Pam2319, Application information, Ordering information – Diodes PAM2319 User Manual

Page 10

PAM2319

Document number: DSxxxxx Rev. 1 - 1

10 of 12

www.diodes.com

November 2012

© Diodes Incorporated

PAM2319

A Product Line of

Diodes Incorporated

Application Information

(cont.)

Short Circuit Protection

Channel 1:

The swich peak current is limited cycle-by-cycle to a typical vaule in the event of an output voltage short circuit. The device operates with a

frequency of 1MHz and minimum duty clycle. Therefore the average input current is typical 350mA (V

IN

= 3.3V).

Channel 2:

When the converter output is shorted or the device is overloaded, each high-side MOSFET current-limit event (3A typ) turns off the high-side

MOSFET and turns on the low-side MOSFET. An internal counter is used to count the each current-limit event. The counter is reset after

consecutive high-side MOSFETs turn on without reaching current limit. If the current-limit condition persists, the counter fills up. The control logic

then stops both high-side and lowside MOSFETs and waits for a hiccup period, before attemping a new soft-start sequence. The counter bits is

decided by V

FB

voltage. If V

FB

0 2, the counter is 3-bit counter; if VFB > 0.2 the counter is 6-bit counter. The typical hicuup made duty cycle is

1.7%. The hiccup mode is disable during soft-start time.

PCB Layout Check List

When laying out the printed circuit board, the following checklist should be used to ensure proper operation of the PAM2319. Check the following

in your layout:

1. The input capacitor should be close to IC as close as possible.

2. Minimize the switching loop area to avoid excessive switching noise.

3. Two parts GND should be separately layout to avoid disturbing by each other.

4. Must put a small decoupling capacitor between Vin2 Pin and AGND2 Pin.

5. Vo2 output capacitor should be close to output connector to minimize PCB t race resistance affect on ripple voltage. Recommend use two

output capacitor, one close to inductor and IC, another close to output connector.

6. PGND1 Pin should not directly connect to the thermal pad (PGND), it should connect to input capacitor GND then to other GND.

7. AGND should connect to PGND at input capacitor GND.

8. For the good thermal dissipation, PAM2316 has a heat dissipate pad in the bottom side, it should be soldered to PCB surface. For the copper

area can't be large in the component side, so we can use multiple vias connect to other side of the PCB.

9. Avoid using vias in the high-current paths. If vias are unavoidable, use multiple vias in parallel to reduce resistance and inductance.

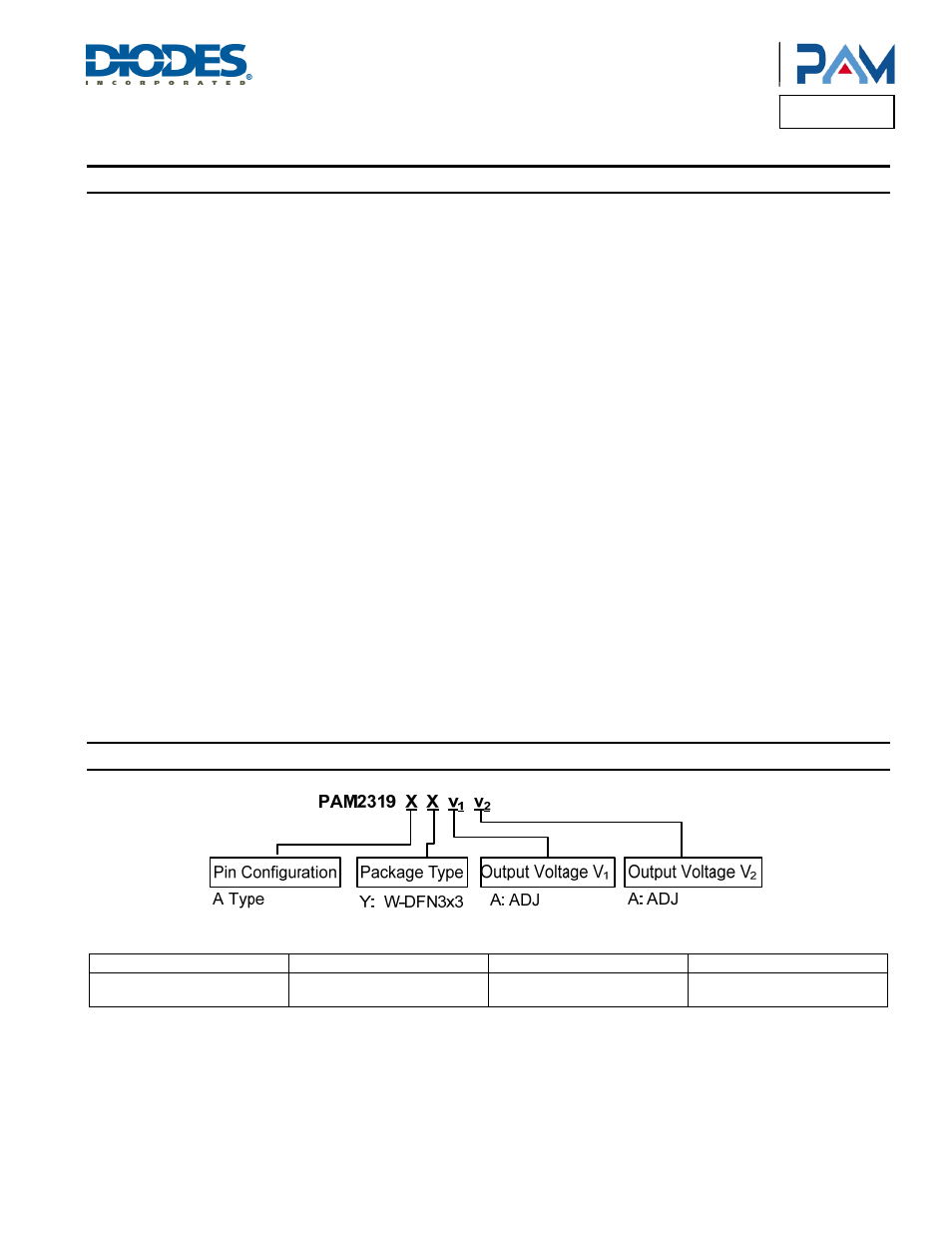

Ordering Information

Part Number

Part Marking

Package Type

Standard Package

PAM2319AYAA

BNAA

XXXYW

W-DFN3x3-12L

3000 Units/Tape & Reel