Bell & Gossett 6 71 075 115A LS Condensate Removal Pump User Manual

Page 4

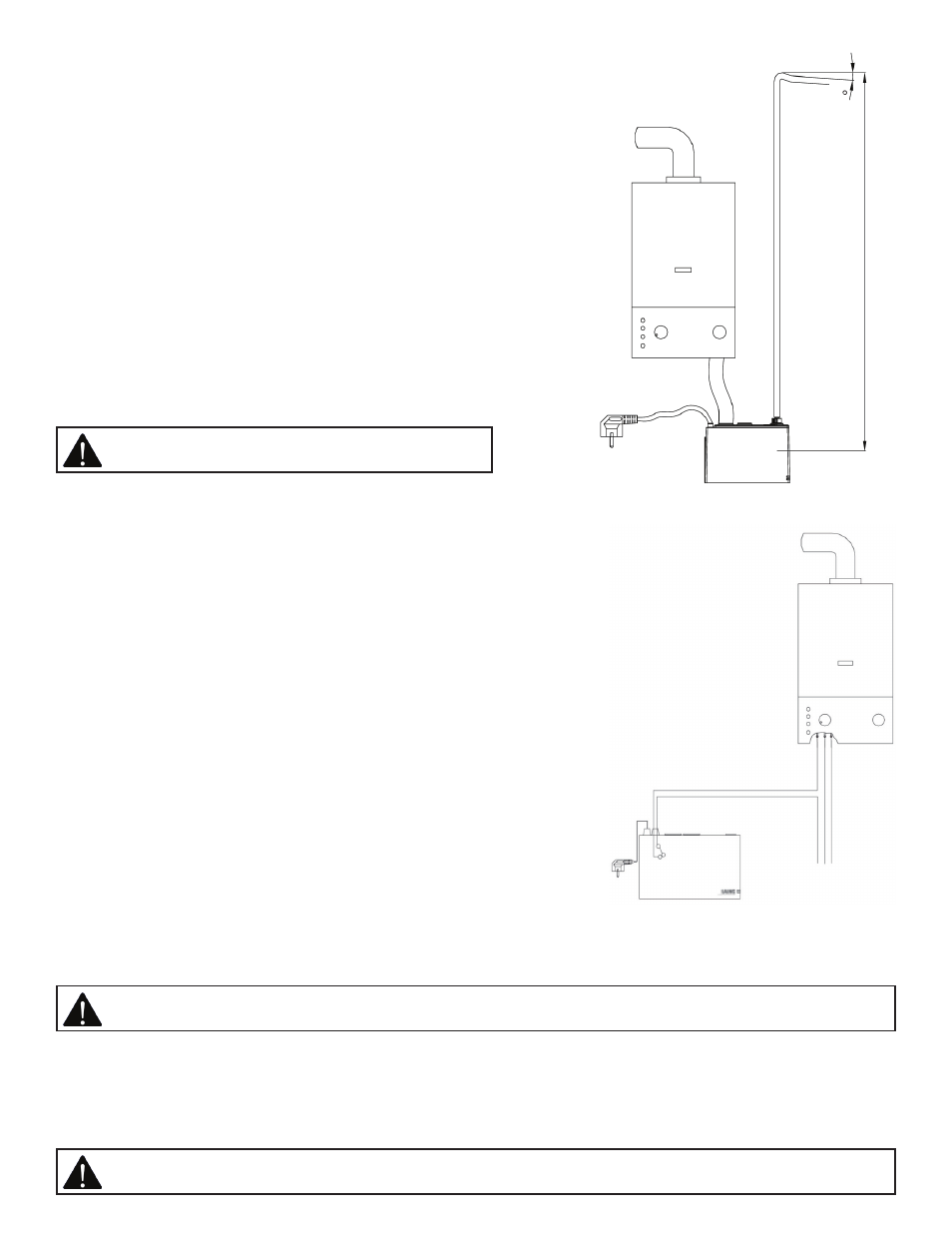

1. Condensate supply hose must be routed with a downward slope

to the LS Condensate Pump. (See Fig.5)

2. Ensure condensate supply hose is inserted deep enough into the

tank inlet so that it cannot slip out unintentionally. A second inlet

opening is available for additional hose connections.

3. For installation of the condensate drainage hose ensure hose is

inserted as far as possible onto the non-return valve. Tip: We

recommend that you also secure the hoses using hose clamps.

4. After securing hose on non-return valve, lock non- return valve by

rotating valve one quarter turn clockwise.

Electrical Connection

The LS has a 6.5 ft (2m) long mains cable with a shock-proof plug. If

the cable is not long enough, we recommend that you use an

extension lead or connect a distribution box. The mains cable is

permanently connected to the pump and cannot be removed and

replaced with a longer mains cable. The electrical connection used

must comply with the applicable standards. In particular, it must be

properly earthed and fused.

WARNING: All electrical work done may only be

performed by qualified electrical professionals.

max. 4m

4°

Fig.5

Alarm connection

The LS Condensate Pump is equipped with an alarm connection

(switching with a 15 sec delay). This allows the condensing or air

conditioning system to be switched off to prevent more condensate

being fed and the tank overflowing. If the alarm connection is to be

used, the 6.5 ft (2m) alarm connection cable must be connected as

shown in the illustration. If the cable is not long enough, we

recommend that you connect a distribution box. The alarm cable is

permanently connected to the pump and cannot be removed. If the

alarm connection is not used, the alarm cable can be cut off directly

at the pump. In order to prevent moisture penetrating into the

pump electronics, replace the original rubber cap with the hole with

the closed rubber cap provided.

Functional Testing

After installing the condensate pump, we recommend that you test

it to ensure that it functions correctly. To test the function, pour

water (approx. 0.4 l) into the tank – via the secondary inlet opening

if possible, until the activation level is reached and the pump starts.

If air in the pump causes the integrated dry-run protection to

actuate (pump deactivates, green and red operating lamp flash), add

a further 0.2 l of water and wait for one minute. The pump restarts

automatically after one minute. The LS condensate pump is now

functional.

Fig.6

L N PE

Routine Maintenance and Disassembly of LS Condensate Unit

The LS pump does not require special maintenance. However, we recommend that you remove encrustation and rinse

with clear water regularly in accordance with the occurrence of soiling. When you press in the clip, the LS can be

removed by pulling it upwards away from the mounting bracket (see exploded view illustration). Disassembly of the

condensate pump: Remove the pressure hose and non-return valve from the pump housing by turning them one

quarter turn counter-clockwise. Pull the condensate supply hose carefully out of the tank.

WARNING: The LS Condensate Pump must be disconnected from the mains power supply before maintenance

or disassembly!

WARNING: Condensate from condensing systems is aggressive. Avoid contact with residual condensate in the

tank, in the condensate supply hose or in the pressure hose!