Design procedure – Rainbow Electronics MAX799 User Manual

Page 19

MAX796/MAX797/MAX799

Step-Down Controllers with

Synchronous Rectifier for CPU Power

______________________________________________________________________________________

19

_________________Design Procedure

The five pre-designed standard application circuits

(Figure 1 and Table 1) contain ready-to-use solutions

for common applications. Use the following design pro-

cedure to optimize the basic schematic for different

voltage or current requirements. Before beginning a

design, firmly establish the following:

V

IN(MAX)

, the maximum input (battery) voltage.

This

value should include the worst-case conditions, such

as no-load operation when a battery charger or AC

adapter is connected but no battery is installed.

V

IN(MAX)

must not exceed 30V. This 30V upper limit is

determined by the breakdown voltage of the BST float-

ing gate driver to GND (36V absolute maximum).

V

IN(MIN)

, the minimum input (battery) voltage.

This

should be taken at full-load under the lowest battery

conditions. If V

IN(MIN)

is less than 4.5V, a special circuit

must be used to externally hold up VL above 4.8V. If

the minimum input-output difference is less than 1.5V,

the filter capacitance required to maintain good AC

load regulation increases.

Inductor Value

The exact inductor value isn’t critical and can be

adjusted freely in order to make tradeoffs among size,

cost, and efficiency. Although lower inductor values will

minimize size and cost, they will also reduce efficiency

due to higher peak currents. To permit use of the physi-

cally smallest inductor, lower the inductance until the

circuit is operating at the border between continuous

and discontinuous modes. Reducing the inductor value

even further, below this crossover point, results in dis-

continuous-conduction operation even at full load. This

helps reduce output filter capacitance requirements but

causes the core energy storage requirements to

increase again. On the other hand, higher inductor val-

ues will increase efficiency, but at some point resistive

losses due to extra turns of wire will exceed the benefit

gained from lower AC current levels. Also, high induc-

tor values can affect load-transient response; see the

V

SAG

equation in the

Low-Voltage Operation

section.

The following equations are given for continuous-con-

duction operation since the MAX796 is mainly intended

for high-efficiency battery-powered applications. See

Appendix A in Maxim’s

Battery Management and DC-

DC Converter Circuit Collection

for crossover point and

discontinuous-mode equations. Discontinuous conduc-

tion doesn’t affect normal idle-mode operation.

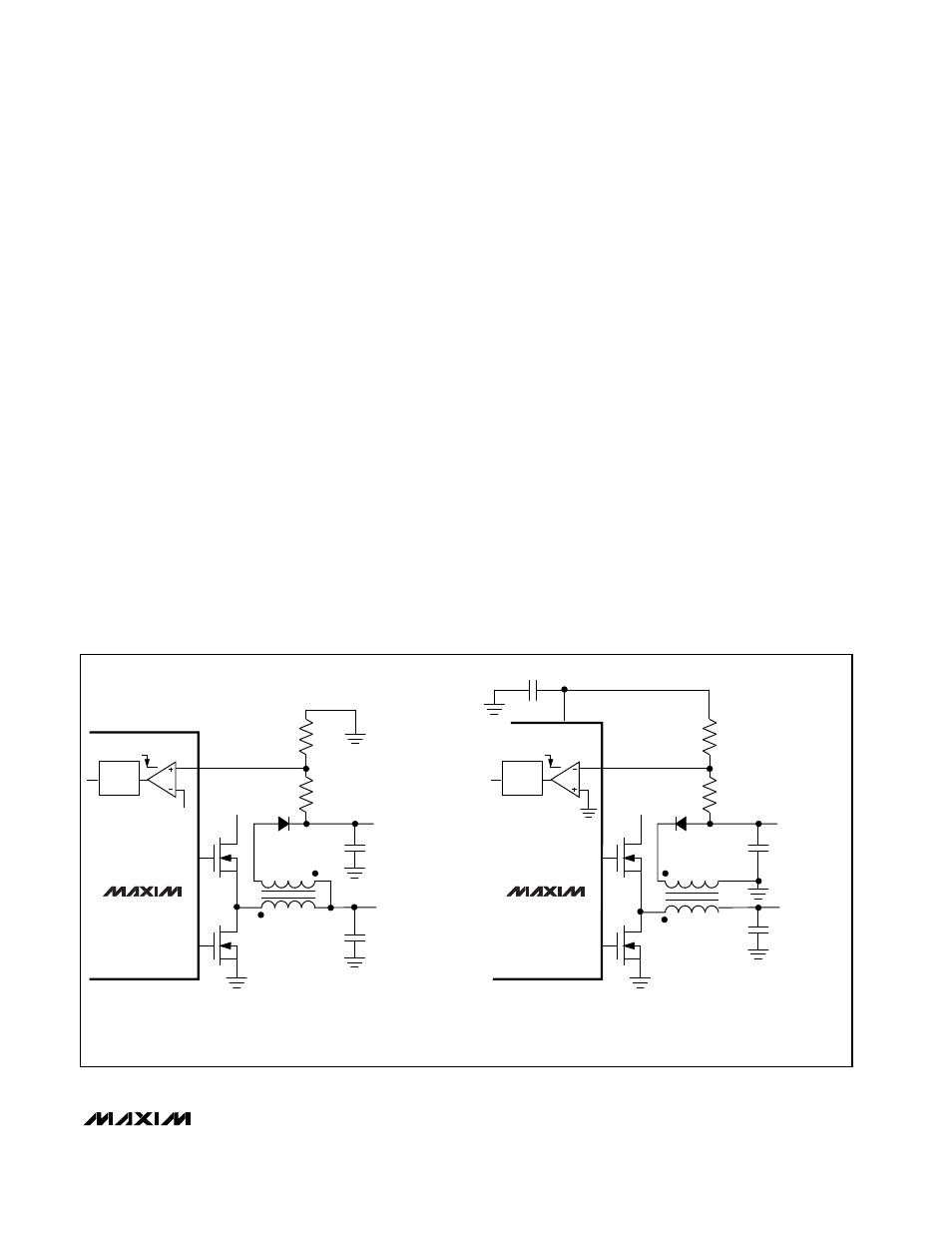

MAX799

NEGATIVE

SECONDARY

OUTPUT

MAIN

OUTPUT

DH

V+

SECFB

R3

R2

1-SHOT

TRIG

DL

0.33

µ

F

REF

MAX796

POSITIVE

SECONDARY

OUTPUT

MAIN

OUTPUT

DH

V+

SECFB

2.505V REF

R3

R2

1-SHOT

TRIG

DL

+V

TRIP

WHERE V

REF

(NOMINAL) = 2.505V

= V

REF

(

1 + –––

)

R2

R3

-V

TRIP

R3 = 100k

Ω

(RECOMMENDED)

= -V

REF

(

–––

)

R2

R3

Figure 9. Secondary-Output Feedback Dividers, MAX796 vs. MAX799