Ironwood Electronics SS-BGA User Manual User Manual

Page 9

SSI.doc, Rev. A, IP

Rev. B/C/D, RP

Rev. E, VP

8

Tel: (800) 404-0204 • (952) 229-8200

Fax: (952) 229-8201

11351 Rupp Dr. Suite 400, Burnsville, MN 55337

www.ironwoodelectronics.com

16g (0.56oz) at 0.150” (3.81mm) recommended operating position

Spring pin cycle life

500,000 cycles

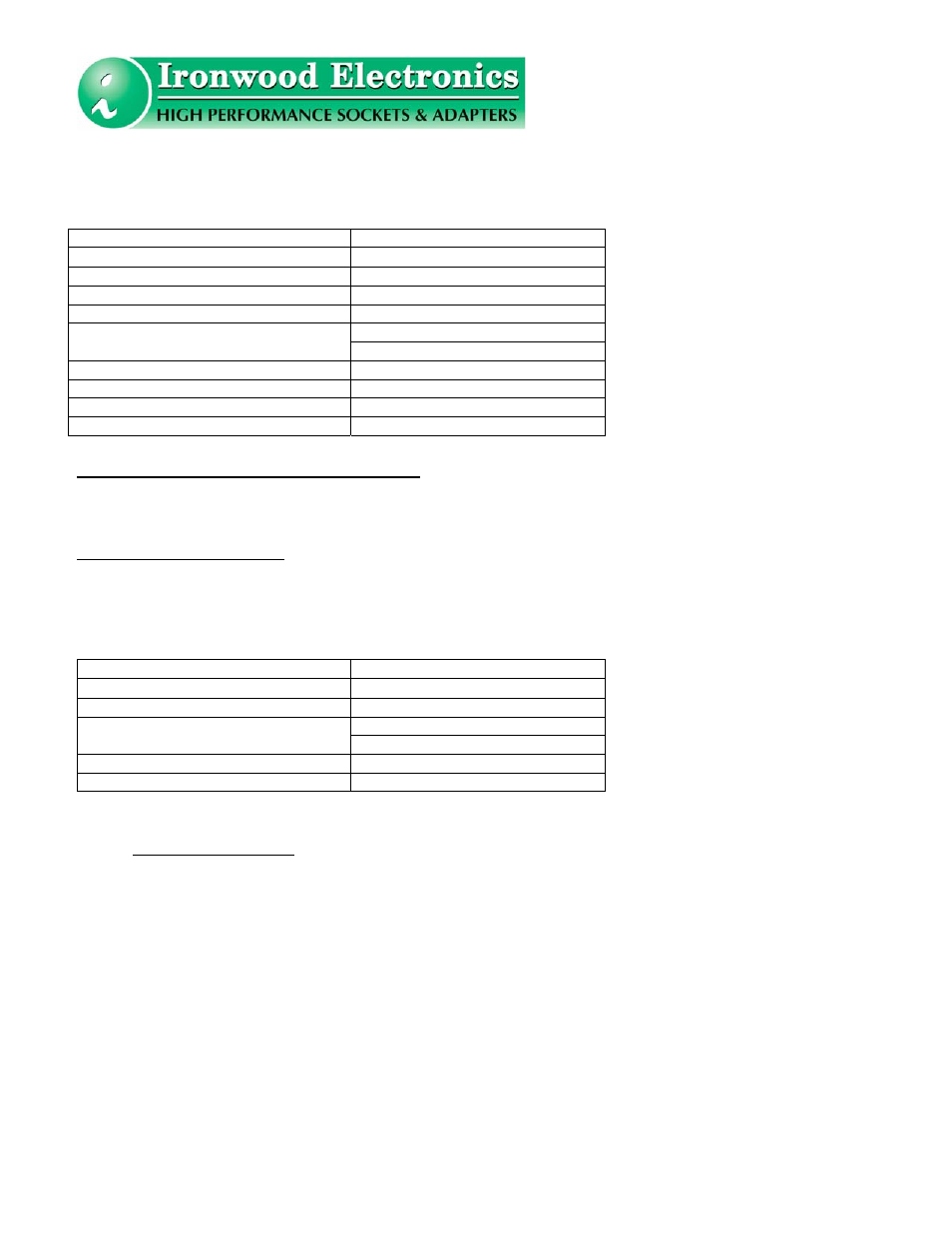

Electrical Specifications

P-P115A / P-P139A

Contact resistance:

82.28m

Ω

Self Inductance:

1.3nH

Mutual Inductance:

0.15nH

Cross talk:

<-15dB to 6.5GHz

<0.25dB to 4.5 GHz

Insertion loss:

<3dB to 10 GHz

Rise time

<26 ps

Pin to ground Capacitance:

0.53pF

Pin to pin Capacitance:

0.045pF

Current carrying capacity:

2.5A

0.4mm Center - Spring Probe Specification

Operating Temperature

Continuous usage: -40°C to +120°C

Mechanical Specifications

Individual spring pin force

20g (0.7oz) at operating position

Spring pin cycle life

500,000 cycles

Electrical Specifications

P-P136A / P-P134A

Contact resistance:

62m

Ω

Self Inductance:

1.1nH

<1dB to 11.5 GHz

Insertion loss:

<3dB to 19.3 GHz

Pin to ground Capacitance:

0.58pF

Current carrying capacity:

1.5A

Socket Maintenance

Setting up a Preventative Maintenance Program is important in maintaining both Socket and Test Probe

life expectancy as well as good electrical continuity which will help minimize false rejects and low test

yields. Generally, light cleaning is recommended for a preventative maintenance program of the test

socket assembly. The most effective way to determine a schedule is by tracking test yields. The

maintenance schedule should be based on when yields begin to fall below the performance of a new test

socket. Some customers perform light cleanings on a per day basis or at 20,000 or 50,000 cycle intervals.

The schedule depends on the amount of debris or contamination that the socket and test probes are subject

to.

The following items should be included in a typical maintenance program.