

2.45” (62 mm)

2.5” (63 mm)

3.0” (76 mm)