Xylem F1000 PADDLEWHEEL FLOW METERS User Manual

Page 2

F-1000-RT

Rate -

Totalizer

®

BLUE-WHITE INDUSTRIES

GALLONS PER MINUTE

1.0

INTRODUCTION TO THE F-1000

Congratulations on purchasing the F-1000 electronic flow meter. The F-1000 is designed to measure the flow

of a fluid in a pipe. The meter is factory calibrated to any engineering units and displays the rate of flow or the

total of flow on a 6 digit LCD display. Two AAA batteries power the unit for up to one year. There are three

models are available:

F-1000-RB is a rate meter - designed to measure and display the rate of flow.

F-1000-TB is a totalizer meter - designed to measure and display the total flow.

F-1000-RT is a rate/totalizer meter - designed to measure and display both the rate of flow and the total flow.

3. FEATURES

Easy to read .35" high, six digit LCD display.

Weather resistant enclosure.

Installs quickly on existing pipe.

Corrosion resistant PVDF sensor, ABS

Factory calibrated -nothing to program.

enclosure.

Minimal maintenance required.

High accuracy.

No pressure drop.

Large calibrated flow range.

!

!

!

!

!

!

!

!

!

F-1000

Page 2

F-1000

Page 3

2.0

SPECIFICATIONS

Maximum Working Pressure*

300 psig / 20.7 bar

o

o

Maximum Fluid Temperature*

200 F / 93.3 C -Saddle and sensor only

o

o

200 F / 93.3 C -When mounted on polypropylene and PVDF inline units.

o

o

140 F / 60 C -When mounted on molded PVC tee units or PVC pipe.

o

o

o

o

Ambient Temperature Range

32 to 110 F / 0 to 43 C

Enclosure

NEMA 4X (acceptable for outdoor use)

NOTE: Protect the LCD display from direct sunlight.

Accuracy

+/-2% of full scale rate reading

Repeatability

+/-1% of full scale rate reading

Power Requirements

Two standard AAA alkaline batteries (included)

Battery Life Expectancy

1 year minimum

*Temperature vs. Pressure

PSIg (BAR)

PSIg (BAR)

Temperature

Temperature

When mounted on

Molded PVC Tee or PVC pipe units

150°F (65.5°C)

175°F (79.4°C)

200°F (93.3°C)

125°F (51.6°C)

100°F (37.8°C)

70°F (21.1°C)

0 (0)

60 (4.1)

120 (8.3)

180 (12.4)

240 (16.5)

300 (20.7)

When mounted on

Polypropylene and PVDF inline units or PVDF Saddles

140°F (60°C)

120°F (48.9°C)

100°F (37.8°C)

70°F (21.1°C)

Fig. 2

TABLE OF CONTENTS

SECTION

HEADING

PAGE

1

Introduction

2

2

Specifications

3

3

F-1000 Features

3

4

How to install the F-1000

4

4.1

Mounting location

4

4.2

Pipe Flow Stream Requirements

4

4.3

How to install Your F-1000 Saddle Fitting

6

4.3.1

Drill the Mounting Hole

7

4.3.2

Install the Saddle

7

4.3.3

Check the Saddle Alignment

7

4.3.4

Install the F-1000 Sensor

7

4.4

Installing the F-1000 Machined In-Line Fitting (PI)

8

4.5

Installing the Molded In-Line Fitting (MI)

9

4.6

How to Install Molded PVC Tee Fitting

9

5

How to Operate the F-1000

10

6

F-1000 Flow Ranges

11

7

How to Maintain the F-1000

12

8

Troubleshooting

12

9

Replacement Parts List

13 - 15

*Pressure and temperature limits are inversely proportional.

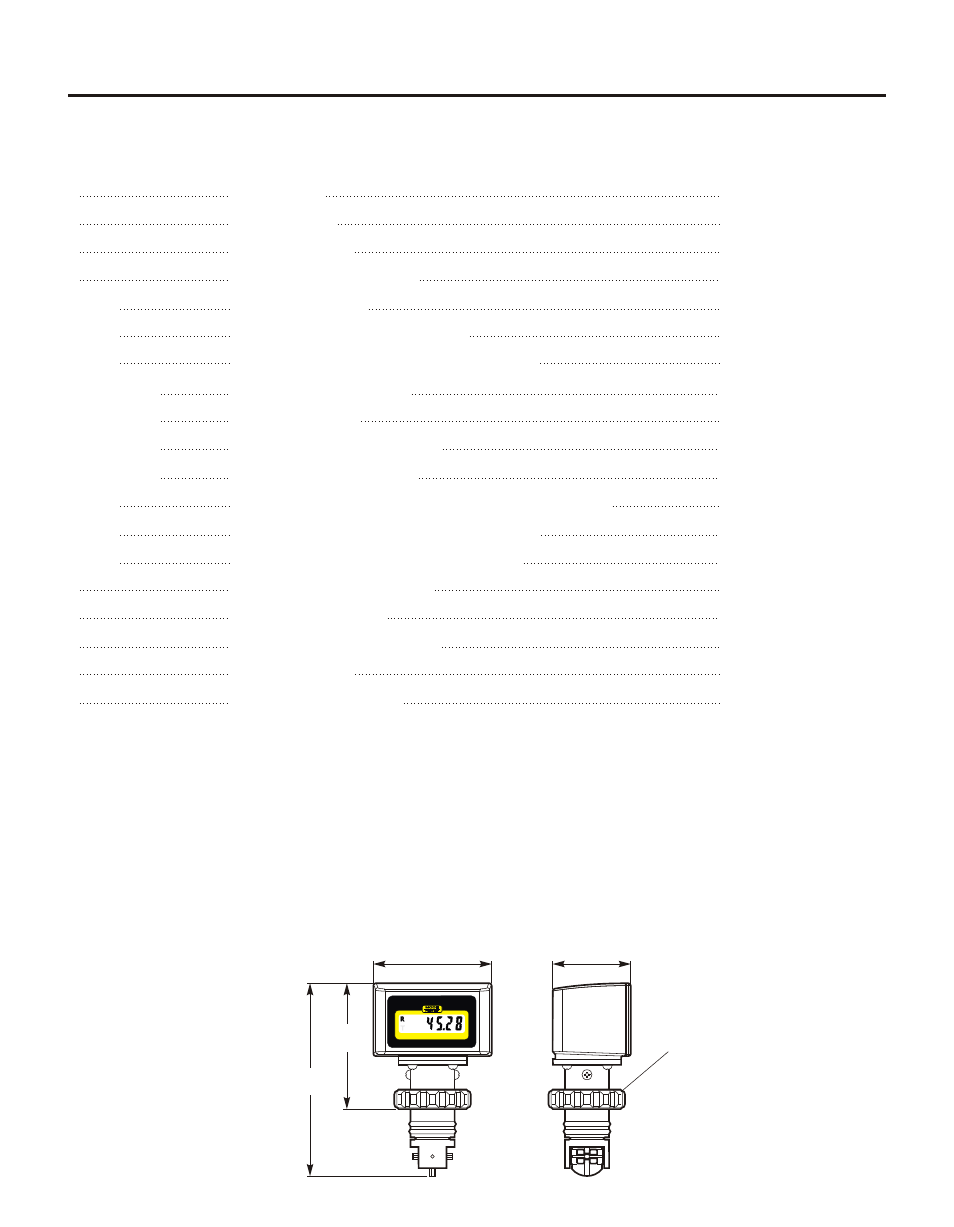

3.03 in.

(77 mm)

2.00 in.

(50.8 mm)

Fig. 1

3.10 in.

(78.7 mm)

Union Nut

4.93 in.

(125.2 mm)

0 (0)

60 (4.1)

120 (8.3)

180 (12.4)

240 (16.5)

300 (20.7)