Dexter Laundry T-30X2 EXPRESS - Electric (On-Premise) User Manual

Page 6

-6-

should be made at the terminal blocks in the two control boxes on the rear of the unit using

conductors rated at 75 C (167 F) and a wire size adequate to handle the amperage and voltage

listed on the serial plate (see table on the next page for recommended minimum sizes). It is

absolutely necessary that the dryer be grounded to a known (earth) ground (No. 8 AWG copper

conductor recommended). Knockouts are provided for the connection of 1-inch conduit for the

power supply conductors and 3/8-inch conduit for the external grounding conductor.

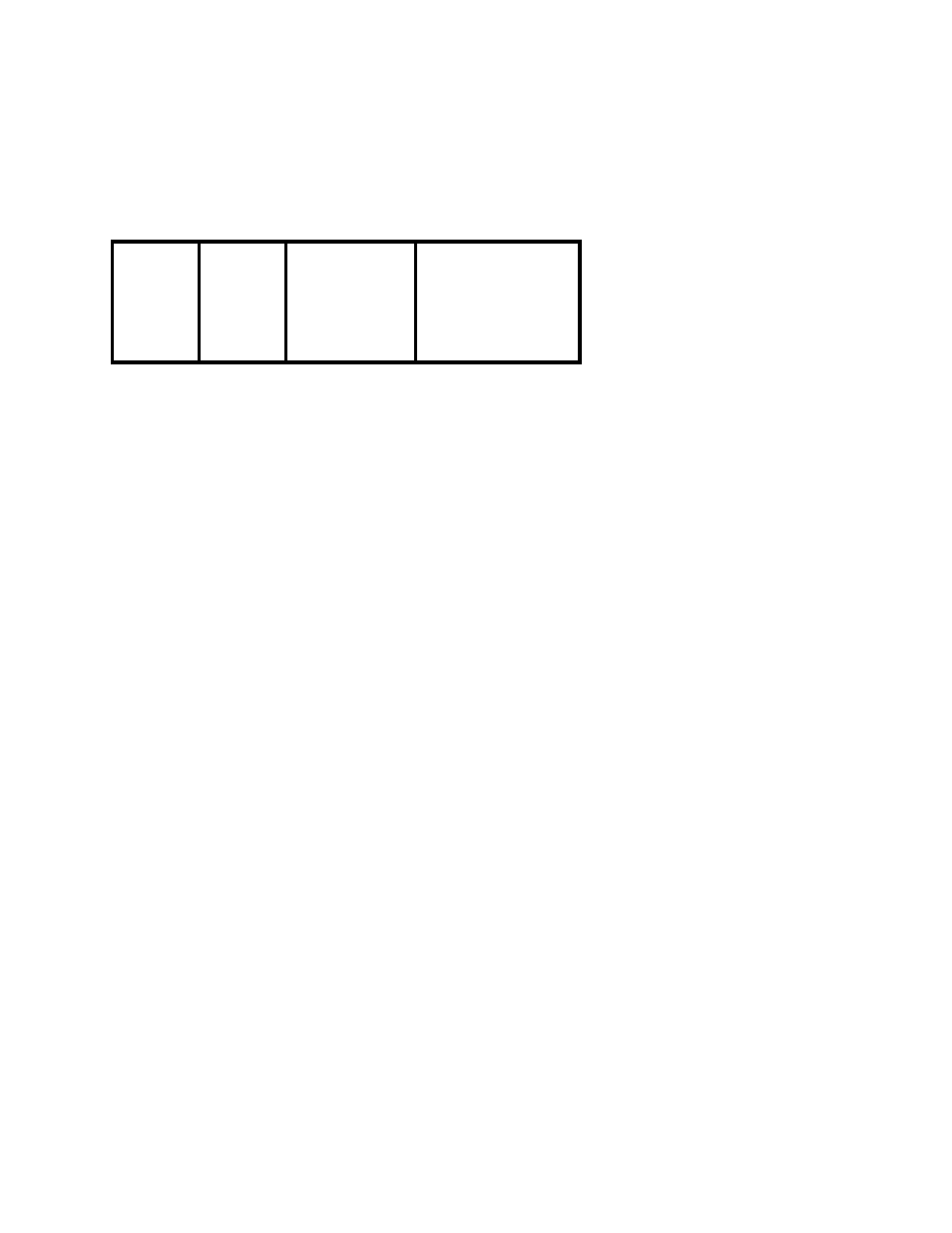

HEATING

ELEMENT

SIZE (kW)

SUPPLY

VOLTAGE

(

PHASE / V.

)

MINIMUM DUAL

ELEMENT TIME

DELAY FUSE

SIZE AT FUSED

DISCONNECT

(A.)

MINIMUM WIRE SIZE

FROM FUSED

DISCONNECT TO

DRYER TERMINAL

BLOCK (75

O

C

COPPER WIRE)

20

1 / 208

125

# 1/0

20

1 / 220

110

#1/0

20

1 / 240

110

# 1/0

24

3 / 208

90

# 2

24

3 / 240

80

# 3

24

3 / 400

50

# 6

30

3 / 400

60

# 4

36

3 / 400

70

# 3

For 240V power supplies, an earthed mid-point of a phase is required. The “high” leg of the 3-

phase electrical supply (delta) must be connected to terminal L3. A neutral is required for all

electrical supply variations; see the wiring diagram in the control box on the back of the dryer.

The installation must meet the electrical requirements of the country, state and locality of the

installation. The installer may be required to provide a disconnect switch which will interrupt

all lines. It may be a local or national requirement to provide an electrical interruption switch

visible and accessible from the room in which the dryer is installed. The wiring diagram is

located in the control box on the back of the dryer.

MISE À LA TERRE

Cet appareil doit être relié à une canalisation électrifique métallique fixe ou la dérivation doit

comporter un conducteur de terre connecté à la bome ou au fil de terre de l’appareil.

6. EXHAUST INSTALLATION. (Refer to Figure 3) Exhausting of the dryer(s) should be

planned and constructed so that no air restrictions occur. Any restriction due to pipe size or type

of installation can cause slow drying time, excessive heat, and lint in the room.

From an operational standpoint, incorrect or inadequate exhausting can cause a cycling of the

high limit thermostat, which shuts off the heating elements and results in inefficient drying.

The oval exhaust duct connection near the top of the dryer will accept a compressed 8” round

duct. Individual exhausting of the dryers is recommended. A pipe of the proper diameter should

be attached to the dryer adapter collar and extended out through an outside wall to exhaust all

heat, moisture, and lint outside. This pipe must be very smooth on the inside, as rough surfaces