Power supply requirements, Communicating with the vfg9000-pbdp option card, Software/unit operation – B&B Electronics VFG9000-PBDP - Quick Start Guide User Manual

Page 3

POWER SUPPLY REQUIREMENTS

NEW AND EXISTING INSTALLATIONS

The VFG9000-PBDP option card draws all of its power from the main board

of the Fieldbus Gateway. The specifications of the Fieldbus Gateway account

for the power needs of an option card.

COMMUNICATING WITH THE VFG9000-PBDP

OPTION CARD

CONFIGURING THE VFG9000-PBDP OPTION CARD

The VFG9000-PBDP is configured using Fieldbus Gateway Manager software.

Updates to the software for new features and drivers are posted on the website

as they become available. By configuring the VFG9000-PBDP using the latest

version of the software, you are assured that your unit has the most up-to-date

feature set. Additional information can be found in your hardware bulletin and

also in the Fieldbus Gateway Manager user manual.

To enable the option card, click on the left hand pane of the Communications

window in Fieldbus Gateway Manager and highlight the icon that represents the

Fieldbus Gateway. In the right pane, click the Option Card Selection’s Edit

button to show the selection dialog, and choose the PROFIBUS option card

from the list. The PROFIBUS option card will then appear in the left hand pane,

installed in the tree of available ports.

CONFIGURING THE DRIVER

To select a driver, click on the left hand pane of the Communications window

and highlight the PROFIBUS Interface icon. In the right hand pane, click the

Driver Selection Edit button to show the Driver Selection dialog and select the

PROFIBUS DP driver from the list.

The Station Address of the PROFIBUS node is the only property that needs

to be configured. This should be a unique address on the PROFIBUS Network

in the range 1..125.

CONFIGURING THE DATA TAGS

A PROFIBUS master exchanges data with slaves as separate input and output

blocks. Data transfer direction is described with respect to the PROFIBUS

Network such that input data is transferred to the network, or written by the

Fieldbus Gateway and output data is transferred from the network or read by the

Fieldbus Gateway. This is important when it comes to configuring the data

access for each tag mapped to a PROFIBUS data block.

MAPPING TAGS TO PROFIBUS

PROFIBUS data blocks have no concept or knowledge of data type or

structure – they are described by a size in bytes. Fieldbus Gateway Manager’s

tag-based approach to data allows for data of mixed type, bytes, 16-bit words,

32-bit words and 32-bit floating point numbers to be mapped into a single data

block. To map a data tag to a PROFIBUS data block, click in the left hand pane

of the Data Tags window, highlight the required Data Tag icon. In the right hand

pane click the Data Mapping button and select the PROFIBUS device to show

the Select Address for PROFIBUS DP dialog.

The Block Type defines whether the tag will be read from (Output Block) or

written to (Input Block) the PROFIBUS network

The Data Offset is the byte address of the Data Tag within the Data Block

The Data Type is the actual size in bytes of the data that will be mapped into

the Data Block.

SOFTWARE/UNIT OPERATION

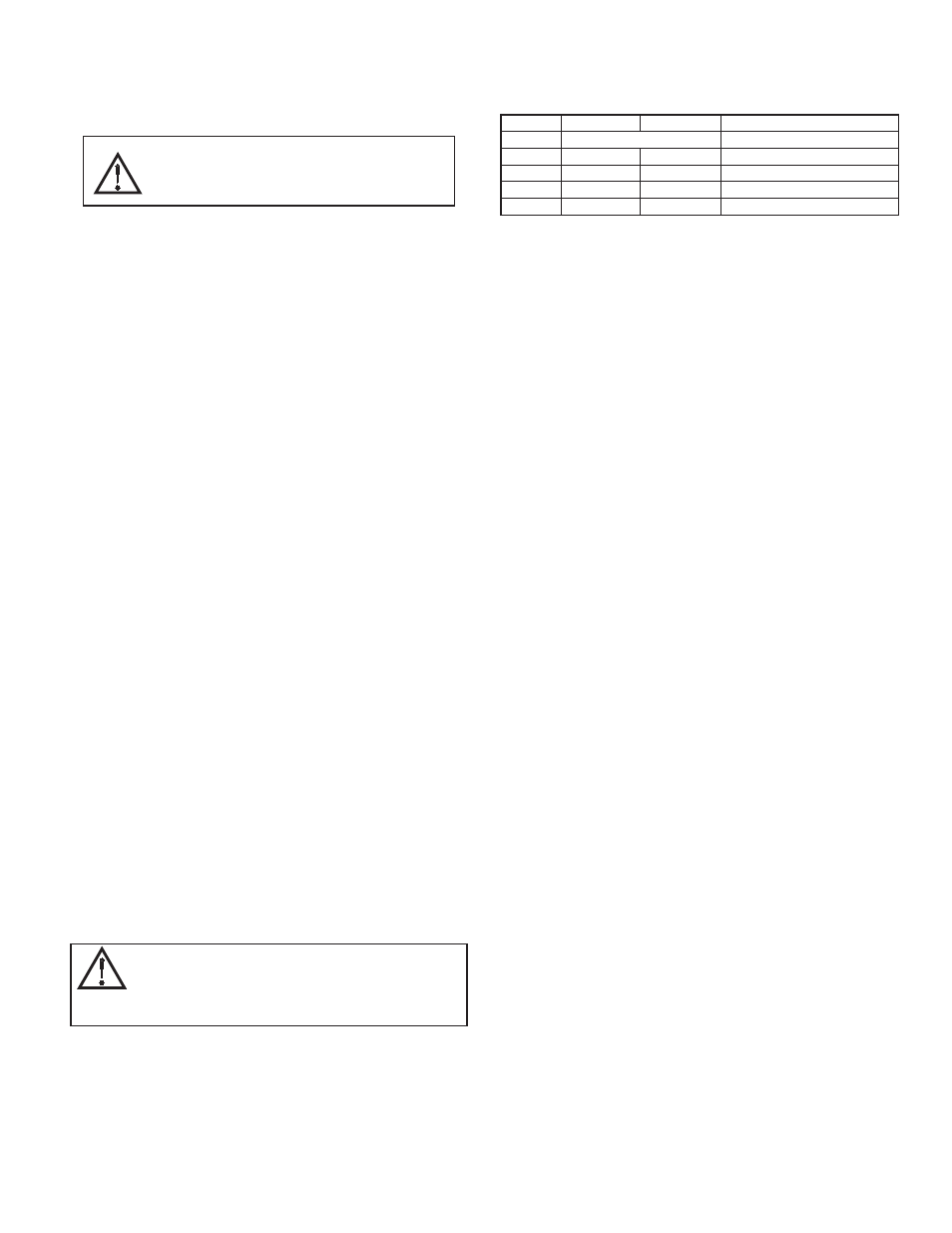

LEDS

The card has 3 LEDs visible on the front of the option card that provide status

information, described in Table 1.

TROUBLESHOOTING YOUR VFG9000-PBDP OPTION CARD

If for any reason you have trouble operating, connecting, or simply have

questions concerning your new VFG9000-PBDP option card, contact B&B

Electronics’ technical support. For contact information, refer to the back page

of this bulletin for phone and fax numbers.

Web Site: http://www.bb-elec.com

DATA (Red)

WD (Green)

DP (Red)

DESCRIPTION

OFF

Baud Search

OFF

OFF

ON

Baud Control

OFF

SLOW FLASH FAST FLASH

OFF

FAST FLASH SLOW FLASH

ON

OFF

OFF

Data Exchange

SLOW ALTERNATING FLASH

Waiting for Parameter Telegram

Waiting for Configuration Telegram

CONFIGURING DATA ACCESS IN

FIELDBUS GATEWAY MANAGER

As described, Data Tags are mapped to either an Input Block

and are Write only, or an Output Block and are Read Only. The

Access must be selected to reflect this.

3

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT

WHILE CIRCUIT IS ALIVE UNLESS AREA IS KNOW TO BE

NON-HAZARDOUS.