Table 3. component selection guide – Rainbow Electronics MAX1706 User Manual

Page 15

MAX1705/MAX1706

1- to 3-Cell, High-Current, Low-Noise,

Step-Up DC-DC Converters with Linear Regulator

______________________________________________________________________________________

15

To set the low-dropout linear-regulator output, use a

resistor voltage-divider connected to FBLDO from LDO

to GND. Set the output to a value at least 300mV less

than the step-up converter output using the following

formula:

where V

FBLDO

, the linear-regulator feedback trip point,

is 1.250V. Since the input bias current into FBLDO is

less than 50nA, R4 can be a large value (such as

270k

Ω

or less). Connect the resistor voltage-divider as

close to the IC as possible, within 0.2in. (5mm) of the

FBLDO pin.

Inductor Selection

The MAX1705/MAX1706’s high switching frequency

allows the use of a small surface-mount inductor. Use a

10µH inductor for the MAX1705 and a 22µH inductor

for the MAX1706. Make sure the saturation-current rat-

ing exceeds the N-channel switch current limit of 1.55A

for the MAX1705 and 950mA for the MAX1706. For high

efficiency, chose an inductor with a high-frequency

core material, such as ferrite, to reduce core losses. To

minimize radiated noise, use a torroid, pot core, or

shielded-bobbin inductor. See Table 3 for suggested

parts and Table 4 for a list of inductor suppliers.

Connect the inductor from the battery to the LX pin as

close to the IC as possible.

Attaching the Output Diode

Use a Schottky diode, such as a 1N5817, MBR0520L,

or equivalent. The Schottky diode carries current during

start-up, and in PFM mode after the synchronous rectifi-

er turns off. Thus, the current rating only needs to be

500mA. Attach the diode between the LX and POUT

pins, as close to the IC as possible.

In high-temperature applications, some Schottky

diodes may be unsuitable due to high reverse-leakage

currents. Try substituting a Schottky diode with a higher

reverse voltage rating, or use an ultra-fast silicon rectifi-

er with reverse recover times less than 60ns (such as a

MUR150 or EC11FS1). Do not use ordinary rectifier

diodes, since slow switching speeds and long re-

verse recovery times compromise efficiency and load

regulation.

Choose Input and Output

Filter Capacitors

Choose input and output filter capacitors that service

the input and output peak currents with acceptable

voltage ripple. Choose input capacitors with working

voltage ratings over the maximum input voltage, and

output capacitors with working voltage ratings higher

than the output.

A 100µF, 100m

Ω

, low-ESR tantalum capacitor is recom-

mended at the MAX1706’s step-up output. For the

MAX1705, use two in parallel or a 220µF low-ESR tanta-

lum capacitor. The input filter capacitor (C7) also

reduces peak currents drawn from the input source

and reduces input switching noise. The input voltage

source impedance determines the size required for the

input capacitor. When operating directly from one or

two NiCd cells placed close to the MAX1705/MAX1706,

use a 22µF, low-ESR input filter capacitor. When

operating from a power source placed farther away, or

R

R

V

V

LDO

FBLDO

3

4

=

- 1

OUT

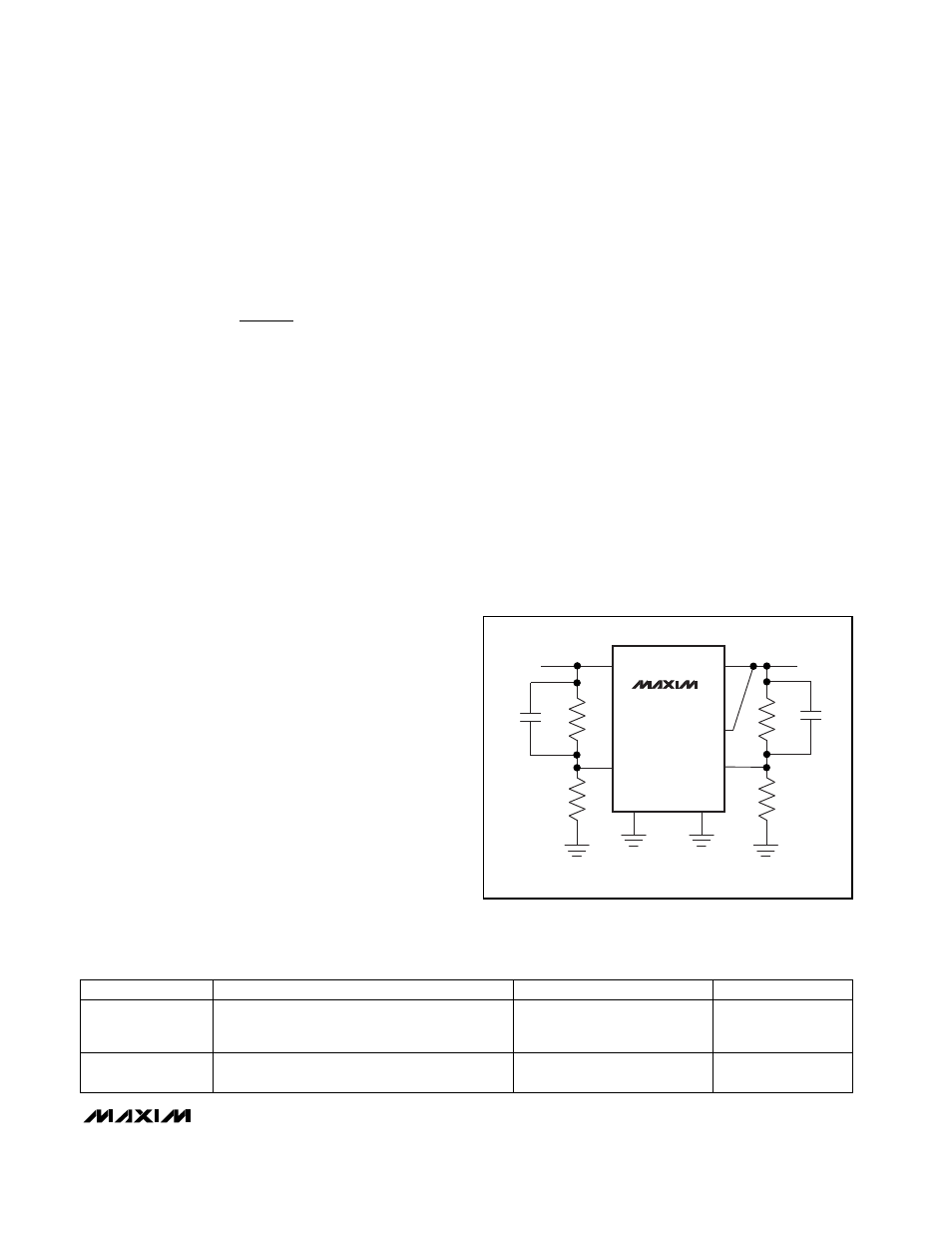

POUT

FB

FBLDO

LDO

GND

PGND

MAX1705

MAX1706

STEP-UP

OUTPUT

LINEAR-

REGULATOR

OUTPUT

R1

R2

R3

R4

C1*

C2*

* OPTIONAL COMPENSATION CAPACITORS

Figure 8. Feedback Connections for the MAX1705/MAX1706

PRODUCTION

INDUCTORS

CAPACITORS

DIODES

Surface Mount

Sumida CDR63B, CD73, CDR73B, CD74B series

Coilcraft DO1608, DO3308, DT3316 series

Matsuo 267 series

Sprague 595D series

AVX TPS series

Motorola MBR0520L

Through Hole

Sumida RCH654 series

Sanyo OS-CON series

Nichicon PL series

Motorola 1N5817

Table 3. Component Selection Guide