F-1000, 0 flow ranges, Ips pipes – Xylem F1000 PADDLEWHEEL FLOW METERS User Manual

Page 10: Metric pipes, Page 10, Page 11, F-1000 circuit board, Saddles - standard flow [min - max

5.0

HOW TO OPERATE THE F-1000

Note:

The calibrated units of measure such as GPM, LPM, M3H, GALLONS, LITERS, CUBIC METERS, ect., And the decimal

point location are pre-programmed at the factory to standard flow ranges (see chart). Any unit of measure can be factory programmed.

Please contact the factory for details.

! The meter is shipped from the factory with 2 AAA batteries installed.

! When measuring continuous flow (i.e. 24 hours per day, 7 days per week), do not operate the meter in the upper 25% of the

calibrated flow range. The paddle speed in these high flow ranges is fast. Damage to the paddle may occur if the meter is

allowed to run continuously at the high flow rate, especially with corrosive or abrasive fluids.

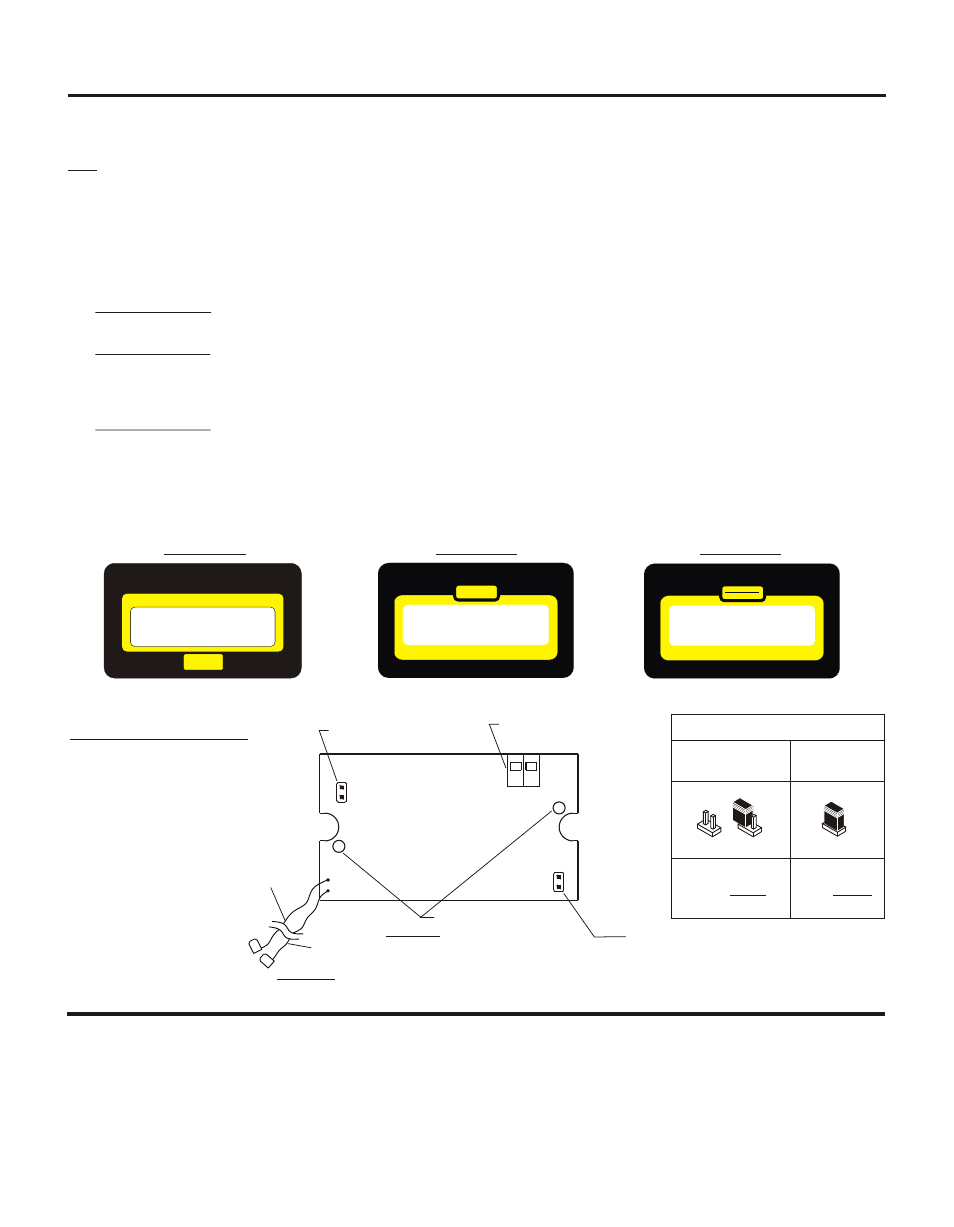

Model F-1000-RB:The F-1000-RB is the basic rate meter. The meter will display the rate of flow from .01 through 999999 in

any engineering units. Some standard units of measure are GPM, GPH, GPD, LPM, LPH, LPD, M3H, etc.

Model F-1000-TB:The F-1000-TB is the basic totalizer meter. The meter will display the total flow amounts from .01 through

999999 in any engineering units. Some standard units of measure are GALLONS, LITERS, CUBIC METERS. Pressing and

holding the RESET button (located on the front panel) for at least 2.0 seconds resets the total to zero. This feature can be

disabled -- see Fig. 12 below.

Model F-1000-RT:The F-1000-RT is the rate and totalizer meter. The meter will display the flow rate amounts and the total flow

amounts from .01 through 999999 in any engineering units. Some standard units of measure are GALLONS PER MINUTE,

GALLONS PER HOUR, GALLONS PER DAY, LITERS PER MINUTE, LITERS PER HOUR, LITERS PER DAY, CUBIC

METERS PER HOUR, CUBIC METERS PER DAY. Pressing the RESET button (located on the front panel) toggles the display

between flow rate and total flow. Pressing and holding the RESET button for at least 2.0 seconds while the total flow value is

displayed will reset the total to zero. This feature can be disabled -- see Fig. 12 below.

!

!

!

F-1000

Page 10

F-1000

Page 11

2

1

-

+

Red wire

(Positive lead)

Black wire

(Negative lead)

Terminal blocks

(AC Coil sensor input)

Jumpers

(Front Panel Totalizer Reset

Enable/Disable)

Header pins

(Tail membrane connector)

Battery size: two AAA (1.5 V each)

Screw size: #4 x .50 Philip oval “A”

Mounting holes (x2)

Fig. 12

F-1000-RT

Rate -

Totalizer

®

BLUE-WHITE INDUSTRIES

RESET

MODE

®

BLUE-WHITE INDUSTRIES

F-1000-RB

Flow Rate Meter

GPM

GALLONS PER MINUTE

F-1000-TB

Flow Totalizer

®

BLUE-WHITE INDUSTRIES

RESET

GALLONS

F-1000-RB

F-1000-TB

F-1000-RT

F-1000 Circuit Board

Jumper Not

Installed (open)

Jumper

Installed

JUMPER CONFIGURATION

Total flow reset

to zero Enable

(Factory default)

Total flow reset

to zero Disable

!

The F-1000 is factory calibrated to ± 2% of full scale rate reading. When measuring total flow, accumulated error

over time must be considered. Accuracy is based on laboratory testing of nominal pipe dimensions. Your actual

accuracy will vary based on your actual pipe I.D. And other installation factors.

!

Due to increased wear on the paddle and axle, continuous operation at the upper 25% of the flow range is not

recommended.

6.0 FLOW RANGES

MACHINED INLINE BODIES - Standard Flow Range #1 [ Min - Max]

2.00 - 20.00

Pipe Size

3/8” INLINE

1 /2” INLINE

3/4” INLINE

1.0” INLINE

1-1/2” INLINE

2.0” INLINE

GPM 1

48.0 - 480.0

.800 - 8.000

4.00 - 40.00

6.00 - 60.00

15.0 - 150.0

30.0 - 300.0

GPH 1

120 - 1200

360 - 3600

900 - 9000

1800 - 18000

GPD 1

1100 - 11000

2800 - 28000

5700 - 57000

8600 - 86000

21500 - 215000

43000 - 430000

240 - 2400

LPM 1

180 - 1800

3.00 - 30.00

7.00 - 70.00

15.0 - 150.0

25.0 - 250.0

60.0 - 600.0

100 - 1000

LPH 1

420 - 4200

900 - 9000

1500 - 15000

3600 - 36000

6000 - 60000

M3H 1

0.180 - 1.800

0.420 - 4.200

0.900 - 9.000

1.50 - 15.00

3.60 - 36.00

6.00 - 60.00

SADDLES - Standard Flow [Min - Max]

Pipe Size

1-1/2” IPS

2.0” IPS

3.0” IPS

4.0” IPS

6.0” IPS

8.0” IPS

GPM 1

15.0 - 150.0

30.0 - 300.0

60.0 - 600.0

100 - 1000

250 - 2500

400 - 4000

GPH 1

900 - 9000

1800 - 18000

3600 - 36000

6000 - 60000

15000 - 150000

24000 - 240000

GPD 1

21500 - 215000

43000 - 430000

86500 - 865000

144000 - 999999

360000 - 999999

575000 - 999999

10.0” IPS

12.0” IPS

600 - 6000

800 - 8000

36000 - 360000

48000 - 480000

865000 - 999999

N/A

LPM 1

60.0 - 600.0

100 - 1000

250 - 2500

400 - 4000

900 - 9000

1500 - 15000

LPH 1

3600 - 36000

6000 - 60000

15000 - 150000

24000 - 240000

54000 - 540000

90000 - 900000

M3H 1

6.00 - 60.00

15.0 - 150.0

24.0 - 240.0

54.0 - 540.0

90.0 - 900.0

2200 - 22000

3000 - 30000

132000 - 999999

180000 - 999999

132 - 1320

180 - 1800

MACHINED INLINE BODIES - Low Flow Range #2 [Min - Max]

.500 - 5.000

Pipe Size

3/8” INLINE

1 /2” INLINE

3/4” INLINE

1.0” INLINE

1-1/2” INLINE

2.0” INLINE

GPM 2

20.0 - 200.0

.400 - 4.000

.800 - 8.000

2.00 - 20.00

10.0 - 100.0

15.0 - 150.0

GPH 2

30.00 - 300.0

120 - 1200

600 - 6000

900 - 9000

GPD 2

550 - 5500

700 - 7000

1100 - 11000

2800 - 28000

14400 - 144000

21500 - 215000

48.0 - 480.0

LPM 2

60.0 - 600.0

1.00 - 10.00

2.00 - 20.00

3.00 - 30.00

7.00 - 70.00

40.0 - 400.0

60.0 - 600.0

LPH 2

120 - 1200

180 - 1800

420 - 4200

2400 - 24000

3600 - 36000

M3H 2

0.060 - 0.600

0.120 - 1.200

0.180 - 1.800

0.420 - 4.200

2.40 - 24.00

3.60 - 36.00

MACHINED INLINE BODIES - Low Flow Ranges #3, 4, 5, and 6 [Min - Max]

-

Pipe Size

3/8” INLINE

1 /2” INLINE

3/4” INLINE

1.0” INLINE

1-1/2” INLINE

2.0” INLINE

GPM 3

-

-

-

-

6.00 - 60.00

10.0 - 100.0

GPM 4

-

-

2.00 - 20.00

6.00 - 60.00

GPM 5

-

-

-

-

1.00 - 10.00

4.00 - 40.00

-

GPM 6

-

-

-

-

-

2.00 - 20.00

-

LPM 3

-

-

-

25.0 - 250.0

40.0 - 400.0

-

LPM 4

-

-

7.00 - 70.00

25.0 - 250.0

-

LPM 5

-

-

-

-

4.00 - 40.00

15.0 - 150.0

LPM 6

-

-

-

-

-

7.00 - 70.00

IPS PIPES

MOLDED INLINE BODIES - Standard Flow Range #1 [Min - Max]

2.00 - 20.00

Pipe Size

3/8” INLINE

1 /2” INLINE

3/4” INLINE

1.0” INLINE

GPM 1

48.0 - 480.0

.800 - 8.000

3.00 - 30.00

5.00 - 50.00

GPH 1

120 - 1200

300 - 3000

GPD 1

1100 - 11000

2800 - 28000

4320 - 43200

7200 - 72000

180 - 1800

LPM 1

180 - 1800

3.00 - 30.00

7.00 - 70.00

11.0 - 110.0

20.0 - 200.0

LPH 1

420 - 4200

660 - 6600

1200 - 12000

M3H 1

0.180 - 1.800

0.420 - 4.200

0.660 - 6.600

1.20 - 12.00

MOLDED INLINE BODIES - Low Flow Range #2 [Min - Max]

.500 - 5.000

Pipe Size

3/8” INLINE

1 /2” INLINE

3/4” INLINE

1.0” INLINE

GPM 2

20.0 - 200.0

.400 - 4.000

.800 - 8.000

2.00 - 20.00

GPH 2

30.00 - 300.0

120 - 1200

GPD 2

550 - 5500

700 - 7000

1100 - 11000

2800 - 28000

48.0 - 480.0

LPM 2

60.0 - 600.0

1.00 - 10.00

2.00 - 20.00

3.00 - 30.00

7.00 - 70.00

LPH 2

120 - 1200

180 - 1800

420 - 4200

M3H 2

0.060 - 0.600

0.120 - 1.200

0.180 - 1.800

0.420 - 4.200

METRIC PIPES

Pipe Size

50 MM - PN 10 & PN 16

63 MM - PN 10 & PN 16

90 MM - PN 10 & PN 16

110 MM - PN 10 & PN 16

160 MM - PN 10 & PN 16

200 MM - PN 10 & PN 16

LPM 1

4200 - 42000

70.0 - 700.0

110 - 1100

230 - 2300

350 - 3500

720 - 7200

1150 - 11500

LPH 1

6600 - 66000

13800 - 138000

21000 - 210000

43000 - 430000

70000 - 700000

M3H 1

4.20 - 42.00

6.60 - 66.00

13.8 - 138.0

21.0 - 210.0

43.0 - 430.0

70.0 - 700.0

SADDLES - Standard Flow [Min - Max]

160 MM - PN 10

200 MM - PN 10

1700 - 17000

2700 - 27000

100000 - 1000000

170000 - 1700000

100 - 1000

170 - 1700

(Meet ASTM-D-1785)

(Meet DIN 8062)