Safety instructions, Typical installation, Danger – Xylem IM182 Balanced Flow User Manual

Page 3

3

1: SAFETY INSTRUCTIONS

TO AVOID SERIOUS OR FATAL PERSONAL INJURY

OR MAJOR PROPERTY DAMAGE, READ AND

FOLLOW ALL SAFETY INSTRUCTIONS IN MANUAL

AND ON EQUIPMENT.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT AND

MUST BE KEPT WITH THE UNIT.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump,

the controller or in the manual, look for

one of the following signal words and

be alert to the potential for personal

injury or property damage.

Warns of hazards that WILL cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause serious

personal injury, death or major property

damage.

Warns of hazards that CAN cause

personal injury or property damage.

NOTICE:

INDICATES SPECIAL

INSTRUCTIONS WHICH ARE

VERY IMPORTANT AND MUST BE

FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS

AND WARNINGS PRIOR TO PERFORMING ANY

WORK ON THIS CONTROLLER.

MAINTAIN ALL SAFETY DECALS.

DANGER

WARNING

CAUTION

This controller is not designed for use

around swimming pools, open bodies of

water, hazardous liquids, or where flammable gases exist.

Do not use GFCI input power. This will

cause nuisance faults.

Disconnect and lockout electrical power

before installing or servicing any

electrical equipment.

ELECTROCUTION HAZARD.

CONTROLLER INPUT GROUND

TERMINAL (GND) AND ALL EXPOSED METAL

PIPING, INCLUDING PRESSURE TRANSDUCER

CASE, MUST BE CONNECTED TO THE SERVICE

ENTRANCE GROUND TERMINAL.

All electrical work must be performed

by a qualified technician. Always follow

the National Electrical Code (NEC), or the Canadian

Electrical Code, as well as all local, state and provincial

codes. Code questions should be directed to your local

electrical inspector. Failure to follow electrical codes and

OSHA safety standards may result in personal injury or

equipment damage. Failure to follow manufacturer’s

installation instructions may result in electrical shock,

fire hazard, personal injury or death, damaged

equipment, unsatisfactory performance, and may void

manufacturer’s warranty.

NOTICE: Some installations pull a vacuum on the

transducer when the system is drained. The new controller

is designed to protect against up to 17” Hg. of vacuum

on the transducer. An optional Gauge Guard, order

no. 6K210, will protect the transducer from a vacuum

condition.

WARNING

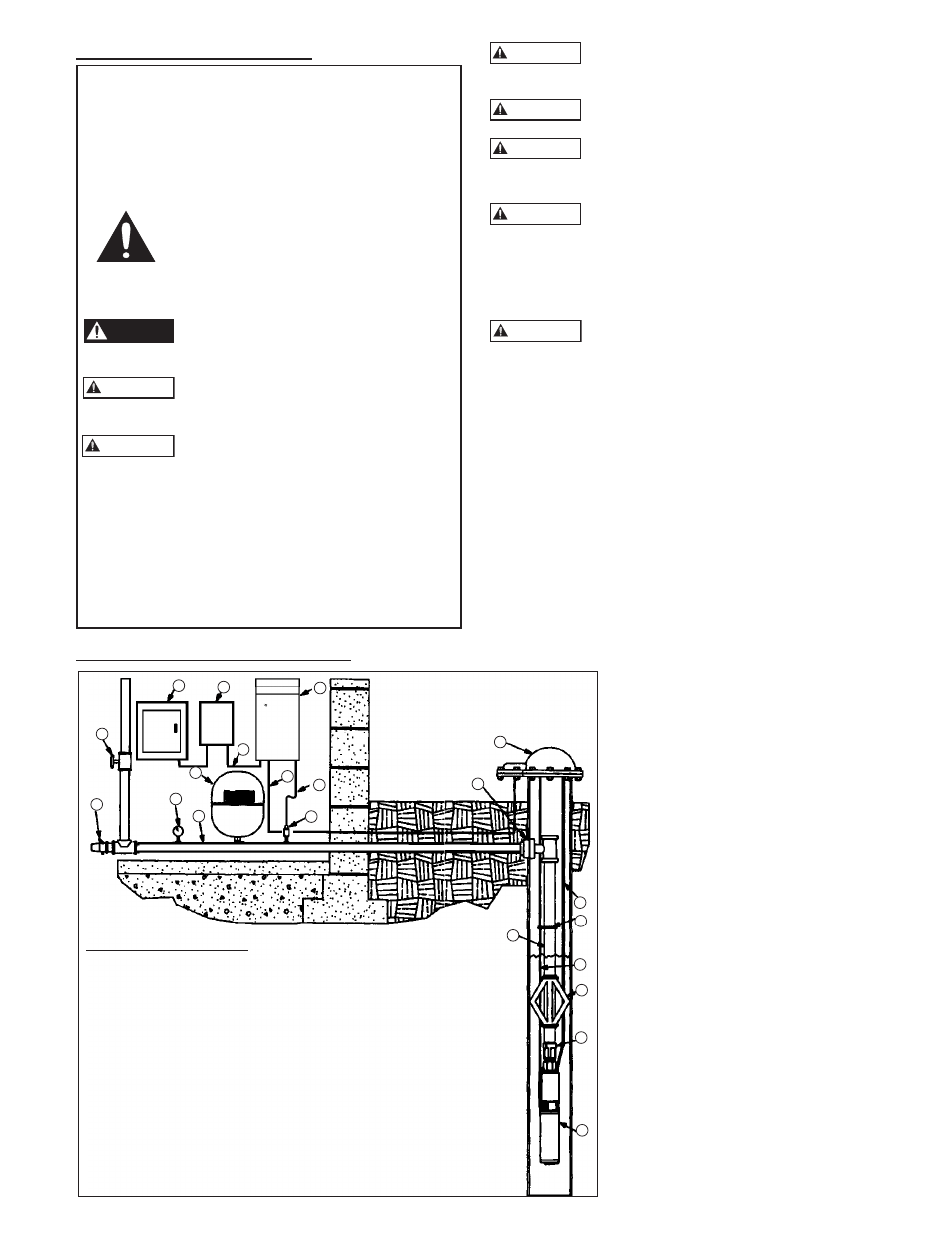

PARTS DESCRIPTION:

1) Pump and Motor

10) Power Supply Cable

2) Check Valve (built-in

11) Service Entrance

on some models)

12) Pressure Sensor Cable

3) Torque Arrestor (optional)

with drip loop

4) Pump Power Cable

13) Diaphragm Tank

with Splice Kit

14) Pressure Transducer

5) Electrical Tape

15) Pressure Gauge

(Cable to Pipe)

16) Relief Valve

6) Safety Rope (optional)

17) Shut-Off Valve

7) Well Cap / Seal

18) Drop Pipe

8) Pitless Adapter

19) Lateral Pipe

9) Controller

20) Electrical Disconnect

17

16

9

15

11

10

12

13

14

4

8

7

6

5

4

3

2

1

TYPICAL INSTALLATION

TYPICAL INSTALLATION

18

19

20

WARNING

WARNING

WARNING

1: SAFETY INSTRUCTIONS

WARNING