F-1000, 1 drill the mounting hole, 2 install the saddle – Xylem F1000 PADDLEWHEEL FLOW METERS User Manual

Page 6: 3 check the saddle alignment

108

4.3

HOW TO INSTALL YOUR F-1000 SADDLE FITTING

The F-1000 saddle is designed to mount on smooth schedule 40 IPS pipe, schedule 80 IPS pipe (ASTM-D-

1785) , PN10 metric pipe or PN16 metric pipe (DIN 8062). The outside of the pipe must be clean, smooth and

free of surface imperfections. The outside diameter must be as specified to ensure a leak free installation. The

inside diameter must be as specified to ensure meter accuracy.

4.3.1 DRILL THE MOUNTING HOLE

Select an area on the pipe as outlined in section 4.1. Be sure the surface area of the pipe is clean and

smooth.

Drill a 1-1/8" diameter hole through the center of the pipe wall. On horizontal installations, drill the hole as

close to the 12 O'clock position as possible. A hole saw kit is available from the factory, order part number

20000-062.

Clean all burrs from inside and outside the hole. Use fine sandpaper (440 grit) if necessary.

4.3.2 INSTALL THE SADDLE

Insert the alignment tool through the top of the saddle. Proper alignment is critical! Slide the large O-ring

over the bottom of the alignment tool and into the groove on the underside of the saddle.

With the alignment tool and O-ring in place, position the saddle over the drilled hole. Insert the alignment

tool into the hole seating the saddle. Be sure the O-ring is properly seated in the O-ring groove.

Place the pipe clamps around the pipe and into the slots on the saddle. Tighten the clamps in an alternating

method.

!

!

!

!

!

!

4.3.3 CHECK THE SADDLE ALIGNMENT

Pull the alignment tool out of the saddle. (If the tool is not easily removed, slightly loosen the clamps)

Inspect the hole. The saddle must be mounted directly over the hole. Adjust the saddle alignment until the

alignment tool slides freely in and out of the saddle.

Be certain the O-ring is properly seated and visible in the groove around the hole.

Tighten the clamps.

4.3.4 INSTALL THE F-1000 SENSOR

Be sure two O-rings are located on the sensor body. The O-rings have been lubricated at the factory with

silicone oil.

Push the sensor assembly into the saddle with a twisting motion. The notch on the sensor body must fit into

the slot on the saddle. Be sure the sensor is fully inserted into the saddle.

HAND TIGHTEN the union nut

.

!

!

!

!

!

!

F-1000

Page 6

F-1000

Page 7

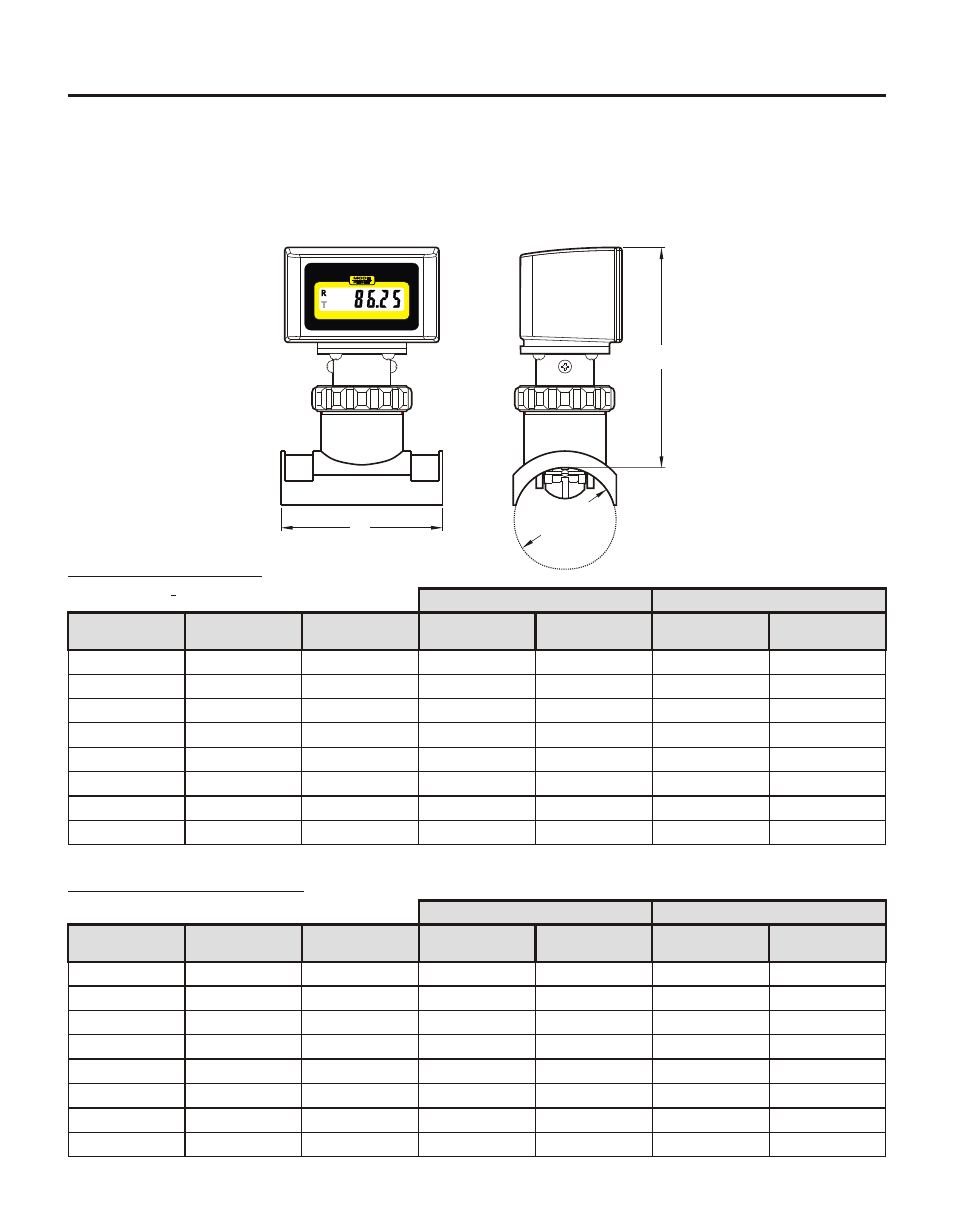

PIPE O.D.

(

Outside Diameter)

H

Fig. 7

See Chart

on Page 4

See Chart

on Page 4

Alignment

Tool

Saddle

Sensor Body

O-rings

Union Nut

Hose Clamps

In. Diameter On Center

FLOW

I.D.

Drill Hole 1.125±

Saddle O-ring

.030

.000

Fig. 8

Center Line

Metric Pipe Sizes (in millimeters)

I.P.S. Pipe Sizes (in inches)

Nominal Pipe

Size

1-1/2”

2”

3”

4”

6”

8”

Length

3-3/16”

3-3/16”

3-3/16”

3-3/16”

3-3/16”

3-3/16”

Height

4-5/16”

4-5/16”

4-5/16”

4-5/16”

4-1/4”

4-1/4”

Outside

Diameter

1.900

2.375

3.500

4.500

6.625

8.625

Inside

Diameter

1.610

2.067

3.068

4.026

6.065

7.981

Outside

Diameter

1.900

2.375

3.500

4.500

6.625

8.625

Inside

Diameter

1.500

1.939

2.900

3.826

5.761

7.625

Schedule 40

Schedule 80

Nominal Pipe

Size

50 mm

63 mm

90 mm

110 mm

160 mm

Length

81

81

81

81

81

Height

110

110

110

110

108

Outside

Diameter

50.0

63.0

90.0

110.0

160.0

Inside

Diameter

45.2

57.0

81.4

99.4

144.6

Outside

Diameter

50.0

63.0

90.0

110.0

160.0

Inside

Diameter

42.6

53.6

76.6

93.6

136.2

Pn10

Pn16

(ASTM-D-1785)

(DIN 8062)

200 mm

81

200.0

180.8

200.0

170.2

O-ring

Saddle

Pipe

Alignment

Tool

L

F-1000-RT

Rate -

Totalizer

®

BLUE-WHITE INDUSTRIES

GALLONS PER MINUTE

F-1000-RT

Rate -

Totalizer

®

BLUE-WHITE INDUSTRIES

GALLONS PER MINUTE

10”

12”

4-1/2”

4-1/2”

4-1/4”

4-1/4”

10.750

12.750

10.020

11.938

10.750

12.750

9.564

11.376

108

250 mm

114

108

250.0

226.2

N/A

N/A

315 mm

114

315.0

285.0

N/A

N/A