Motor insulation resistance readings, Troubleshooting – Xylem IM045 R03 High Head Effluent Pumps User Manual

Page 5

5

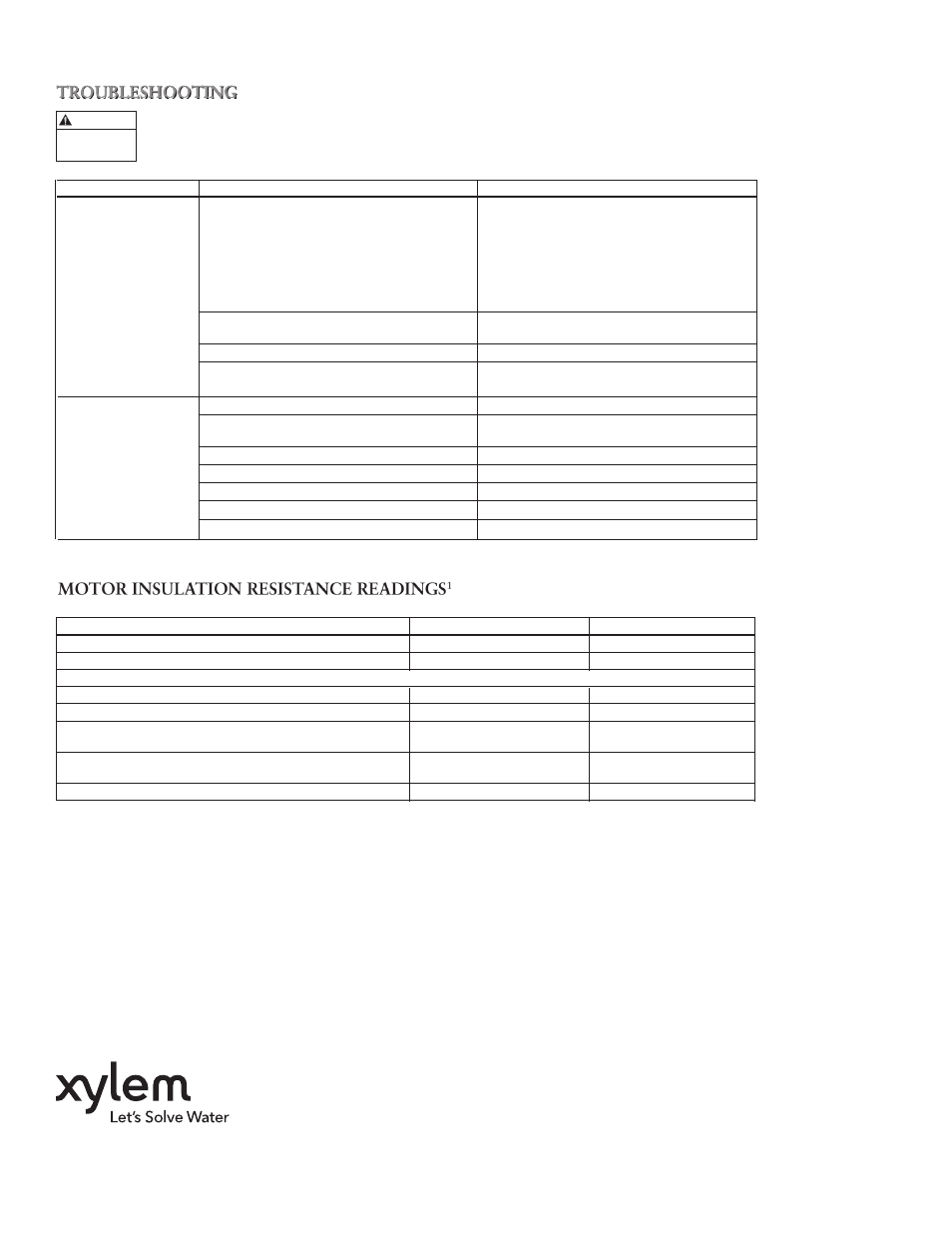

MOTOR INSULATION RESISTANCE READINGS

1

Condition of Motor and Leads

OHM Value

Megohm Value

New motor, without power cable

20,000,000 (or more)

20.0

Used motor, which can be reinstalled in tank

10,000,000 (or more)

10.0

Motor in tank – Readings are power cable plus motor

New motor

2,000,000 (or more)

2.0

Motor in reasonably good condition

500,000 to 2,000,000

0.5 – 2.0

Motor which may be damaged or have damaged power cable

20,000 to 500,000

0.02 – 0.5

Do not pull motor for these reasons

Motor definitely damaged or with damaged power cable

10,000 to 20,000

0.01 – 0.02

Pull motor and repair

Failed motor or power cable – Pull motor and repair

Less than 10,000

0 – 0.01

1

Courtesy of Franklin Electric Company

WARNING

Hazardous

voltage

TROUBLESHOOTING

DISCONNECT AND LOCKOUT ELECTRICAL POWER BEFORE ATTEMPTING

ANY SERVICE. FAILURE TO DO SO CAN CAUSE SHOCK, BURNS OR DEATH.

Symptom

Probable Cause

Recommended Action

PUMP MOTOR

NOT RUNNING

LITTLE OR NO LIQUID

DELIVERED BY PUMP

1. Motor thermal protector tripped

a.

Incorrect or faulty electrical connections

b. Faulty thermal protector

c.

Low voltage

d. Pump bound by foreign matter

e.

Inadequate submergence

1. Allow motor to cool, thermal protector will

automatically reset.

a-e. Have a qualified electrician inspect and

repair, as required.

f.

Pull pump, clean, adjust set depth

as required.

g. Confirm adequate unit submergence

in pumpage.

2. Open circuit breaker or blown fuse

2. Have a qualified electrician inspect and repair,

as required

3. Power source inadequate for load

3. Check supply or generator capacity

4. Power cable insulation damage

5. Faulty power cable splice

4. & 5. Have a qualified electrician inspect and

repair, as required

1. Faulty or incorrectly installed check valve

2. Pump air bound

3. Lift too high for pump

4. Pump bound by foreign matter

5. Pump not fully submerged

6. Filter/screen plugged

7. Excessive pump wear

1. Inspect check valve, repair as required

2. Successively start and stop pump until flow is

delivered

3. Review unit performance, check with dealer

4. Pull pump, clean, adjust set depth as required

5. Check float settings, lower pump if possible

6. Clean filter

7. Pull pump and repair as required

Xylem, Inc.

www.completewatersystems.com

© 2012 Xylem Inc. IM045 Revision Number 3 July 2012