Wavefront curvature – Ocean Optics Collimation tester User Manual

Page 3

Collimation Tester Instructions

CT-10000-000-05-201401

3

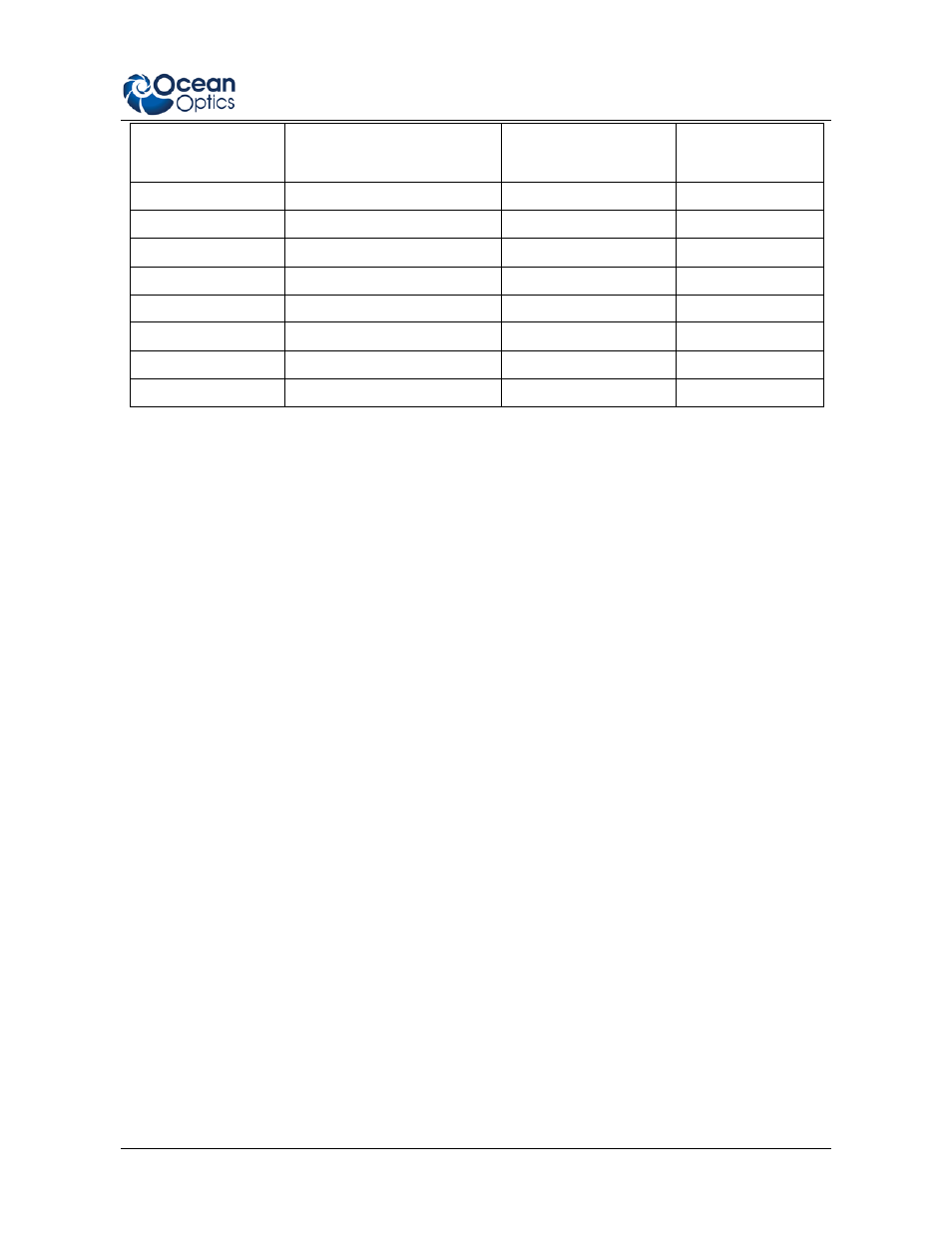

Collimation Tester

Aperture Size (in millimeters) Center thickness in

inches +/-.005"

Wedge angle in arc

seconds

CT-10

10

.040

22.5

CT-20

20

.118

11.8

CT-50

50

.375

4.7

CT-75

75

.500

3.2

CT-100

100

.500

2.4

CT-125

125

.625

1.9

CT-150

150

.767

1.6

CT-200

200

1.50

1.2

Using the Collimation Tester for Quantative

Measurements

Ocean Optics’ collimation testers are shearing interferometers. There are many shearing

interferometers but what they have in common is that the wavefront divided in amplitude, some shift

applied to one or both portions, which are then recombined to form an interference pattern. In the

collimation tester, the division arises from reflection at two faces of a slightly wedged plate. The shift

is due to the displacement from the plate thickness and the recombination occurs in the overlapped

images on the screen. Since the wavefront is being compared to itself rather than a reference flat

wavefront, interpretation of the fringes differs from the usual interferometer where the departure from

planarity is indicated by a fringe displacement. In the collimation tester, departure from planarity is

indicated by fringe slope. A treatment of the complete interpretation and analysis of shearing

interferograms is given by Rimmer(1).

Wavefront Curvature

The collimation tester was designed as a null instrument to indicate when the incident beam is parallel.

However, with large radius, spherical wavefronts, the fringes remain linear and can be analyzed to

determine the wavefront curvature (2)(3). With two, separated, spherical wavefronts, the interference

pattern can be treated in the same manner as the 2-pinhole experiment.

In the collimation tester, there are two separations:

• A vertical angle due to the wedge, and

• A horizontal angle proportional to the shear (beam displacement) and inversely proportional to

the wavefront radius.

The figure below illustrates the measurements required,

Where: d = Fringe spacing perpendicular to the fringes

A = Angle of the fringes with respect to the cursor

S = Shear