R&M Materials Handling VARIABLE SPEED CONTROLS ControlMaster NXT Service Manual User Manual

Page 25

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

25/53

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

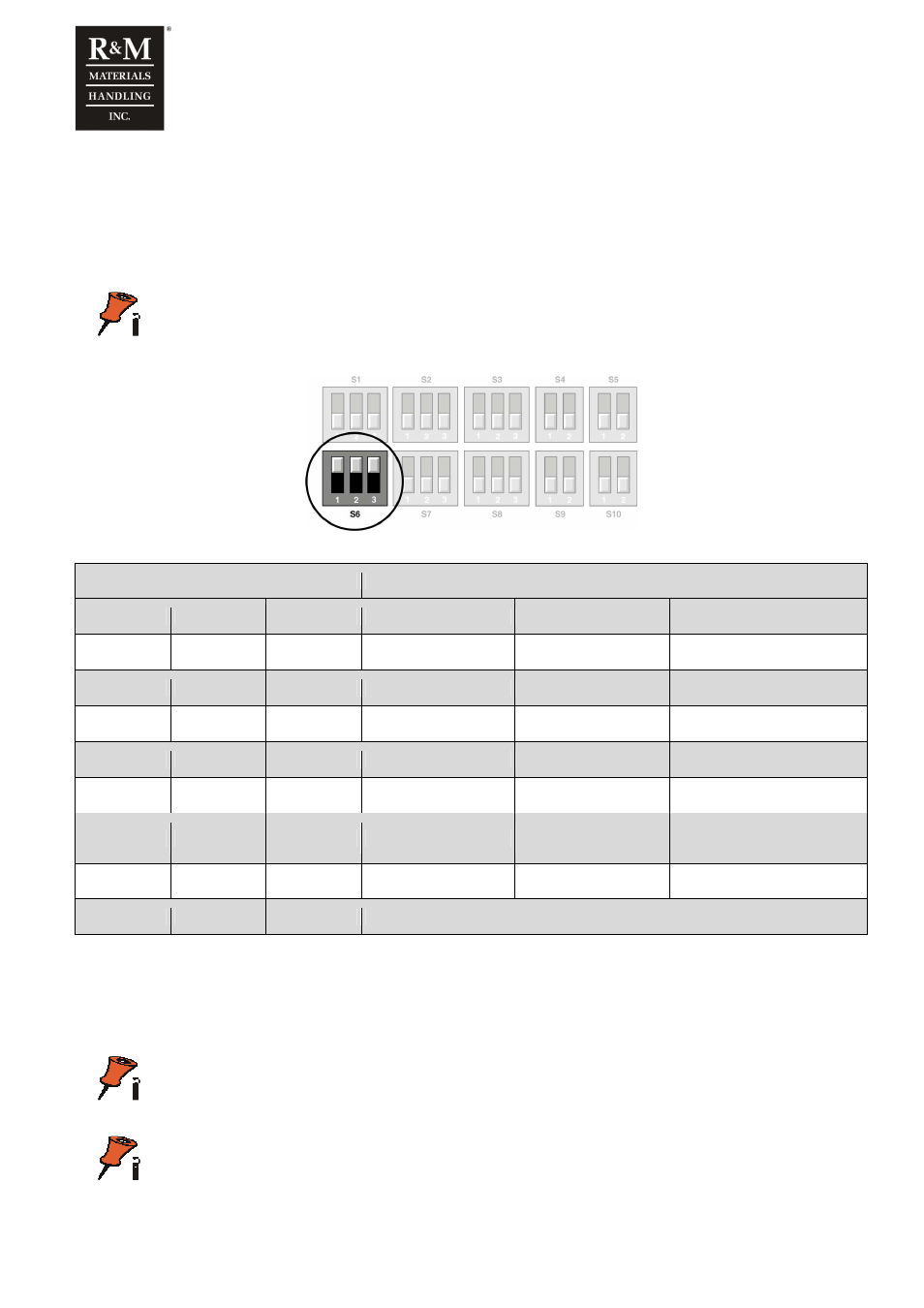

5.2.4 S6 U/f curve settings in traveling movement application

The effect of stator resistance at low frequencies is compensated for by increasing the U/f-ratio. The U/f curve

settings for the different motors are shown in the following table.

Note:

• Zero Freq Volt[%] = output voltage at 0 Hz given as a percentage of the voltage at the motor’s nominal frequency.

• U/f Mid Volt[%] = output voltage at U/f-curve’s intermediate point, fixed to 10 % of motor nominal frequency, given as a

percentage of the voltage at the motor’s nominal frequency.

Switch S6

U/f curve settings

-1

-2

-3

Zero Freq Volt

[%]

U/f Mid Volt [%]

Motor Type

0

1

0

6

12

MF06LA100

1

0

1

6.5

12

MF06LA100(*)

0

0

0

8

12

MF06LA200

1

1

0

8.5

12

MF06LA200(*)

0

1

1

9

16

MF06MA100

0

0

1

10

14

MF06MA200, MF06MK200

(100/120Hz)

1

0

0

21

24

MF06MK200 (35Hz)

1

1

1

Used in a chain hoist lifting application. See section “Parameters for chain hoist lifting”.

(*) Denotes a boost function that provides extra torque for specific motors driven at low frequencies. The function

can be used when motors cannot otherwise move at low speeds. When the curve number 3 or 6 is selected, the

current limit shall be increased to 150% which is set at factory as standard.

Note: Authorized service personnel are allowed to change the curve number 1 to the curve number 3, and the curve number 4

to the curve number 6.

Note: Before activating the torque boost function, drive a few times on the runway at high speed to flatten the runway. If this

does not help, the boost function can be activated.