Hot swap – Rainbow Electronics MAX3033E User Manual

Page 9

Machine Model

The Machine Model for ESD tests all pins using a

200pF storage capacitor and zero discharge resis-

tance. Its objective is to emulate the stress caused by

contact that occurs with handling and assembly during

manufacturing. Of course, all pins require this protec-

tion during manufacturing, not just inputs and outputs.

Therefore, after PC board assembly, the Machine

Model is less relevant to I/O ports.

Hot Swap

When circuit boards are plugged into a “hot” back-

plane, there can be disturbances to the differential sig-

nal levels that could be detected by receivers

connected to the transmission line. This erroneous data

could cause data errors to an RS-422 system. To avoid

this, the MAX3030E–MAX3033E have hot-swap capa-

ble inputs.

When a circuit board is plugged into a “hot” backplane,

there is an interval during which the processor is going

through its power-up sequence. During this time, the

processor’s output drivers are high impedance and are

unable to drive the enable inputs of the MAX3030E–

MAX3033E (EN, EN, EN_) to defined logic levels.

Leakage currents from these high-impedance drivers,

of as much as 10µA, could cause the enable inputs of

the MAX3030E–MAX3033E to drift high or low.

Additionally, parasitic capacitance of the circuit board

could cause capacitive coupling of the enable inputs to

either GND or V

CC

. These factors could cause the

enable inputs of the MAX3030E–MAX3033E to drift to

levels that may enable the transmitter outputs. To avoid

this problem, the hot-swap input provides a method of

holding the enable inputs of the MAX3030E–MAX3033E

in the disabled state as V

CC

ramps up. This hot-swap

input is able to overcome the leakage currents and par-

asitic capacitances that can pull the enable inputs to

the enabled state.

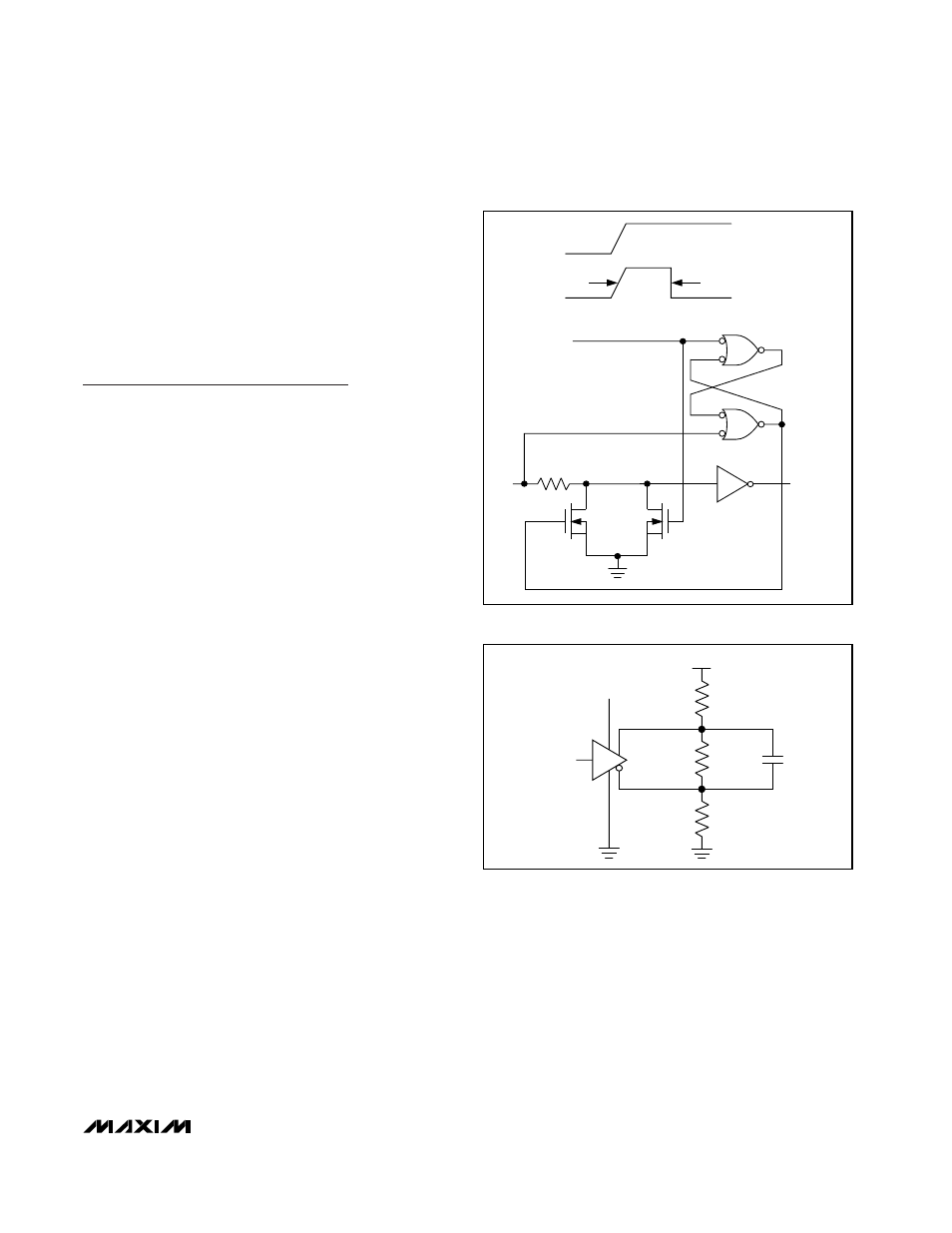

Hot-Swap Input Circuitry

In the MAX3030E–MAX3033E, the enable inputs feature

hot-swap capability. At the input there are two NMOS

devices, M1 and M2 (Figure 10). When V

CC

is ramping

up from zero, an internal 6µs timer turns on M2 and sets

the SR latch, which also turns on M1. Transistors M2, a

2mA current sink, and M1, a 100µA current sink, pull EN

to GND through a 5.6k

Ω resistor. M2 is designed to pull

the EN input to the disabled state against an external

parasitic capacitance of up to 100pF that is trying to

enable the EN input. After 6µs, the timer turns M2 off and

M1 remains on, holding the EN input low against three-

state output leakages that might enable EN. M1 remains

on until an external source overcomes the required input

current. At this time the SR latch resets and M1 turns off.

When M1 turns off, EN reverts to a standard, high-

impedance CMOS input. Whenever V

CC

drops below

1V, the hot-swap input is reset. The EN1&2 and EN3&4

input structures are identical to the EN input. For the EN

input, there is a complementary circuit employing two

PMOS devices pulling the EN input to V

CC

.

Hot-Swap Line Transient

The circuit of Figure 11 shows a typical offset termina-

tion used to guarantee a greater than 200mV offset

when a line is not driven. The 50pF capacitor repre-

MAX3030E–MAX3033E

±15kV ESD-Protected, 3.3V Quad

RS-422 Transmitters

_______________________________________________________________________________________

9

EN

DE

(HOT SWAP)

5.6k

Ω

TIMER

TIMER

V

CC

6

µs

M2

M1

2mA

100

µA

Figure 10. Simplified Structure of the Driver Enable Pin (EN)

V

CC

DI_

(V

CC

OR GND)

3.3V

DO_+

DO_-

50pF

0.1k

Ω

1k

Ω

1k

Ω

Figure 11. Differential Power-Up Glitch (Hot Swap)