Xylem IM244R04 SPD Plus Variable Speed Pump Control User Manual

Page 16

16

SECTION 6: POWER SUPPLY AND WIRING

(CONTINUED)

CONDUIT, WIRE AND FUSE SIZING

When selecting the input power cable follow the rules

below:

• Do not use aluminum wires

• The cable must be able to carry the drive load

current

• The cable must be rated for at least 75ºC

• A four conductor cable (three phases and ground)

or four insulated conductors routed through

conduit may be used. Shielding is not required.

The use of metal conduit with metal conduit

connectors is recommended for all electrical

connections. Use the NEC or CEC to determine

the required conduit size for the application.

Refer to the wire sizing tables in Appendix B to

determine the maximum length for the input and

output cables. The maximum recommended total

voltage drop on both input and output cable

combined is 5%. Standard wire sizing table provides

maximum cable lengths for input or output cables.

Because of this the lengths given in the table must be

adjusted so the total voltage drop does not exceed

5%. For example, if the input wire sizing chart in the

appendix gives the maximum length of 400' and

only 100' is used then only 25% of the total voltage

drop (1.25% drop) is used. The maximum output

cable length must then be adjusted to 75% of its

value so that the maximum voltage drop of 5% is not

exceeded.

Provide a dedicated fused disconnect rated for drives

input current rating. (Fused disconnect included for

NEMA3R enclosures.) No other equipment should be

used for this disconnect. Use fast acting class T fuses.

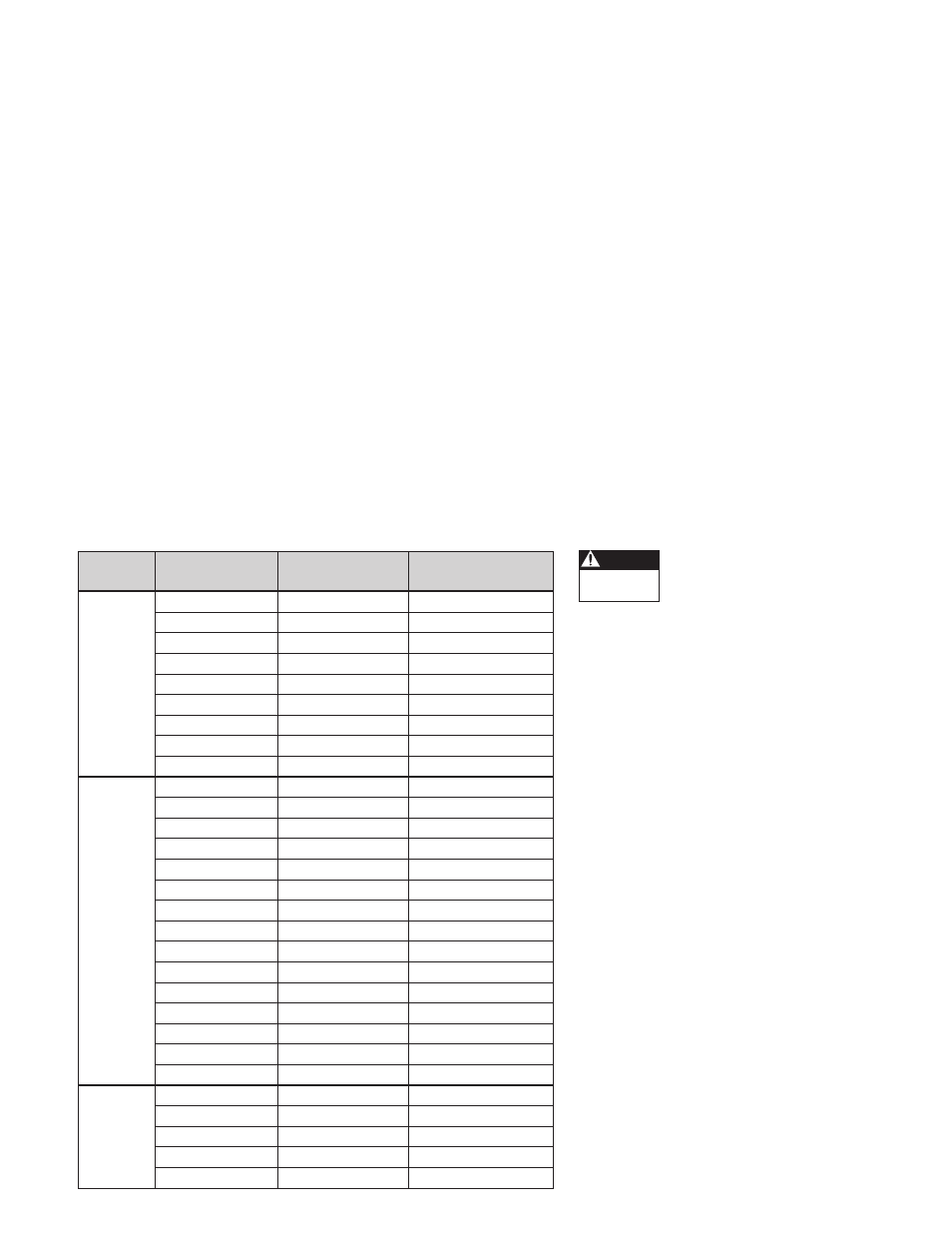

The recommended fuse sizes for each model are

listed below.

INPUT POWER CONNECTIONS

Before making this connection, measure and verify

the site voltage phase to phase and phase to ground.

In the case of high line to ground voltage it may be

necessary to disconnect the line to ground EMC and

MOV protection. See Figures 1, 2 and 3 for details.

Ensure the ground wire is connected back to the

service entrance ground and that the service entrance

ground is bonded to a proper ground rod.

Ensure disconnect switches

are locked in the OFF

position before making this

connection. For models with an N1 (NEMA

1) suffix, connect conduit to the conduit

box supplied with the controller. For all

other models (NEMA 3R), drill a hole that

is properly sized for the conduit used in

the bottom of the enclosure.

NOTE: Drilling in to the side or top of the

enclosure will violate the NEMA 3R rating.

Use metal conduit and metal conduit

connectors. Size the conduits according to

the NEC, CEC or local codes. Use the wire

sizing chart in Appendix B to determine

the size of the input power wires.

Connect the conduit and insert the wires

into the controller or enclosure. Connect

wires to the “INPUT” terminal block. For

N1 models, this terminal block is on the

controller and the terminal locations are

as shown in Figures 1, 2 and 3. For all

other models, this connection is made

to the input side of the fused disconnect

that is included in the enclosure. The

connections from the output side of the

disconnect to the controller are made at

the factory. Connect the ground wire to

the terminal labeled GND. For three phase

input, connect the input phase wires to

U1, V1 and W1. For single phase input,

connect the input wires to U1 and W1.

Input

Voltage

Model Number

Input Current

(Arms)

Mains Fuse Size

(UL Class T)

230V

SPD20400

114

150

SPD20400F

143

200

SPD20400N1

114

150

SPD20500

143

200

SPD20500F

178

250

SPD20500N1

143

200

SPD20600

178

250

SPD20600F

221

300

SPD20600N1

178

250

460V

SPD40400

59

80

SPD40400F

72

90

SPD40400N1

59

80

SPD40500

72

90

SPD40500F

96

125

SPD40500N1

72

90

SPD40600

96

125

SPD40600F

96

125

SPD40600N1

96

125

SPD40750

124

175

SPD40750F

124

175

SPD40750N1

124

175

SPD41000

157

200

SPD41000F

157

200

SPD41000N1

157

200

575V

SPD50400N1

52

60

SPD50500N1

77

100

SPD50600N1

77

100

SPD50750N1

99

150

SPD51000N1

144

200

Hazardous

voltage

DANGER