Chip information – Rainbow Electronics MAX1618 User Manual

Page 14

MAX1618

Remote Temperature Sensor

with SMBus Serial Interface

14

______________________________________________________________________________________

6) When introducing a thermocouple, make sure that

both the DXP and the DXN paths have matching

thermocouples. In general, PC board-induced ther-

mocouples are not a serious problem. A copper-

solder thermocouple exhibits 3µV/°C, and it takes

approximately 200µV of voltage error at DXP-DXN to

cause a +1°C measurement error, so most parasitic

thermocouple errors are swamped out.

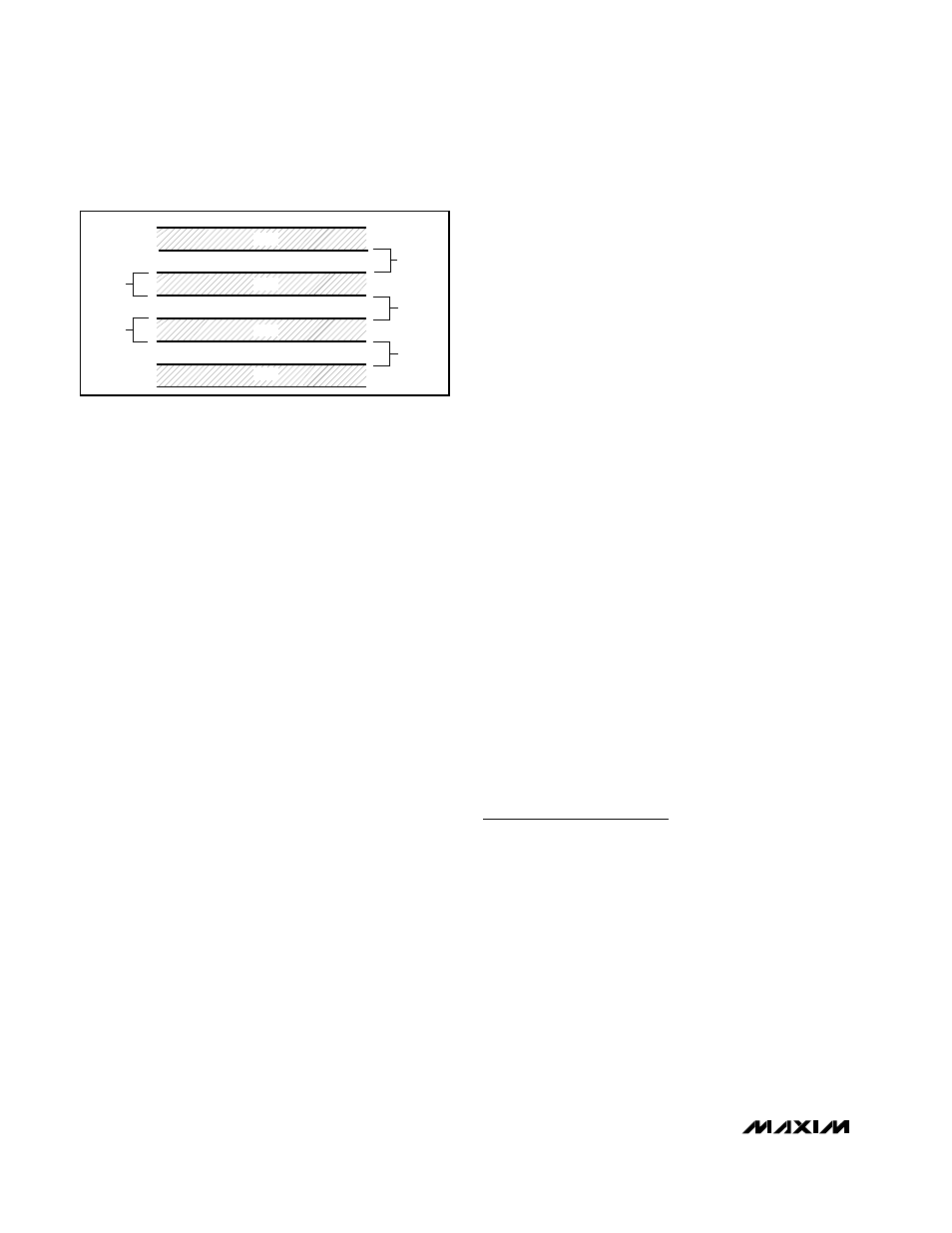

7) Use wide traces. Narrow traces are more inductive

and tend to pick up radiated noise. The 10mil

widths and spacings recommended in Figure 5 are

not absolutely necessary (as they offer only a minor

improvement in leakage and noise), but try to use

them where practical.

8) Note that copper cannot be used as an EMI shield.

Use only ferrous materials such as steel. Placing a

copper ground plane between the DXP-DXN traces

and traces carrying high-frequency noise signals

does not help reduce EMI.

Twisted Pair and Shielded Cables

For remote-sensor distances longer than 8 inches, or in

particularly noisy environments, a twisted pair is recom-

mended. Its practical length is 6 feet to 12 feet (typ)

before noise becomes a problem, as tested in a noisy

electronics laboratory. For longer distances, the best

solution is a shielded twisted pair like that used for audio

microphones. For example, Belden #8451 works well for

distances up to 100 feet in a noisy environment. Connect

the twisted pair to DXP and DXN and the shield to GND,

and leave the shield’s remote end unterminated.

Excess capacitance at DX_ limits practical remote-sen-

sor distances (see Typical Operating Characteristics).

For very long cable runs, the cable's parasitic capaci-

tance often provides noise filtering, so the recommended

2200pF capacitor can often be removed or reduced in

value.

Cable resistance also affects remote-sensor accuracy. A

1

Ω series resistance introduces about +1/2°C error.

Programming Example:

Clock-Throttling Control for CPUs

Listing 1 gives an untested example of pseudocode for

proportional temperature control of Intel mobile CPUs

through a power-management microcontroller. This pro-

gram consists of two main parts: an initialization routine

and an interrupt handler. The initialization routine checks

for SMBus communications problems and sets up the

MAX1618 configuration. The interrupt handler responds

to ALERT signals by reading the current temperature and

setting a CPU clock duty factor proportional to that tem-

perature. The relationship between clock duty and tem-

perature is fixed in a look-up table contained in the

microcontroller code.

Note: Thermal management decisions should be made

based on the latest external temperature obtained from

the MAX1618 rather than the value of the Status Byte.

The MAX1618 responds very quickly to changes in its

environment due to its sensitivity and its small thermal

mass. High and low alarm conditions can exist at the

same time in the Status Byte, because the MAX1618 is

correctly reporting environmental changes around it.

MINIMUM

10 MILS

10 MILS

10 MILS

10 MILS

GND

DXN

DXP

GND

Figure 6. Recommended DXP/DXN PC Traces

Chip Information

TRANSISTOR COUNT: 9911