Gas connections, Procedure – Analytical Industries GPR-7500 AIS Trace PPM Hydrogen Sulfide Analyzer User Manual

Page 13

Advanced Instruments, Inc.

13

Gas Connections

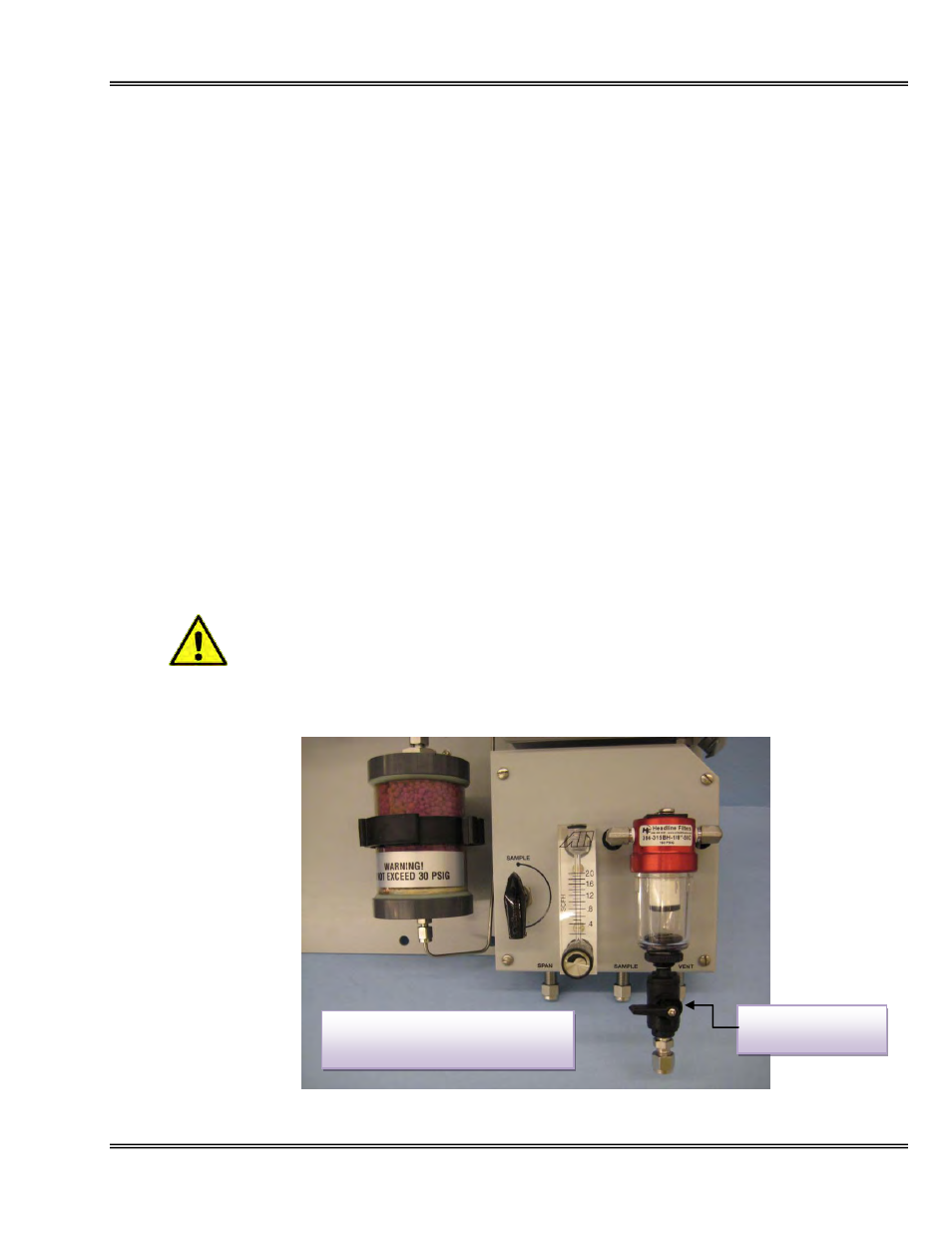

The GPR-7500AIS with its standard flow through configuration is designed for positive pressure samples

and requires connections for an incoming sample and an outgoing vent line. Zero and span inlet ports are

offered as part of the optional sample systems. The user is responsible for calibration gases and other

required components, see below.

Procedure

Caution: Do not change the factory setting until instructed to do in this manual.

1. If analyzer has a sample inlet and a sample vent line, connect the sample to SAMPLE and vent to the

VENT line.

2. Regulate the sample pressure as described in

“Pressure and Flow” section above.

3. Connect a

¼” vent line to the compression fitting to be used for venting the SAMPLE.

4. Connect a

¼” sample line to the compression fitting to be used to bring SAMPLE gas to the analyzer.

5. If equipped with optional SPAN and/or ZERO ports, connect the SPAN and the ZERO gas lines to the

respective SPAN and ZERO ports of the analyzer

6. Set the SAMPLE, SPAN and the ZERO gas pressure between 5-30 psig, keep the sample, span and

zero gas pressure within 5 PSIG of each other for better gas flow control..

7. Select sample gas and allow it to flow through the transmitters and set the flow rate to1- 2 SCFH.

8. Note: If equipped with the optional coalescing filter, regulate the inlet pressure less than 30 psig.

9. Flow rates of 1-5 SCFH cause no appreciable change in the sample reading. However, flow rates above

5 SCFH may generate a backpressure on the sensor and cause erroneous sample readings due to the

fact that the smaller diameter of the integral sample system tubing cannot vent the sample gas quickly

at higher flow rates. If the analyzer is not equipped with an integral flow control valve, a flow control

metering valve with a flow indicator upstream of the sensor must be installed to control the sample flow

rate. A flow rate of 1-2 SCFH or 0.5-1 L/min (liter per minute) is recommended for optimum

performance.

Caution: Do not place your finger over the vent (it pressurizes the sensor) to test the flow

indicator when gas is flowing to the sensor. Removing your finger (the restriction) generates a

sudden vacuum on the sensor and may lead to electrolyte leakage thus causing damage to the

sensor (will void sensor warranty).

Sample system shown with optional

coalescing filter and H2S scrubber

Coalescing filter

drain valve